Automatic inspection device for wire rods

A technology of automatic inspection and take-up device, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low inspection efficiency, inability to guarantee product quality, defective or defective products are not detected, etc., to achieve simple operation, compact structure, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

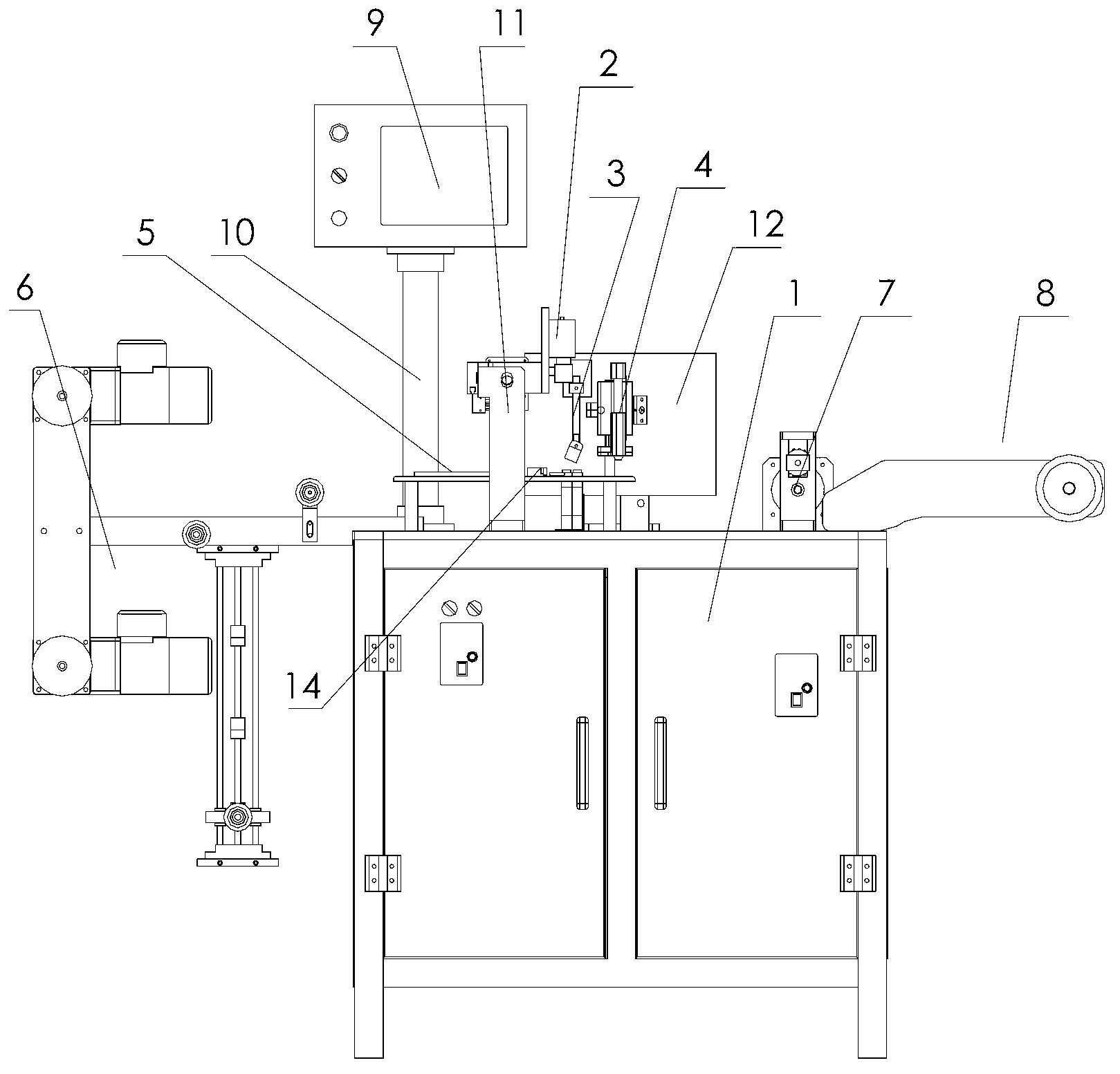

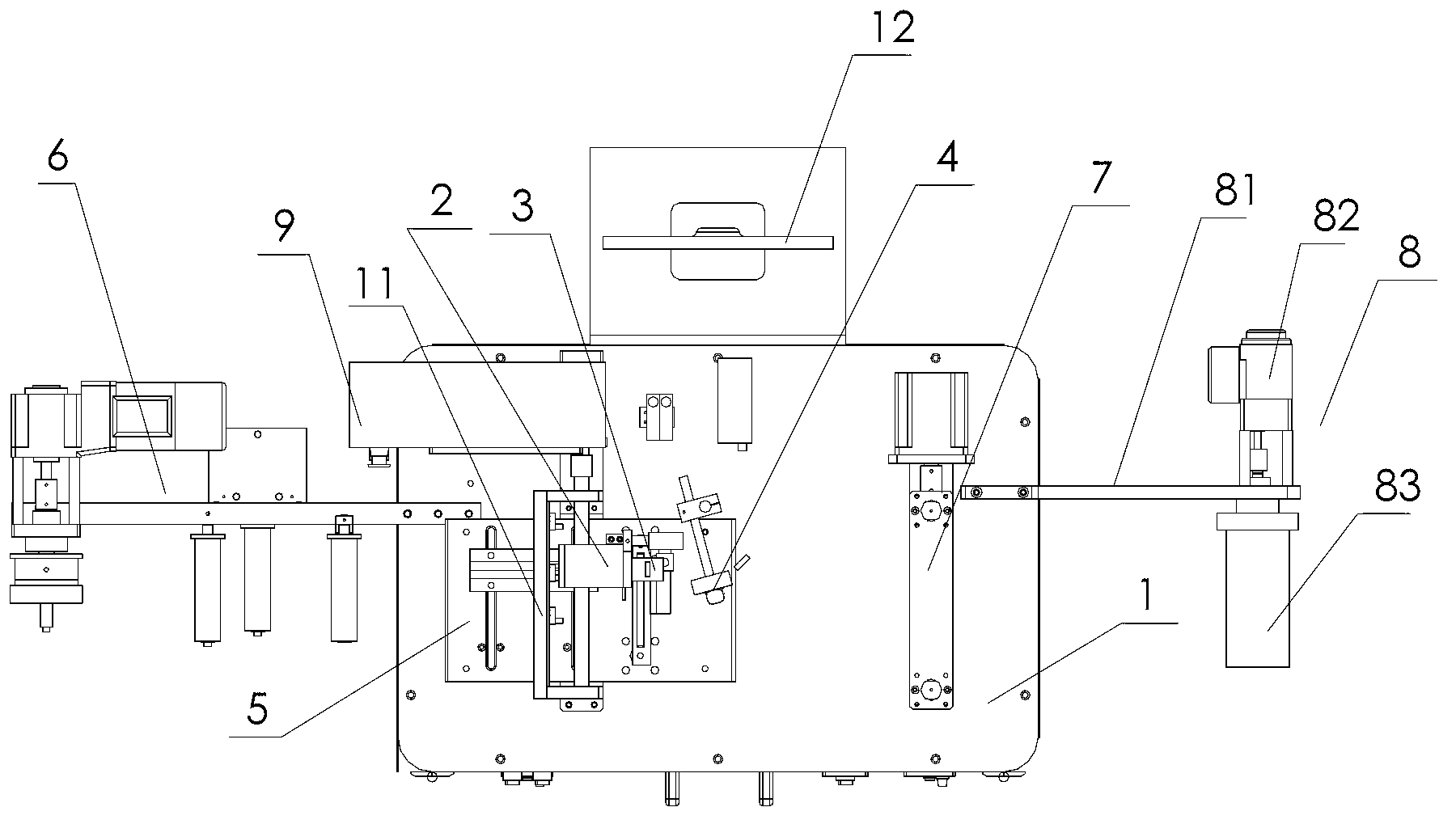

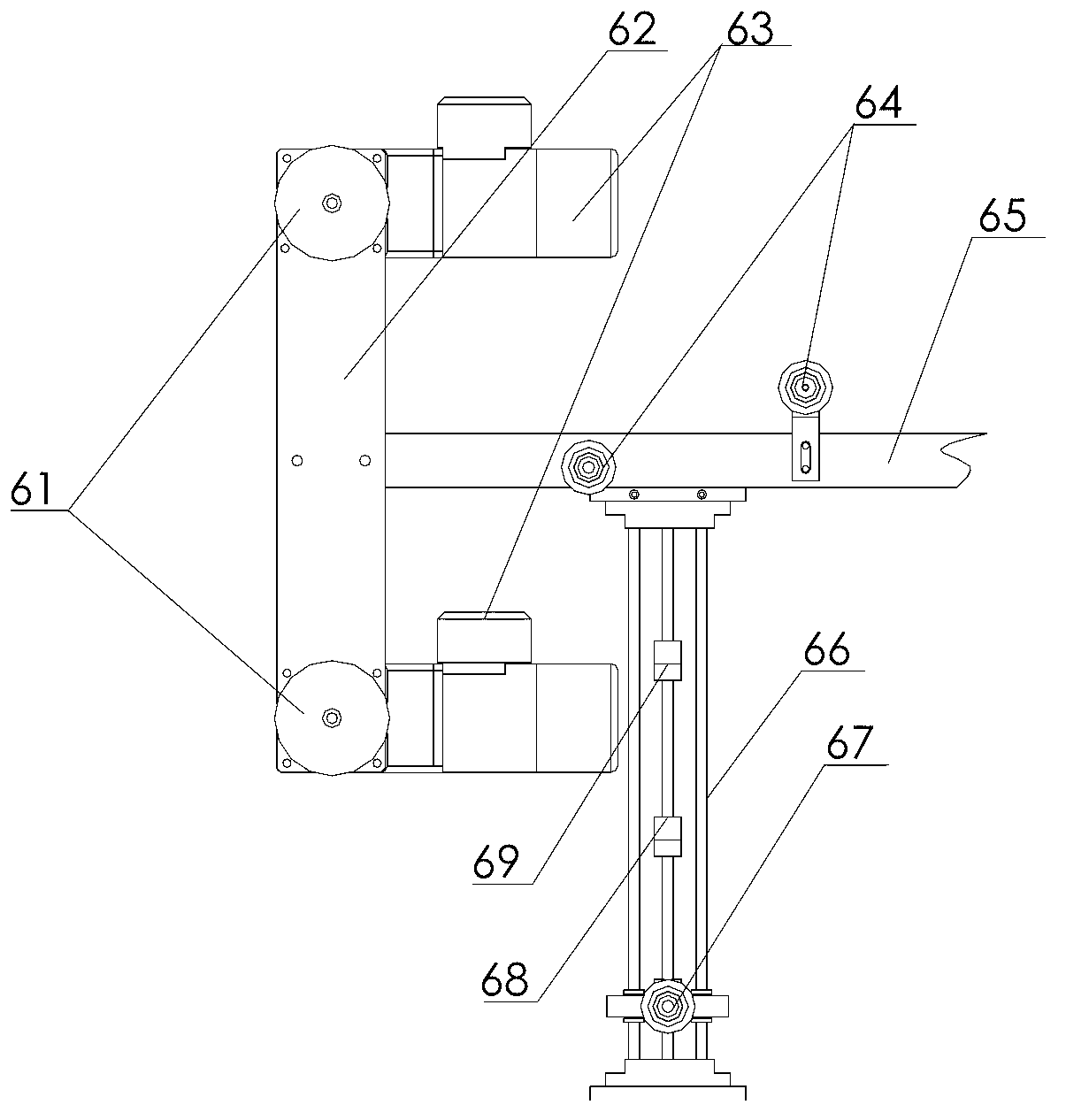

[0023] Embodiment 1: refer to Figure 1~9 . An automatic wire inspection device, comprising a control cabinet 1, a CCD visual inspection module 2, an LED light source 3, a marking module 4, a wire fixing plate 5, an automatic wire pay-off device 6, a traction device 7, a wire take-up device 8 and an operation panel 9 , the left side of the upper end of the control cabinet 1 is provided with an automatic wire pay-off device 6, and the right side of its upper end is provided with a wire take-up device 8 driven by a wire take-up motor 82, and the wire fixing plate 5 is set on the upper end of the control cabinet 1, and the wire fixing plate 5 From left to right, there are CCD visual inspection module 2, LED light source 3, and marking module 4 in order at the top. The operation panel 9 is set above the control cabinet 1 through the column 10. The control cabinet 1 between the wire fixing plate 5 and the wire take-up device 8 The top is provided with traction device 7.

[0024] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap