Working machine

A technology for working machines and working devices, applied in mechanical equipment, earthmoving machines/shovels, fluid pressure actuating devices, etc. The effect of heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

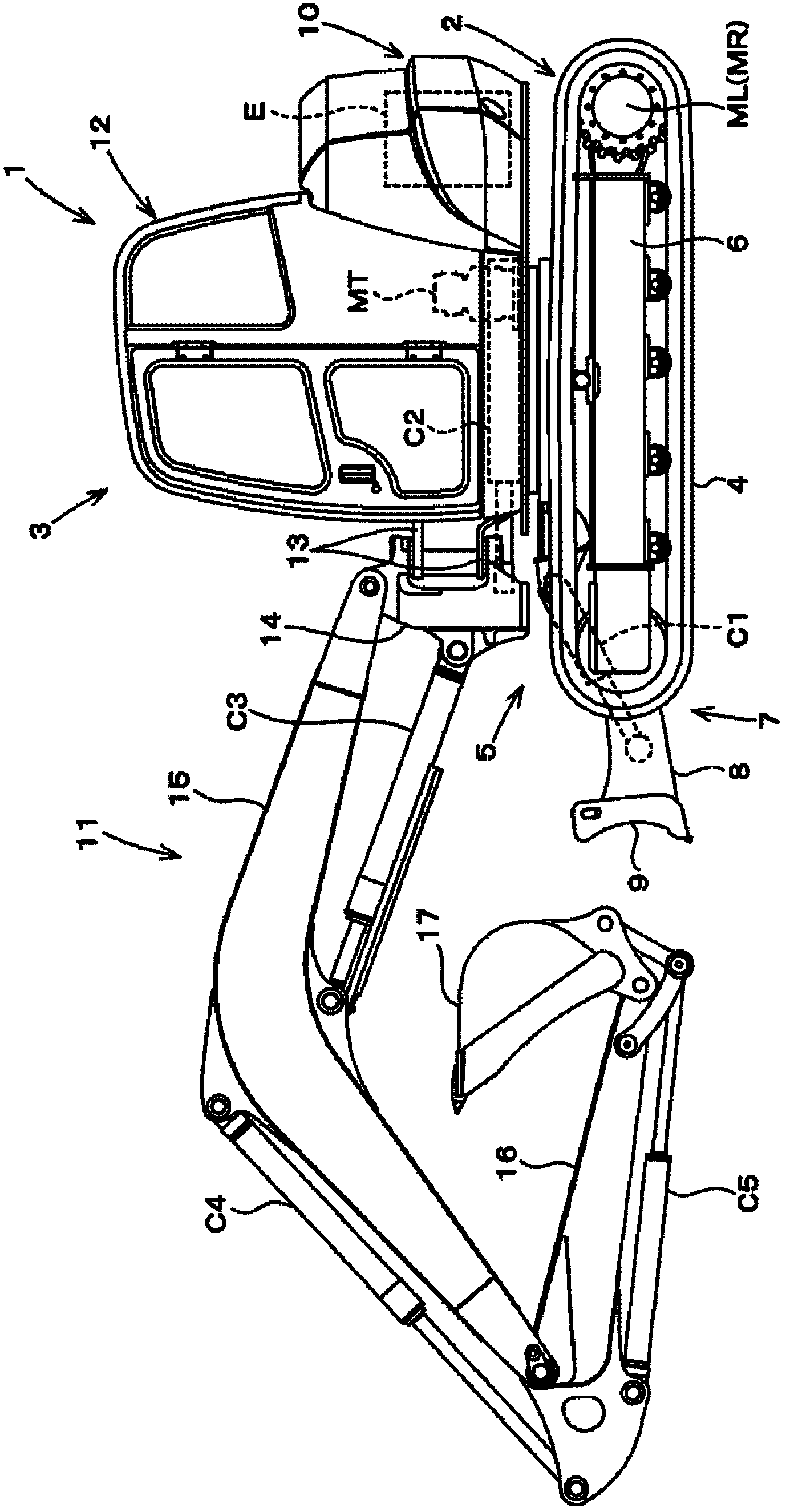

[0110] Figure 1 to Figure 7 represents the first embodiment of the present invention, in figure 1 Among them, reference numeral 1 is a backhoe excavator (working machine). The backhoe excavator 1 is mainly composed of a lower traveling body 2 and a vehicle mounted on the traveling body 2 so that it can rotate around a rotation axis in the up-and-down direction. The upper rotating body 3 constitutes.

