Liquid level measuring device

A liquid level measuring device and liquid level technology are applied in the direction of determining specific gravity by measuring pressure difference and displaying liquid level indicator by pressure measurement, which can solve the problems of large error of double-chamber balance container, difficult installation and large measurement error, etc. , to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

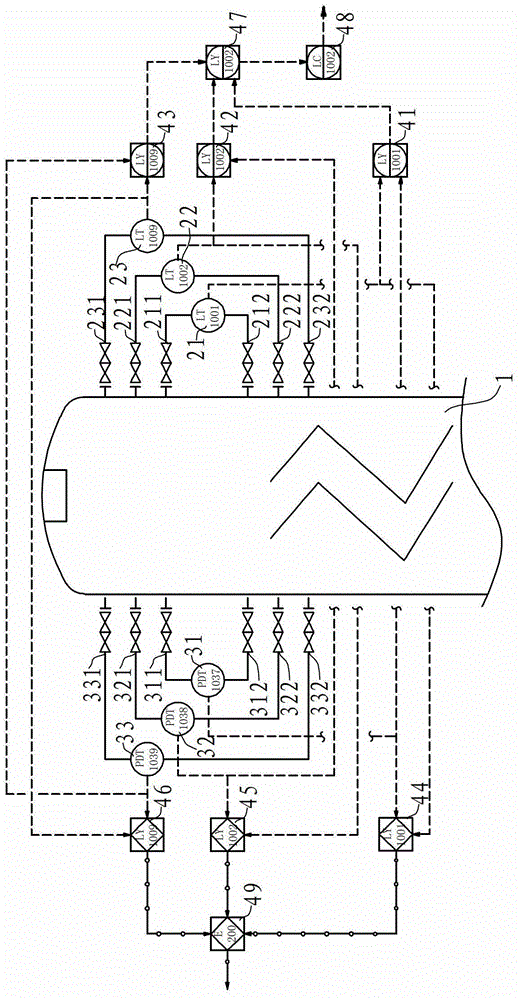

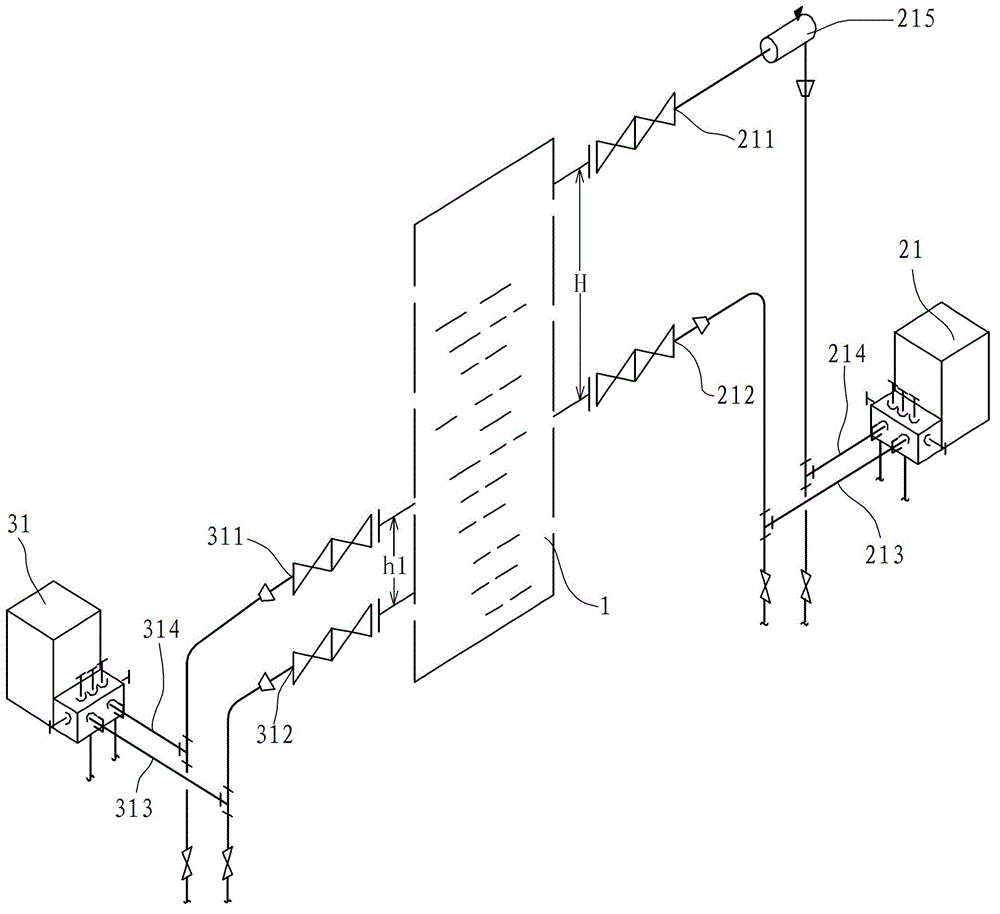

[0015] see figure 2 , a liquid level measuring device, used to measure the liquid level of the syngas cooler 1, the syngas cooler 1 is vertical, when it is running, in this embodiment, the liquid level fluctuates