A method for producing road asphalt from super heavy oil

A technology for road asphalt and super-heavy oil, applied in the field of super-heavy oil production of road asphalt, can solve the problems of large evaporation loss and affecting the quality of asphalt products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

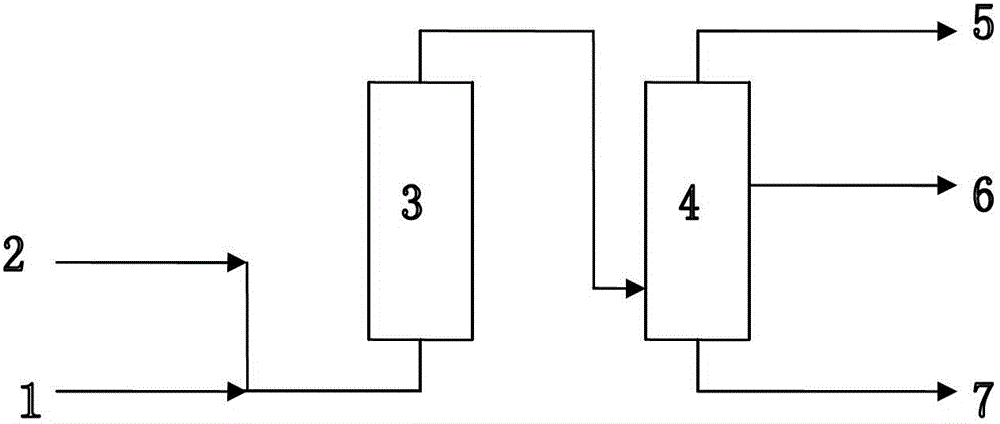

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Add a certain amount of atmospheric residue of low-wax heavy oil to Liaohe super heavy oil

[0019] Add 10m%, 5m% low-wax heavy oil atmospheric residues a and b respectively to Liaohe ultra-heavy oil, and carry out small test in the laboratory. The reaction temperature is 380°C and the residence time is 100 minutes. The resulting oil Real boiling point distillation is carried out to obtain asphalt, and its properties meet the AH-90 technical requirements of GB / T15180-2010, wherein the mass changes in the film oven test are 0.15m% and 0.23m%, respectively.

[0020] Contrast 1: The mass change of AH-70 bitumen obtained by direct distillation of Liaohe super heavy oil is 1.31m% in the film oven test; Liaohe super heavy oil is obtained by direct distillation of atmospheric residue a of low-wax heavy oil added with 10m% In the film oven test of AH-70 asphalt, the mass change is 1.22m%. Liaohe ultra-heavy oil is subjected to real boiling point distillation at the re...

Embodiment 2

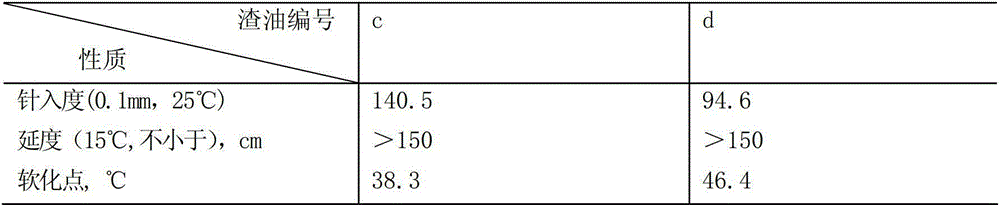

[0021] Example 2 Adding a certain amount of vacuum residue of low-wax heavy oil to Liaohe super heavy oil

[0022] Add 8m% and 20m% of vacuum residue c and d of low-wax heavy oil to Liaohe ultra-heavy oil respectively (see the table for properties), and conduct a small test in the laboratory. The reaction temperature is 365°C and the residence time is 200 minutes. The resulting oil is distilled at the real boiling point to obtain asphalt, and its properties meet the technical requirements of AH-70 and AH-90 of GB / T15180-2010, wherein the mass change of AH-70 in the film oven test is 0.10m%, 0.09m%; AH -90 is 0.17m% and 0.13m%, respectively.

[0023] Contrast 2: The mass change of AH-70 bitumen obtained by direct distillation of Liaohe super heavy oil is 1.31m% in the film oven test; the reaction temperature of Liaohe super heavy oil is 365°C, the residence time is 200 minutes, and the resulting oil is tested for true boiling point The bitumen obtained by distillation meets th...

Embodiment 3

[0024] Example 3 The decompression wax oil of a certain amount of low-wax heavy oil added to Liaohe super heavy oil

[0025] Add 6m% and 12m% of the second- and third-line distillates of low-wax heavy oil to Liaohe ultra-heavy oil respectively (see the table for properties), and conduct a small test in the laboratory. The reaction temperature is 410°C and the residence time is 40 minutes. The resulting oil is subjected to true boiling point distillation to obtain asphalt, whose properties meet the technical requirements of AH-70 and AH-90 of GB / T15180-2010, wherein the mass changes of AH-70 in the film oven test are 0.05m% and 0.04m% respectively; AH-90 is 0.08m%, 0.07m%, respectively.

[0026] Contrast 3: The mass change of the AH-70 bitumen obtained by the direct distillation of Liaohe super heavy oil is 1.31m% in the film oven test; Liaohe super heavy oil is reacted at 410°C and the residence time is 40 minutes, and the resulting oil is tested for true boiling point The bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com