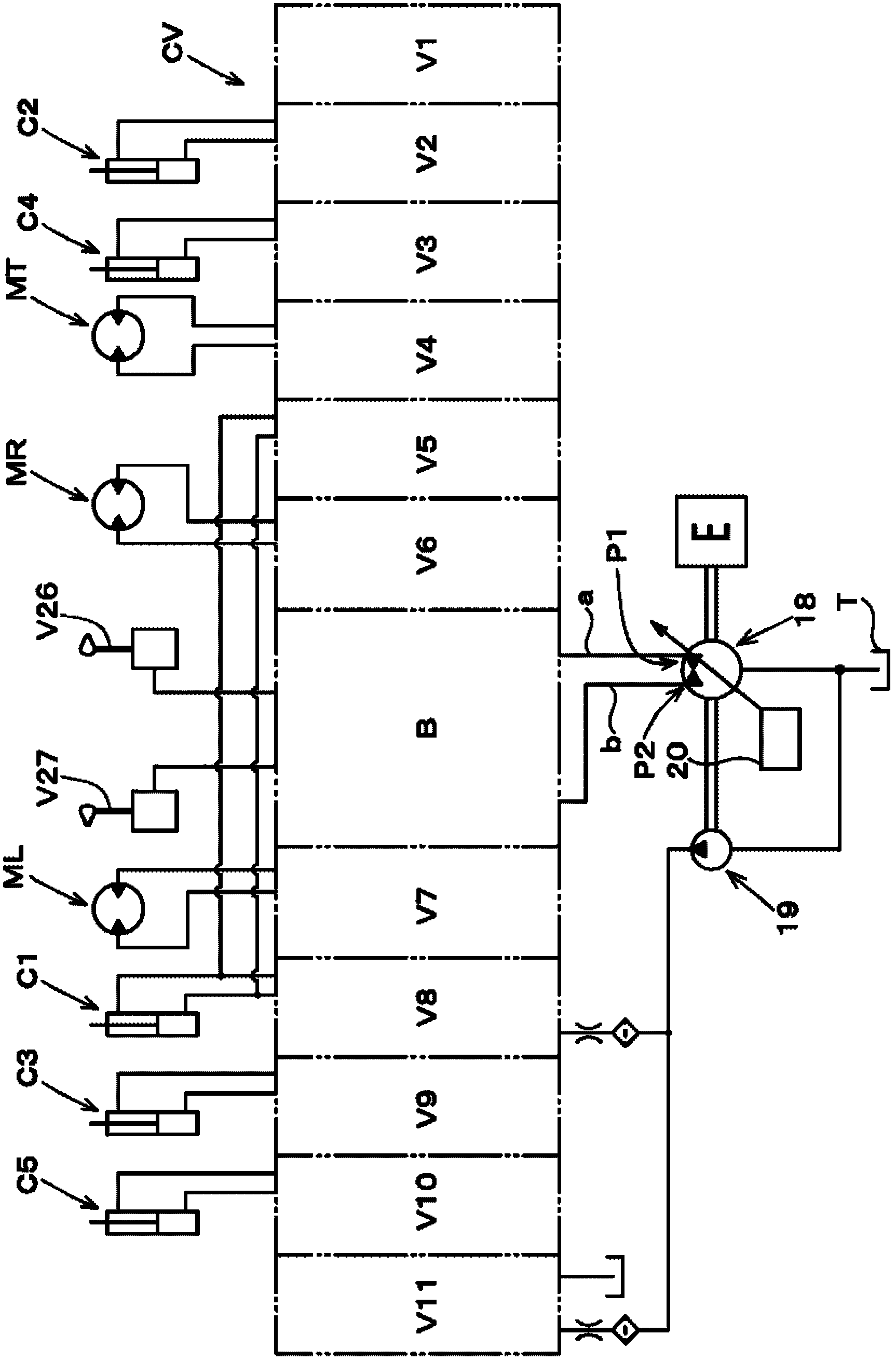

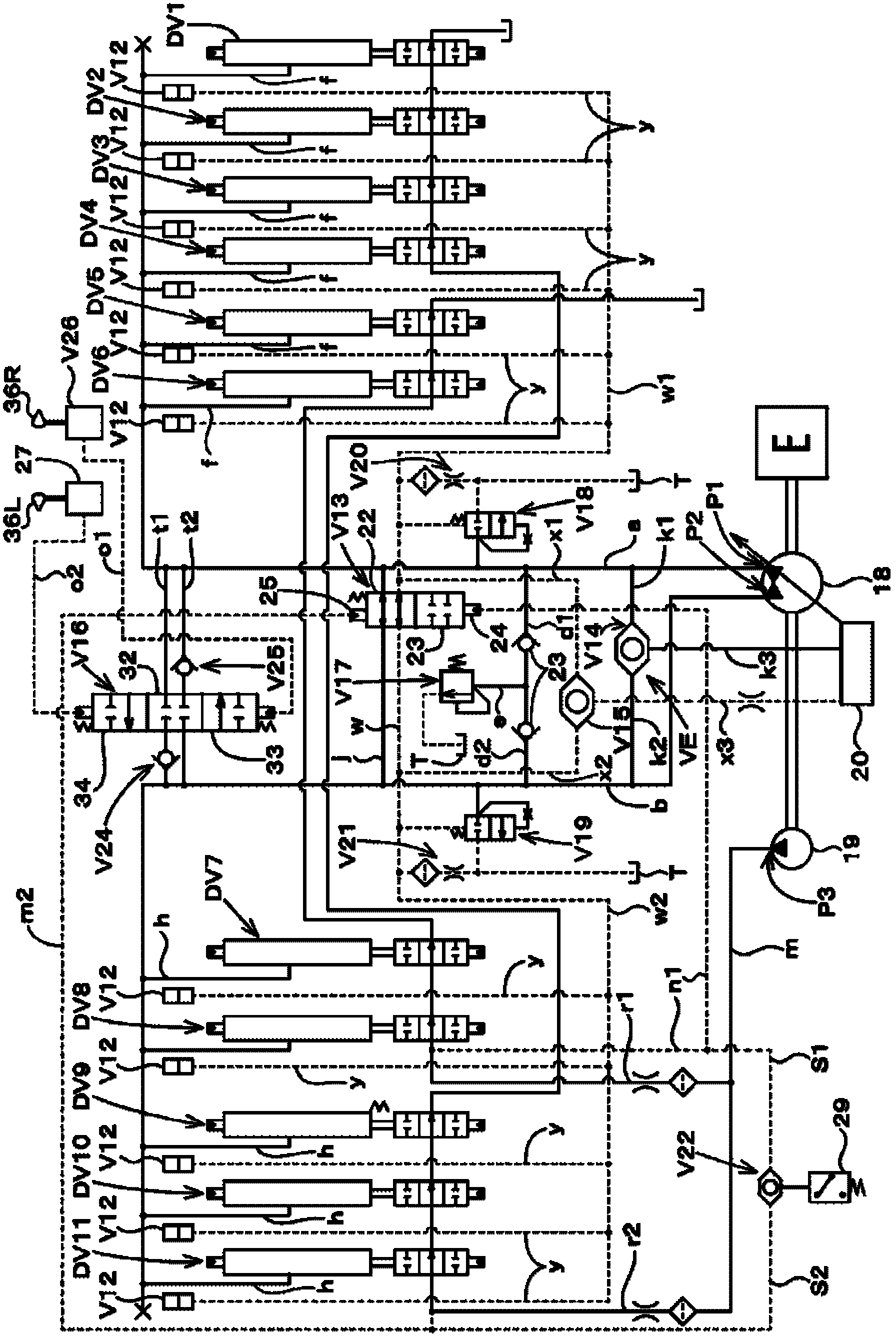

[0111] The traveling body 2 has a crawler-type traveling device 5 on the left and right sides of the crawler frame 6, and the crawler-type traveling device 5 is configured such that the endless crawler belt 4 is driven around by traveling motors ML and MR composed of hydraulic motors (hydraulic actuators). Move to the loop.

[0112] A bulldozing device 7 is arranged at the front portion of the crawler frame 6 . The rear end side of the bulldozing device 7 is pivotally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com