between 0 ~ 6600mm, its The normal operating temperature of the internal steam is 327°C and the pressure is 12.3MPaG, and the maximum operating temperature is 350°C and the pressure is 13.5MpaG.

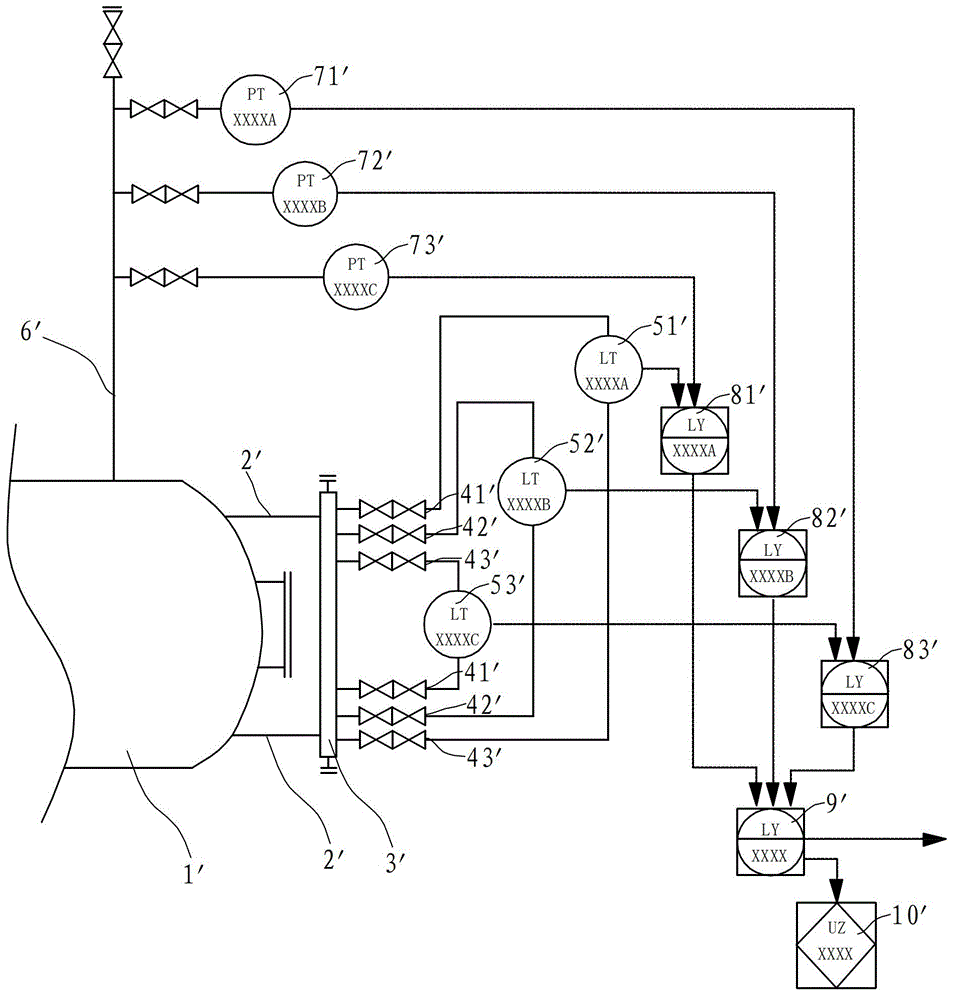

[0016] Three liquid level transmitters are provided, the first liquid level transmitter 21, the second liquid level transmitter 22 and the third liquid level transmitter 23 to measure the density of the syngas cooler 1 water; pressure transmitter, the first differential pressure transmitter 31, the second differential pressure transmitter 32 and the third differential pressure transmitter 33 to measure the density of water in the syngas co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com