Support element

A technology of supporting components and ring components, which is applied in the direction of bearing components, engine components, bearings, etc., can solve the problems of high failure cost, long failure time, and economical reduction of wind power generation equipment, and achieve the goal of reducing maintenance work and downtime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

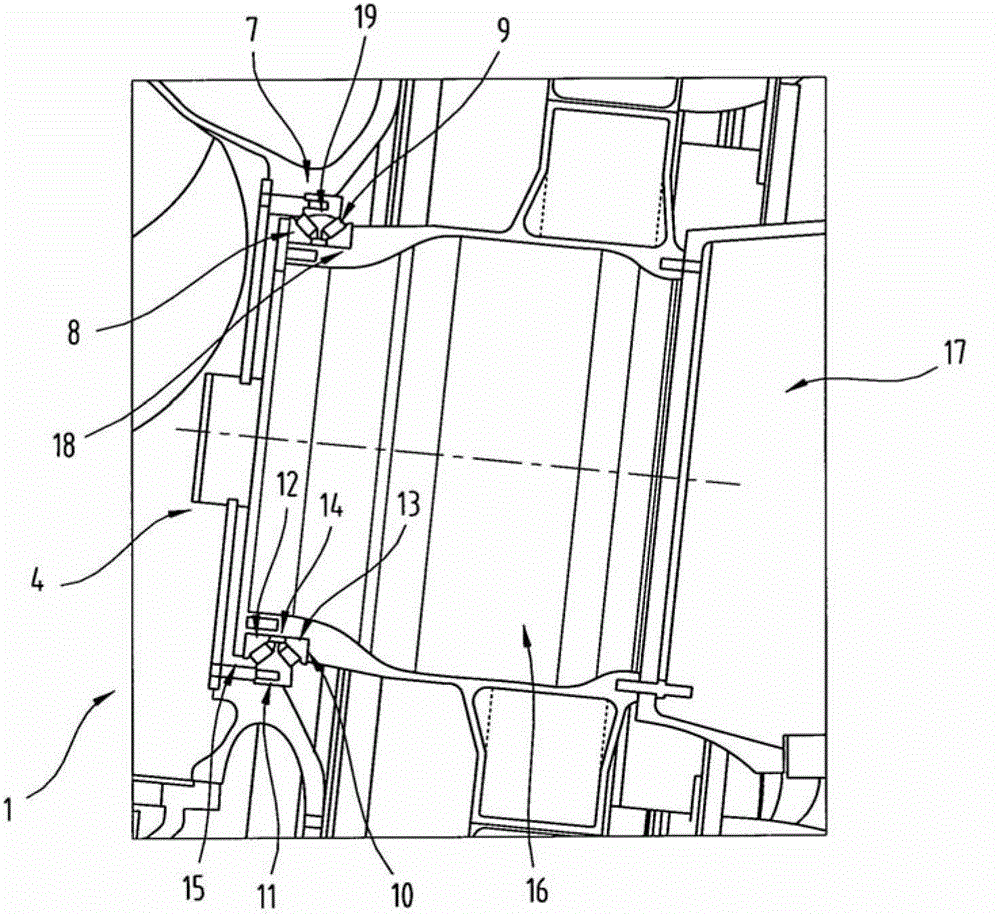

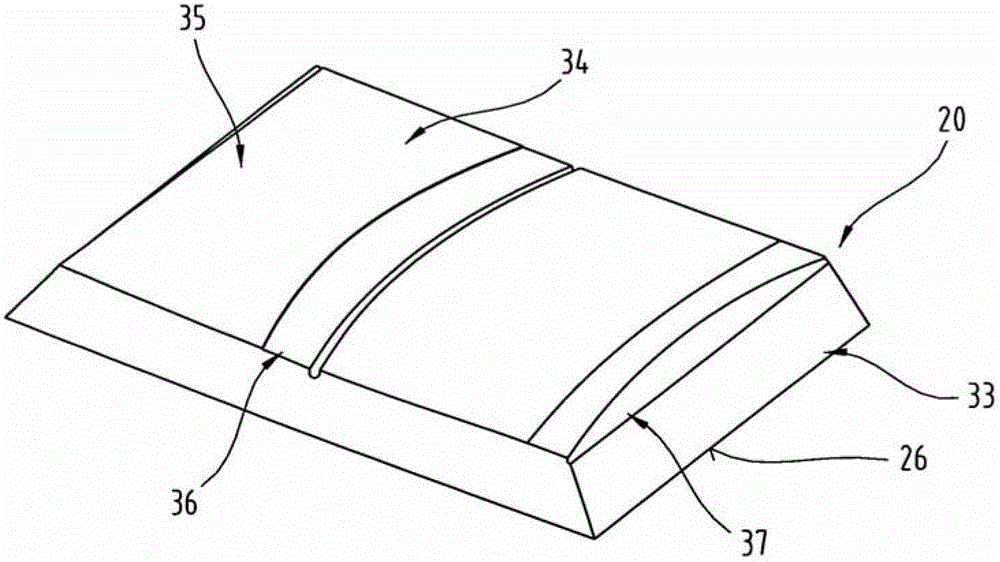

[0042] It should first be understood that the disclosure contained in the entire description can be used without reference to the same parts or the same component reference numerals. Positional designations selected in the description, such as "upper", "lower", "sideward", etc., relate to the