Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

A technology of yield strength and hot-rolled plate, applied in the field of hot-rolled steel plate and manufacturing, can solve the problems of process extension, high cost, and low yield, and achieve the effect of good plate shape, obvious cost advantage, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

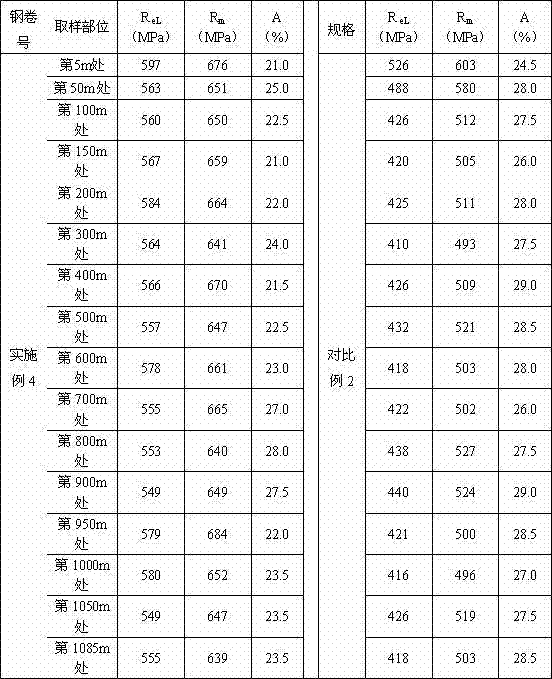

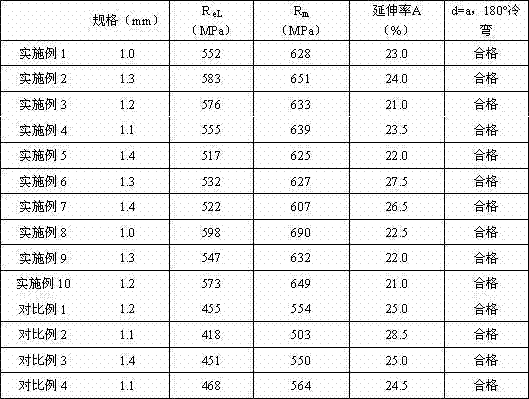

Examples

Embodiment Construction

[0045] The present invention is described in detail below.

[0046] Each embodiment of the present invention is produced according to the following steps:

[0047] Hot metal desulfurization→converter blowing→argon blowing→LF furnace refining→continuous casting→rotary descaling→soaking furnace soaking→high pressure water descaling→7-stand finishing rolling→laminar cooling→coiling; and control the following parameters:

[0048] Two-stage liquid core pressing is adopted during continuous casting, and the thickness of the billet is reduced from 90~100mm to 50~55mm;

[0049] Control descaling high pressure water pressure to 30~38MPa;

[0050] The temperature of the soaking furnace is controlled at 1180~1250°C;

[0051] The pass reduction rate and rolling temperature of each pass of the 7-stand finish rolling are: F1: 50~60%, 1040~1080℃; F2: 50~60%, 1000~1050℃; F3: 40~50 %, 960~1030℃; F4: 40~50%, 940~990℃; F5: 25~35%, 930~980℃; F6: 20~35%, 890~960℃; F7: 10~20%, 870~930℃;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com