Method for preparing high-purity sulfuric acid solvent used for para-aramid spinning

A technology of para-aramid spinning and sulfuric acid, which is applied in the field of chemical engineering, can solve the problems of high price, increased production cost of para-aramid production enterprises, and inability to be directly used as a solvent for para-aramid spinning, so as to get rid of Dependence, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

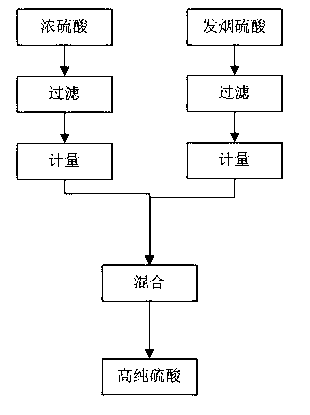

Image

Examples

Embodiment 1

[0018] Using commercially available 98 acid (the actual concentration is 96.5% after testing) and 20% oleum (calculated as sulfuric acid, the actual test concentration is 104.5%), 98 acid and 20% oleum are passed through the basket filter respectively Filtration, gear pump delivery, and mass flowmeter metering, 98 acid at a flow rate of 9 mass parts / hour and 20% oleum at a flow rate of 7 mass parts / hour, simultaneously enter the static mixer and mix to form a high-purity sulfuric acid. After testing, the actual concentration is 99.8%.

Embodiment 2

[0020] Using commercially available 98 acid (the actual concentration is 96.5% after testing) and 50% oleum (calculated as sulfuric acid, the actual test concentration is 111.3%), 98 acid and 50% oleum are passed through the basket filter respectively Filtration, gear pump delivery, mass flow meter metering, 98 acid at a flow rate of 11.5 parts by mass / hour and 50% oleum at a flow rate of 3.5 parts by mass / hour, simultaneously enter the static mixer and mix to form a high-purity sulfuric acid. After testing, the actual concentration is 99.9%.

Embodiment 3

[0022] Using commercially available 98 acid (the actual concentration is 96.5% after testing) and 65% oleum (calculated as sulfuric acid, the actual test concentration is 114.5%), 98 acid and 65% oleum are passed through the basket filter respectively Filtration, gear pump delivery, mass flow meter metering, 98 acid at a flow rate of 14.5 parts by mass / hour and 65% oleum at a flow rate of 3.5 parts by mass / hour, simultaneously enter the static mixer and mix to form a high-purity sulfuric acid. After testing, the actual concentration is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com