directly described and illustrated figure and can be used meaningfully to the new position in the event of a position change. Furthermore, individual features or combinations of features of the various exemplary embodiments shown and described can also themselves be independent solutions according to the invention.

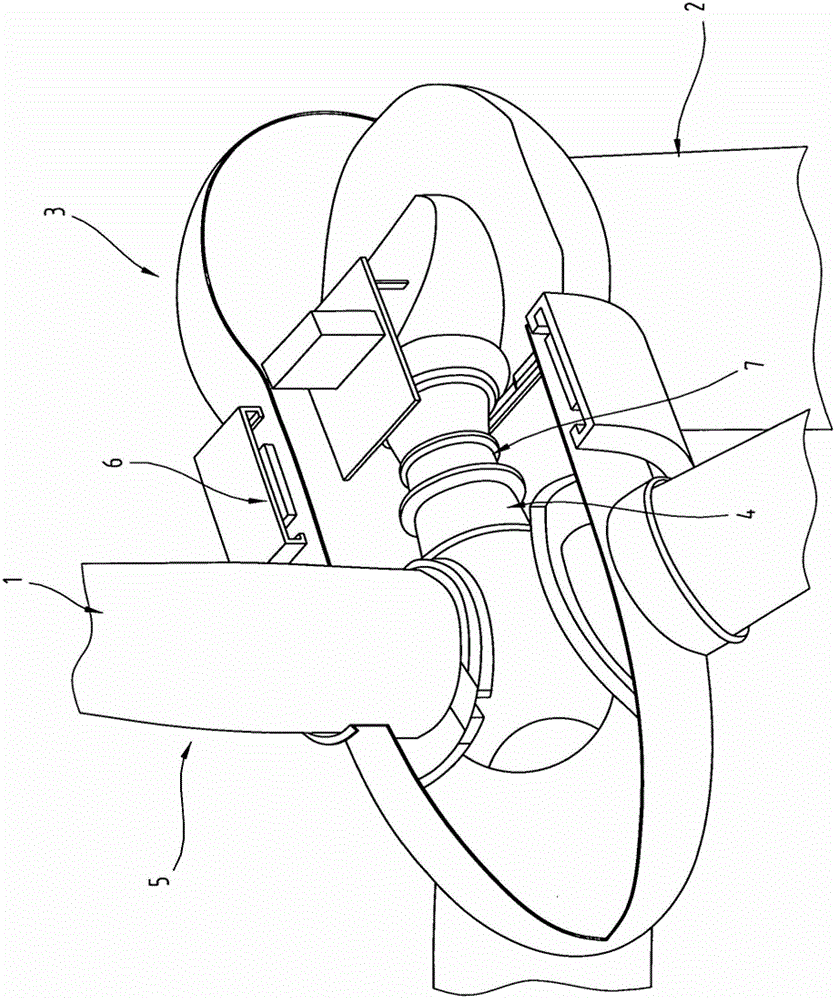

[0043] figure 1 A detail of a wind power plant 1 , as is known in principle from the prior art, is shown in oblique view and partially in section. The wind power plant 1 comprises a tower 2 at the tip of which a pod 3 is arranged. Arranged in this nacelle 3 is a rotor hub 4 which carries rotor blades 5 at one end thereof, in particular in a rotationally movable manner. To ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap