High-density planting racks with rails, trays and post-processing and control systems

A control system and planting rack technology, applied in the fields of botanical equipment and methods, gardening tools/equipment, agricultural gas emission reduction, etc., can solve the problem of no processing space, etc., to solve the large labor demand, solve the low processing efficiency, reduce the The effect of farm energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

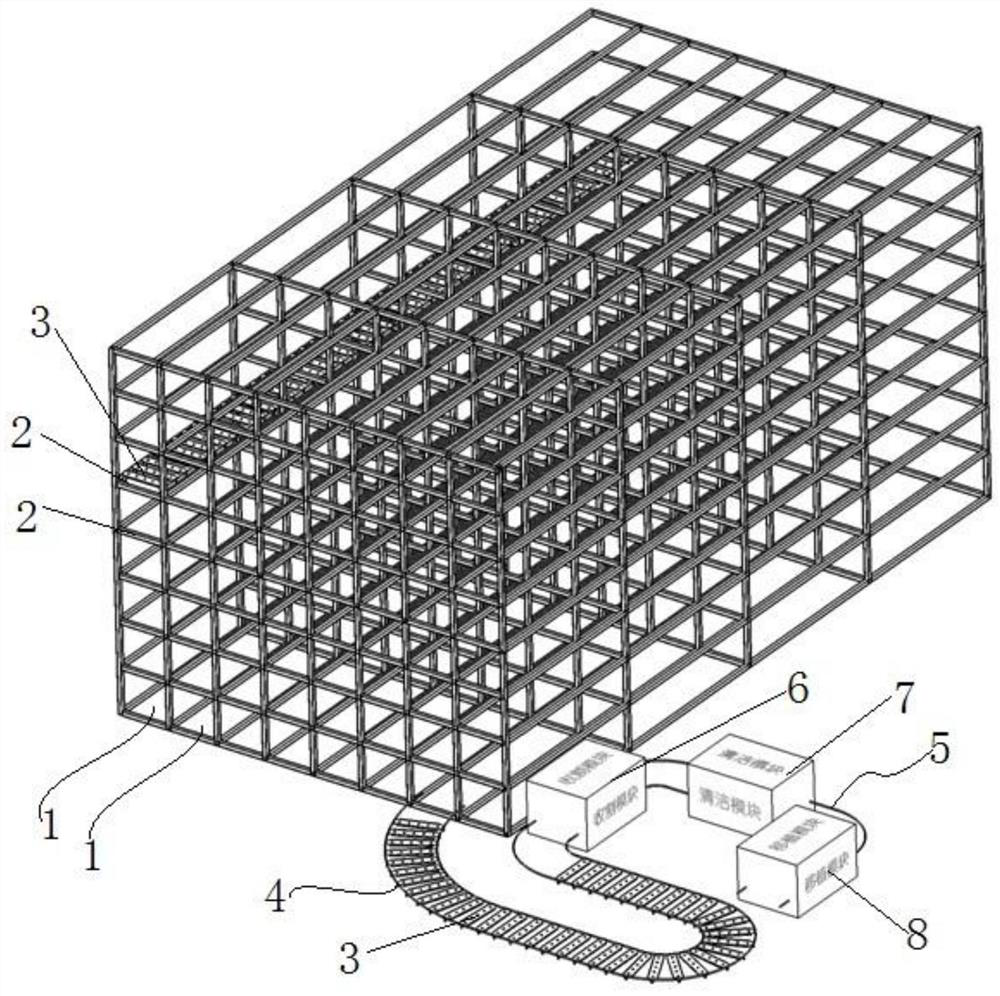

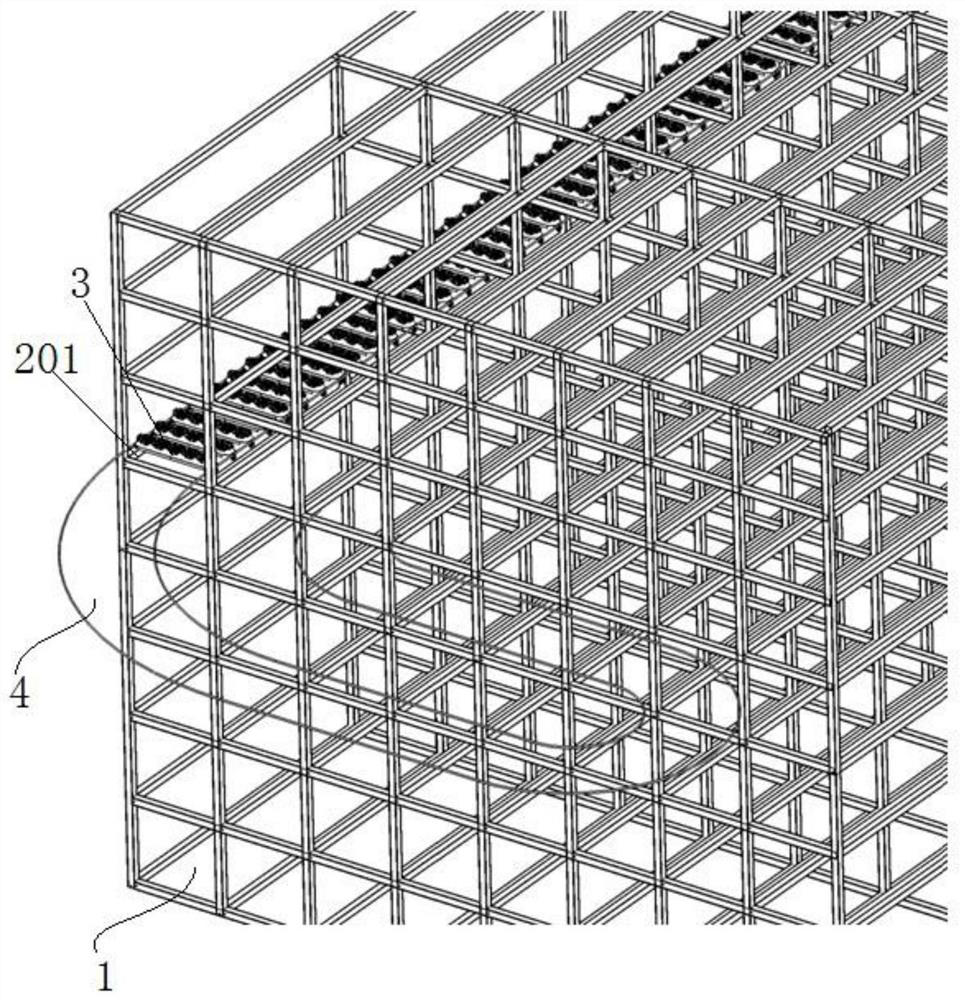

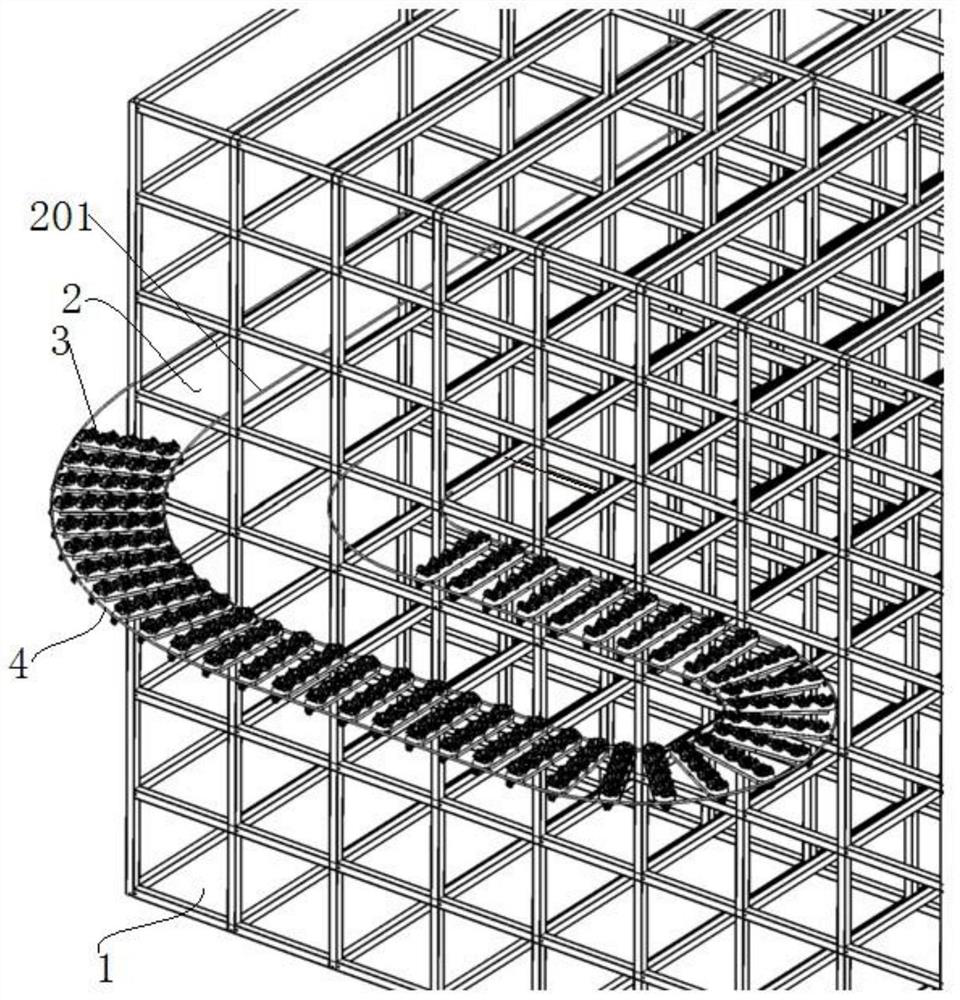

[0074] like Figure 1 to Figure 5 As shown, a high-density planting rack with rails and trays includes a plurality of planting rack units 1, and a plurality of the planting rack units 1 are arranged in an array without gaps, and each of the planting rack units 1 includes several layers of planting Layer 2, the interlayer spacing of several of the planting layers 2 in the same planting frame unit 1 is different; each layer of the planting layer 2 is respectively provided with a planting layer track 201, and the planting layer track 201 passes through the The pulley system 11 is provided with a planting tray 3; the two sides of the planting rack unit 1 are provided with a movable conveying platform 4, and a platform rail is provided on the conveying platform 4, and the platform rail is used for docking the planting layer rail 201; the high-density planting rack further includes a post-processing platform 5 disposed on the periphery of the planting rack unit 1, and the post-proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com