Rotor

一种转子、基体的技术,应用在制造电动马达的转子领域,能够解决昂贵工艺、困难等问题,达到成本低廉、小负担、延长寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

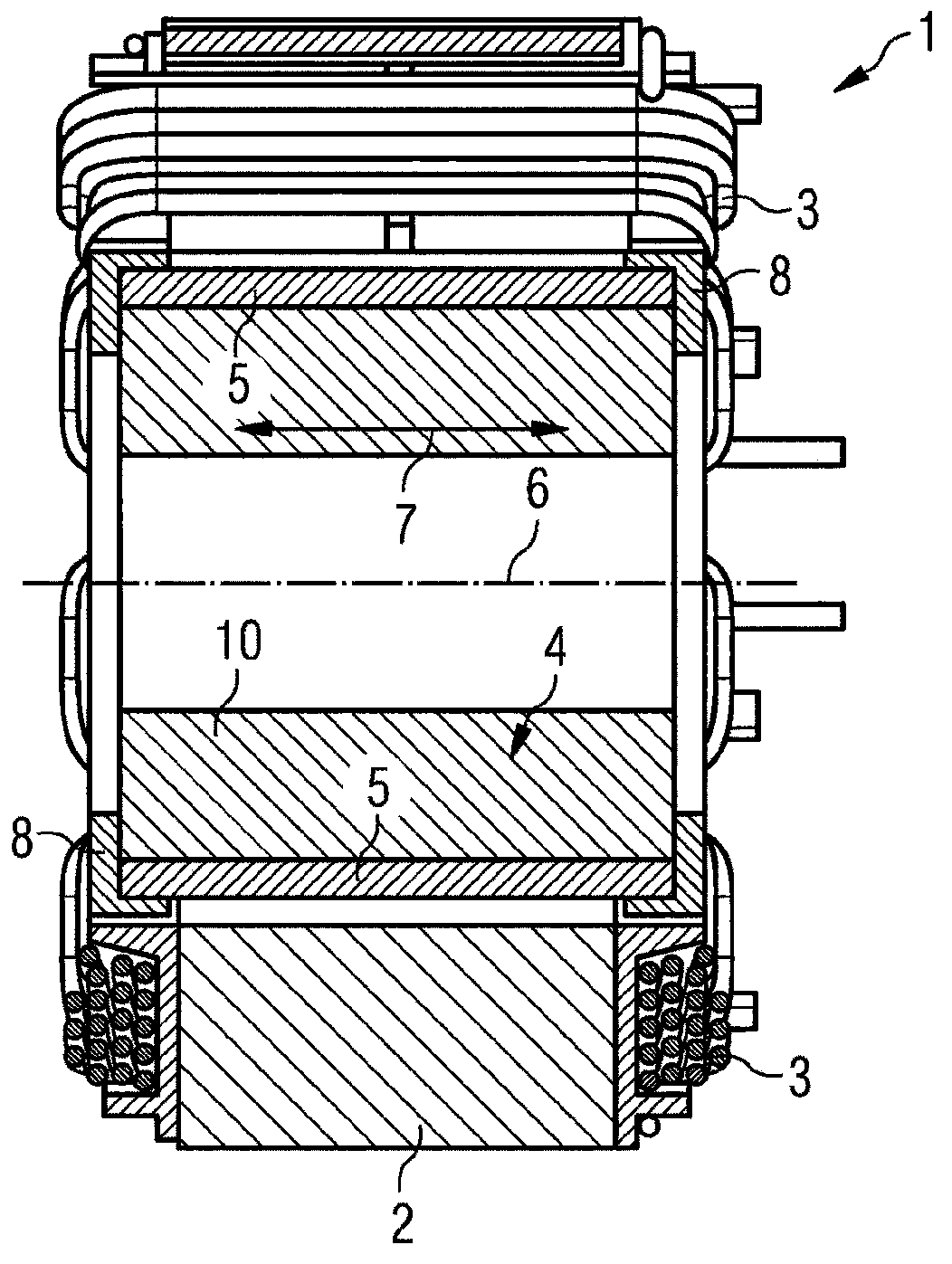

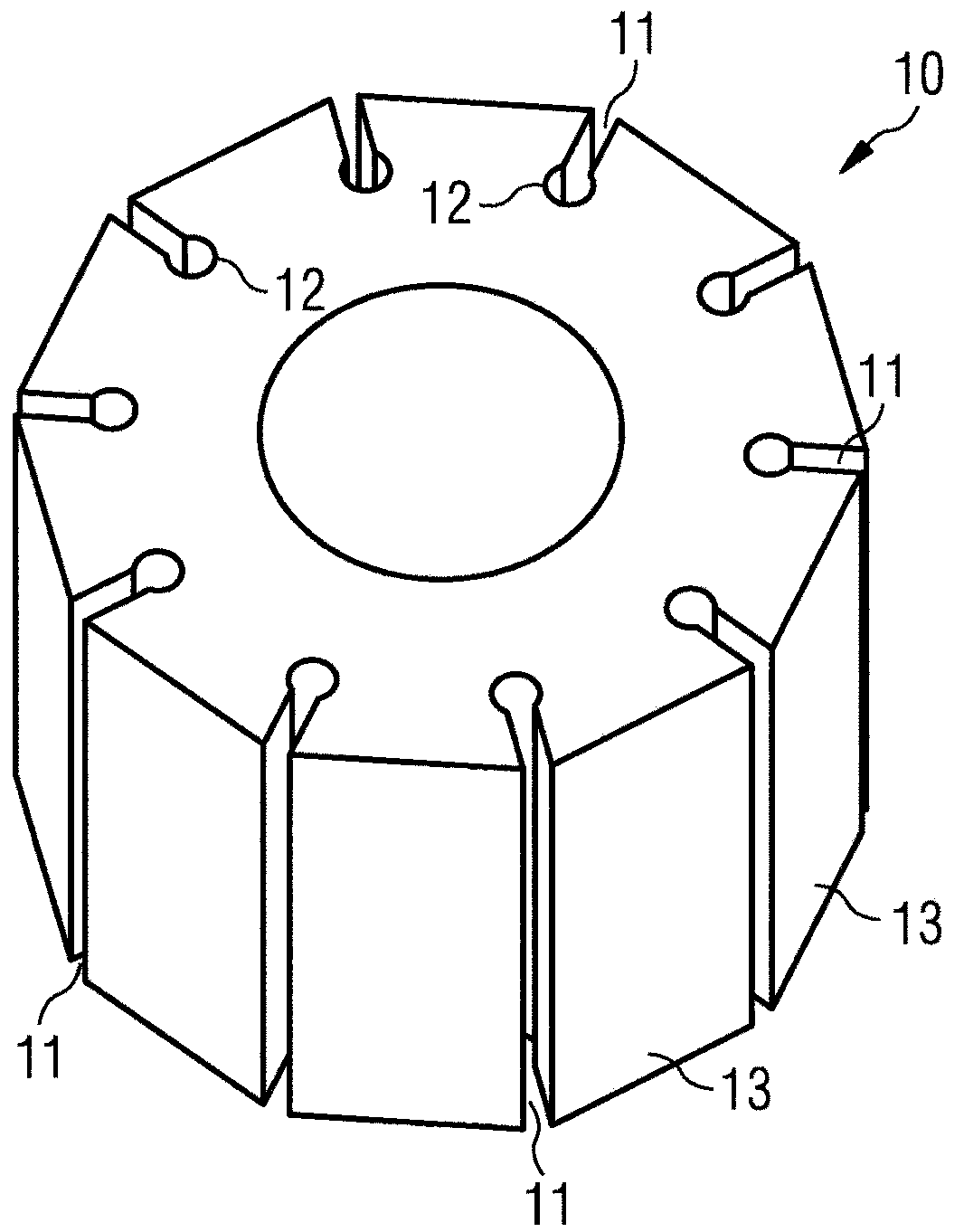

[0021] figure 1 An electric motor 1 with a stator 2 and a rotor 4 is shown. This can be, for example, a so-called reluctance motor. Arranged on the stator 2 are coils 3 which can be passed through with a rectified current, whereby an exchange magnetic field can be generated. The rotor 4 is mounted rotatably on a shaft 6 and has a base body 10 and permanent magnet elements 5 . The permanent magnet element 5 is held on the base body 10 by the connecting sleeve 9 and the locking element 8 . The arrow indicates the axial direction 7 in which, for example, the connecting sleeve 9 can be pushed over the base body 10 . The permanent magnet element 5 is designed here as a square, which is a particularly cost-effective design. However, it can also be embodied in the form of a housing.

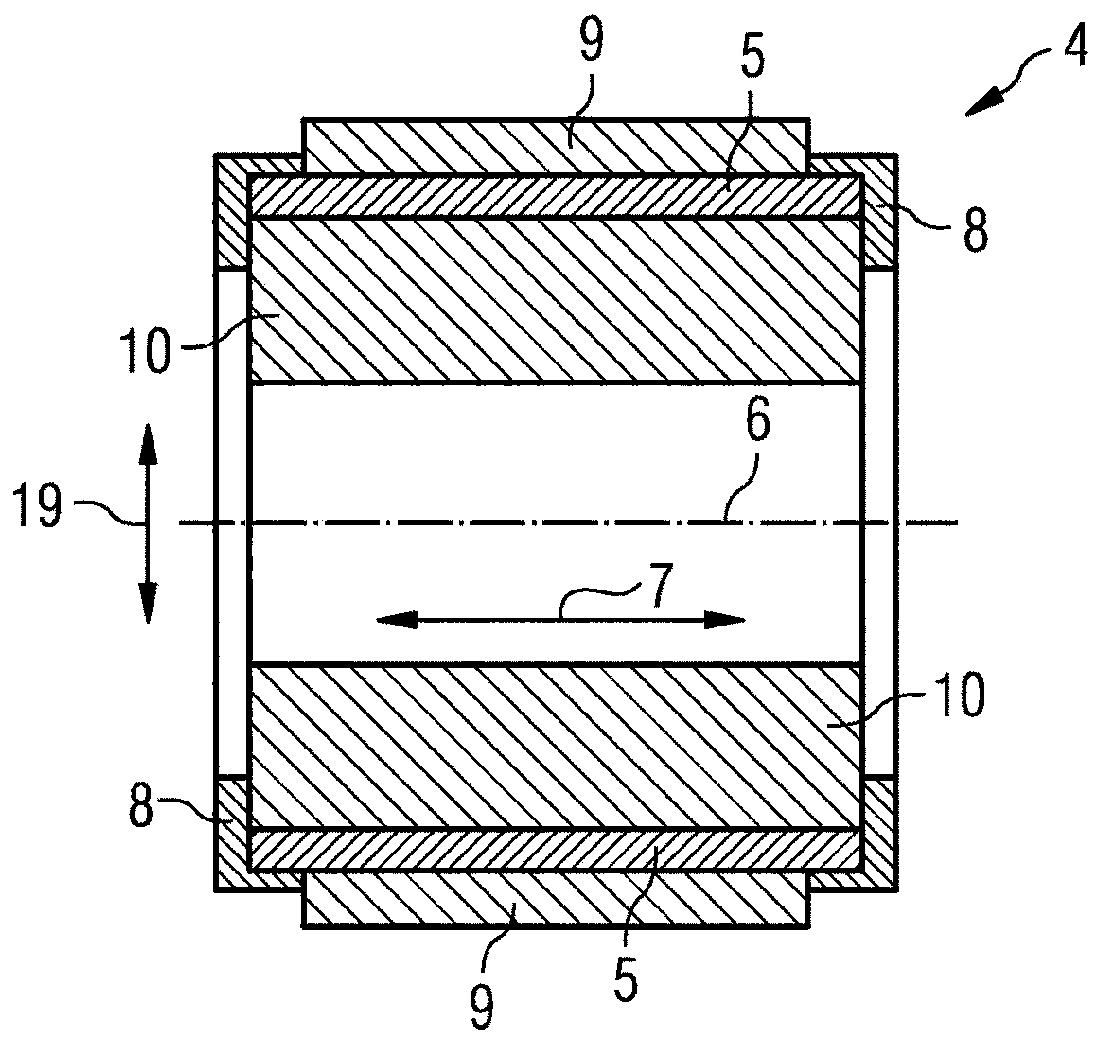

[0022] exist figure 2 The construction of the rotor 4 is shown in more detail in . It can be seen that there are a number of permanent magnet elements 5 which are arranged on the cylindrical out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com