Method for preparing bamboo charcoal facial cleanser

A facial cleanser and bamboo charcoal technology, which is applied in the field of daily chemicals, can solve the problems of cleaning performance, moisturizing performance, skin anti-oxidation and anti-sensitivity, irreversible skin damage, degreasing of skin epidermis, etc., to achieve enhanced Skin anti-oxidation and anti-sensitivity, even and thorough emulsification, and the effect of reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

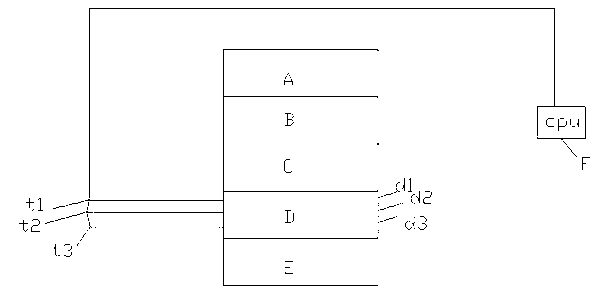

[0035] Bamboo charcoal powder preparation: Pilot test is carried out in a vertical moving bed dry distillation carbonization furnace, with bamboo chips (about 36cm long) with an average moisture content of 39%, the temperature of each temperature measurement point, the drying area A is 150 ° C, and the pre-carbonization area B is 275°C, carbonization zone C is 450°C, observed when the temperature rises figure 1 The zone D shown is the temperature of different positions in the combustion zone. When the temperature of a certain place in the combustion zone, such as d2, is too low, open the small hole in that place, introduce air and burn it nearby, so as to raise the temperature in this place and control the bamboo to move down. The temperature of the combustion zone experienced in the process was raised to 700°C at a rate of 5°C / min and kept for 40 minutes, and then raised from 700°C to 1100°C at a rate of 5°C / min and held for 2 hours. The bamboo charcoal cooling pipe and bamboo...

Embodiment 2

[0045] Preparation of bamboo charcoal powder: Pilot test was carried out in a 16-tube conjoined moving bed dry distillation carbonization furnace, with Mengzong bamboo chips (about 40cm long) with an average moisture content of 30%, the temperature of each temperature measurement point, and the drying area A was 200 ℃, the pre-carbonization zone B is 270℃, and the carbonization zone C is 500℃. When the temperature rises, part of the combustion gas introduced from the external combustion type and the non-condensable gas of the bamboo vinegar liquid condenser are combusted at the same time, so that the temperature of the combustion zone is 15℃ / min. Raise the temperature to 750°C at a rate of 15°C / min and keep it warm for 80 minutes, then raise the temperature from 750°C to 1500°C at a rate of 15°C / min and hold it for 8 hours, spray water vapor into the 1500°C area for 60 minutes, and use natural bamboo charcoal cooling pipes and bamboo vinegar liquid condensers Cooling, the disch...

Embodiment 3

[0054] The preparation of bamboo charcoal powder is with embodiment one. Then the prepared bamboo charcoal is prepared into bamboo charcoal powder with a particle diameter of 150nm.

[0055] The preparation method of the tea juice is as follows: (1), firstly, wash and pulverize the witch hazel and the tea leaves, wherein the tea leaves are cooked Pu-erh tea and white tea mixed at a ratio of 1:1.5; Hazel and tea leaves are added to deionized water and fully soaked for 1.5 hours, then poured into a countercurrent extractor for extraction to obtain a crude filtrate; the crude filtrate is initially filtered with a precision filter membrane containing a polypropylene fiber membrane filter element, and the crude filtrate is removed. (2) Perform ultrafiltration on the preliminary filtrate, and then concentrate the ultrafiltration permeate at 40°C with a reverse osmosis membrane to obtain the first concentrate with a solid content of 15%. Take half of the first concentrated solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap