Shock absorption connecting mechanism for electromobile

A connection mechanism, technology of electric vehicles, applied in the direction of vehicle components, cantilevers mounted on pivots, suspensions, etc., can solve the problems of different steering arm angles, different wheel tracks, waste of materials and time, etc., and achieve material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

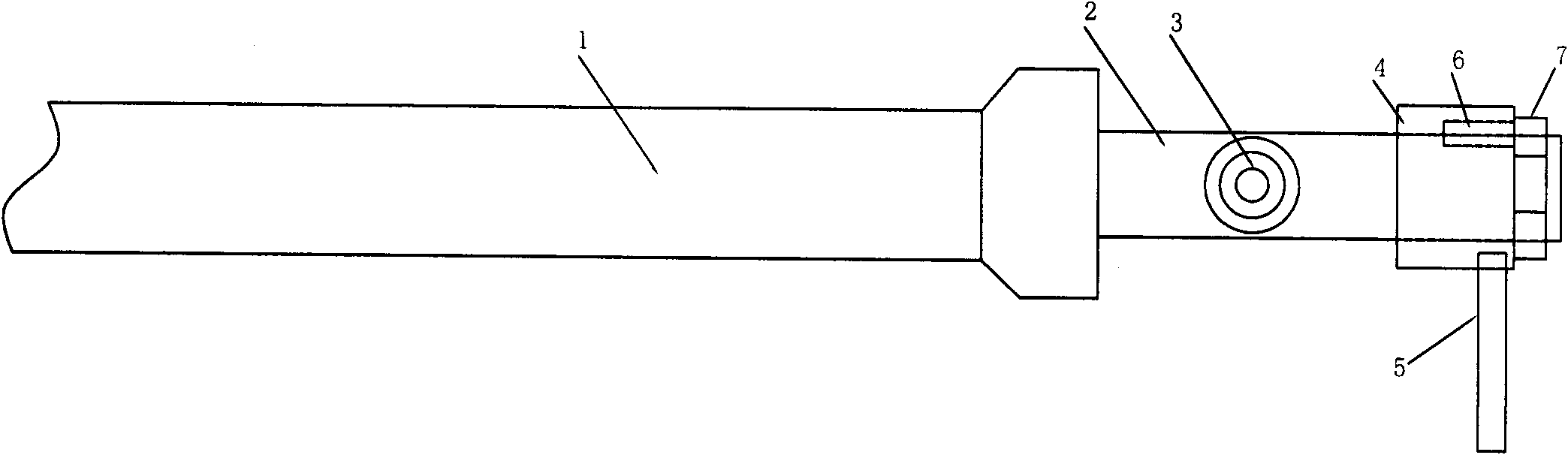

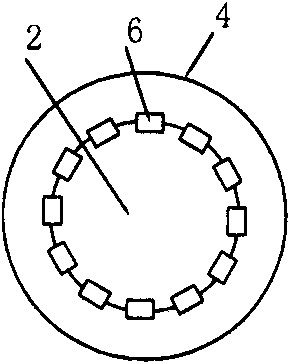

[0010] Such as figure 1 As shown, the shock absorbing connection mechanism of the electric vehicle includes an outer sleeve 1, a steering damping shaft 2, a wheel fixing shaft 3, a steering arm 5, and a steering arm connecting pipe 4. The steering damping shaft 2 is arranged in the outer sleeve 1, and the steering The shock absorber shaft 2 is provided with twelve keyways in the circumferential direction, the wheel fixing shaft 3 is fixed on the steering shock absorber shaft 2, the steering arm 5 is fixed on the steering arm connecting pipe 4, and the steering arm connecting pipe 4 is sleeved on the steering shock absorbing shaft 2 Above, the inner wall of the steering arm connecting pipe 4 is also provided with twelve key grooves in the circumferential direction, the steering damping shaft 2 and the steering arm connecting pipe 4 are fixed in the circumferential direction by keys 6, and the end of the steering damping shaft 2 is provided with threads , the steering arm connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com