A method of using an automatic drawing machine for testing the fastness of the connection between the needle handle and the needle body

A drawing machine and needle handle technology, which is applied in the field of automatic drawing machines, can solve problems such as single function, complex structure, and inability to detect fastness, and achieve the effect of ensuring enterprise benefits and avoiding false detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

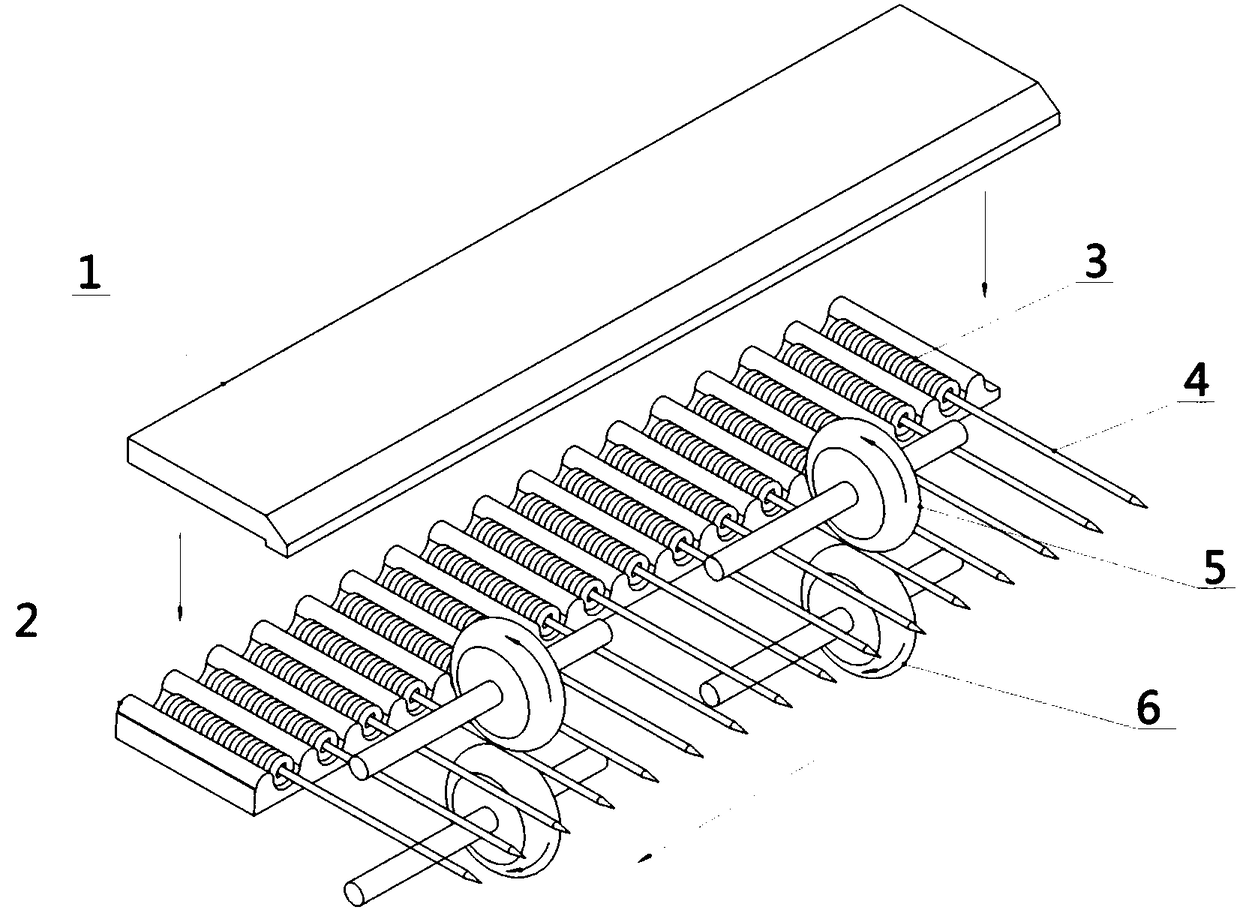

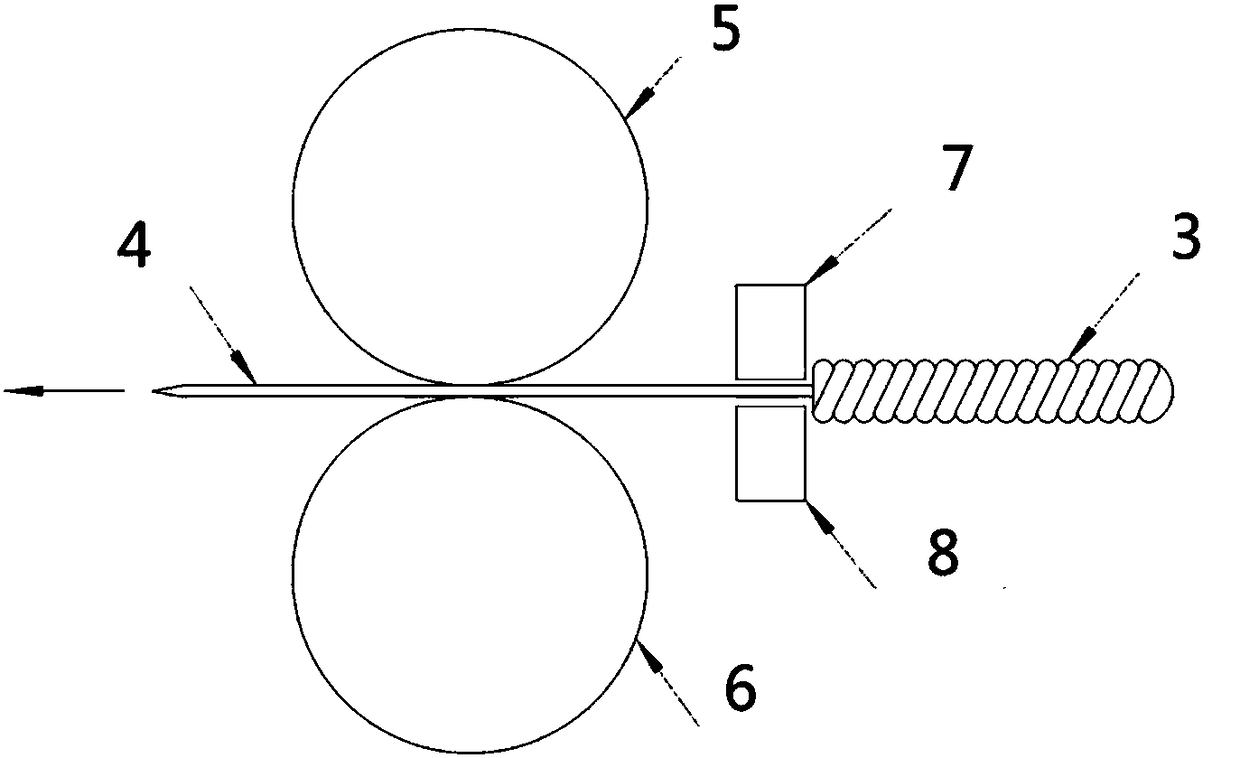

[0044] Due to the high output and variety of acupuncture needles, it is impractical to manually inspect the fastness of each acupuncture needle. The random inspection method is generally used, but there must be missed inspections in the random inspection method, and there will be acupuncture needles with excessive fastness, which will cause damage to the enterprise. In order to solve this problem, the present invention proposes an automatic drawing machine for testing the fastness of the connection between the needle handle and the needle body, which includes the needle feeding part, and also includes the drawing structure, the storage tank and the driving part, wherein, A cover plate 1 is provided above the conveyor belt 2, and the cover plate 1 is used to block dust or foreign matter, so as to prevent acupuncture needles from jumping out of the groove for some reason, affecting safe production; grooves are uniformly arranged on the conveyor belt 2, and the grooves The length ...

Embodiment 2

[0061]A certain type of acupuncture needle has a handle 3 with a diameter of 1.1 mm and a length of 15 mm; a needle body 4 with a diameter of 0.16 mm and a length of 30 mm, and a standard fastness of 8N. Adopt the drawing machine described in embodiment 1 to check the fastness, wherein, the arc diameter of the groove on the conveyor belt 2 is 2mm, the width of the conveyor belt 2 is 20mm, and the dynamometer used is a digital dynamometer. The device is a single-chip microcomputer, the motor is a speed-regulating motor, and the processor is connected to the touch-screen display, so that the conveyor belt 2 can be directly set on the touch-screen display, and the pressure and speed of each group of upper rollers 5 and lower rollers 6 can be adjusted. The first set of rollers is 7.5N, the second set of rollers is 8N, the third set of rollers is 8N, and the fourth set of rollers is 8.5N. The material of the roller is rubber. During long-term operation, the surface of the roller sh...

Embodiment 3

[0063] A certain type of acupuncture needle has a handle 3 with a diameter of 1.3mm and a length of 15mm; a needle body 4 with a diameter of 0.3mm and a length of 40mm, and a standard fastness of 15N. Adopt the drawing machine described in embodiment 1 to check the fastness, as long as the pressure and speed of each group of upper rollers 5 and lower rollers 6 are adjusted, and the digital tension meter is used to check, the first group of rollers is 14N, and the second group of rollers is 15N. , the third set of rollers is 16N, and the fourth set is 16.5N. All the other parts are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com