Opening/closing tool and pouch provided with same

A technology of opening and closing parts and opening and closing devices, which is applied in the direction of closing devices, can solve the problems of incomplete sealing, difficulty in opening, and inability to install small bags, etc., and achieve the effects of simple structure, improved sealing, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

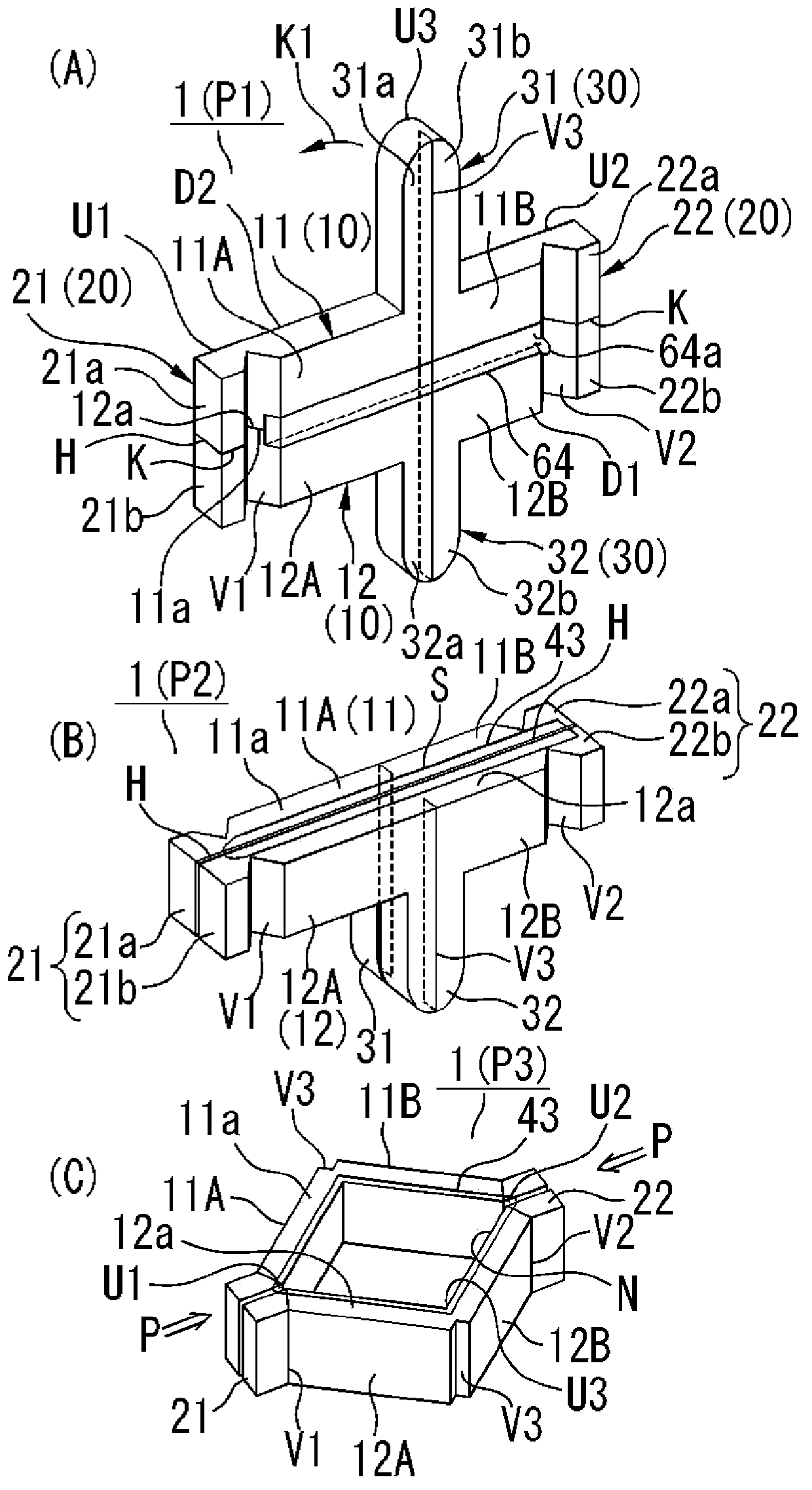

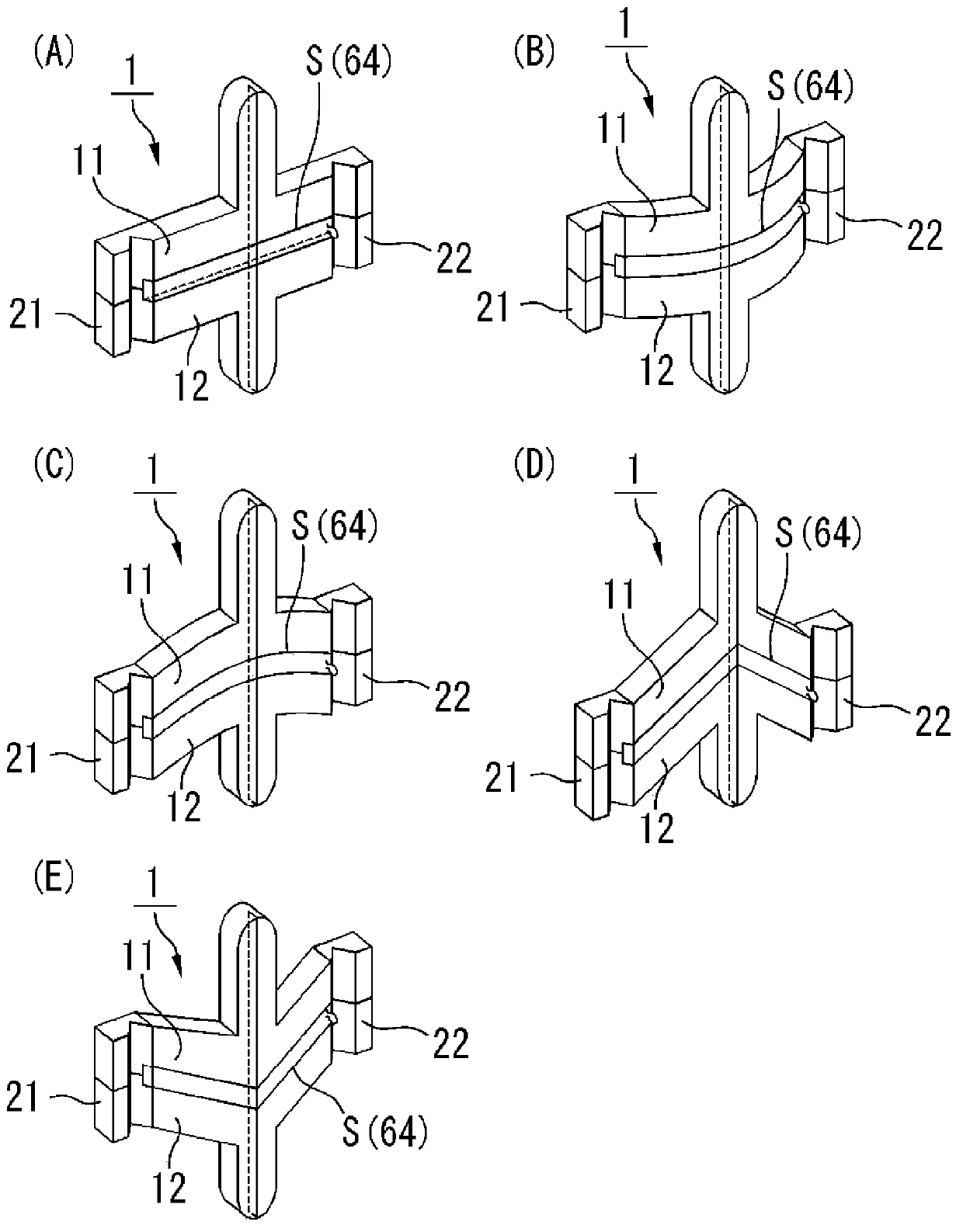

[0083] refer to figure 1 , the opening and closing tool 1 according to Embodiment 1 to which the present invention can be applied will be described. figure 1 It is a perspective view explaining the shutter 1, (A) is a diagram showing the shutter 1 in a state arranged at the closed position P1, (B) is a diagram showing the shutter 1 in a state arranged at the standby position P2, ( C) is a figure which shows the opening-closing tool 1 of the state arrange|positioned in the open position P3. also, figure 1 In (C), illustration of the handle parts 31 and 32 is omitted.

[0084] Among them, the closed position P1 is a position where the outlet T of the bag Y described later is closed (closed), the open position P3 is a position where the contents stored in the bag Y can be taken out by opening the outlet T, and the standby position P2 is The position in the middle of moving from the closed position P1 to the open position P2, or conversely, from the open position P2 to the clos...

Embodiment approach 2

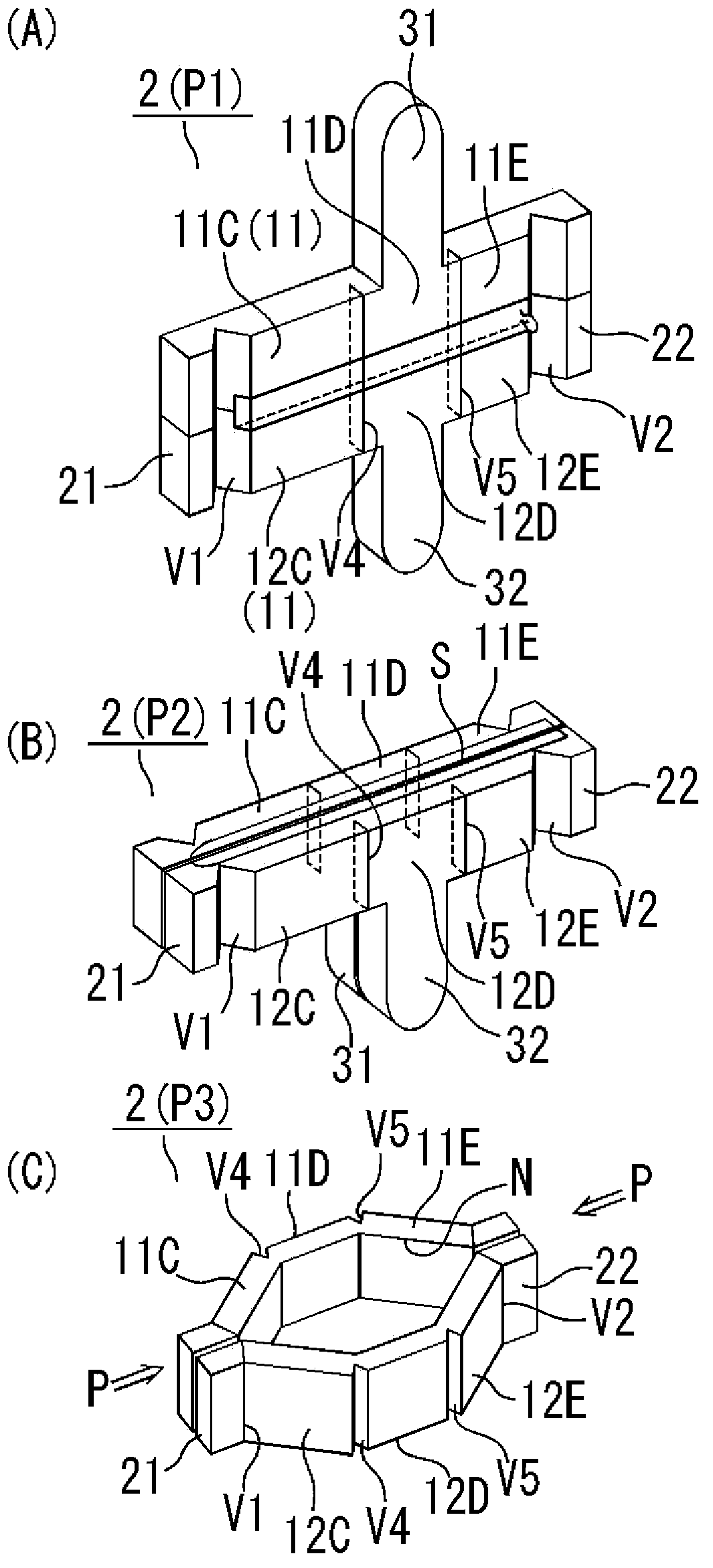

[0170] refer to Figure 24 ~ Figure 36 , the opening and closing tool 1 according to Embodiment 2 to which the present invention can be applied will be described.

[0171] in, Figure 24 It is a figure explaining the shutter 1, (A) is a perspective view of the shutter 1 arrange|positioned at the closed position P1, (B) is the figure which looked at the shutter 1 from the arrow M1 direction in (A), (C) It is a perspective view of the shutter 1 disposed at the open position P2, and (D) is a view of the shutter 1 viewed from the arrow F1 direction on the left in (C). and, Figure 25 It is a diagram explaining the state where the opening and closing tool 1 is attached to the bag (pouch) Y, (A) is a front view, (B) is a view along the line M3-M3 in (A), and (C) is a view explaining how to take out the bag Y. A graph of exit T. and, Figure 26 It is a figure explaining the opening and closing operation of the opening and closing member 1, Figure 26 (A)~(C) and Figure 25 (A)...

Embodiment approach 3

[0206] refer to Figure 37 , the opening and closing tool 87 according to Embodiment 3 to which the present invention can be applied will be described. in, Figure 37 (A) is a perspective view of the shutter 87 disposed at the closed position P1 , and (B) is a perspective view of the shutter 87 disposed at the open position P2 (standby position P1 ′).

[0207] The opening and closing tool 87 includes a pair of unsealing parts 91 and 92 opposed to each other through a slit S, hinge parts 93 and 94 connecting both ends thereof, and a handle extending outward from the unsealing parts 91 and 92 . Sections 95, 96. The unsealing parts 91 and 92 are configured to extend linearly. On the other hand, the hinge parts 93 , 93 are configured to be bent toward the front side (surface side) at the ends of the unsealing parts 91 , 92 . A cutout K corresponding to the slit S is formed on the surface side of the hinge parts 93, 94, and is divided into parts 93a, 93b and parts 94a, 94b by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com