Harvester

A harvester and body technology, which is applied in the directions of harvesters, dryers, cutters, etc., to achieve the effects of being conducive to operation, simple installation structure, and bright lighting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

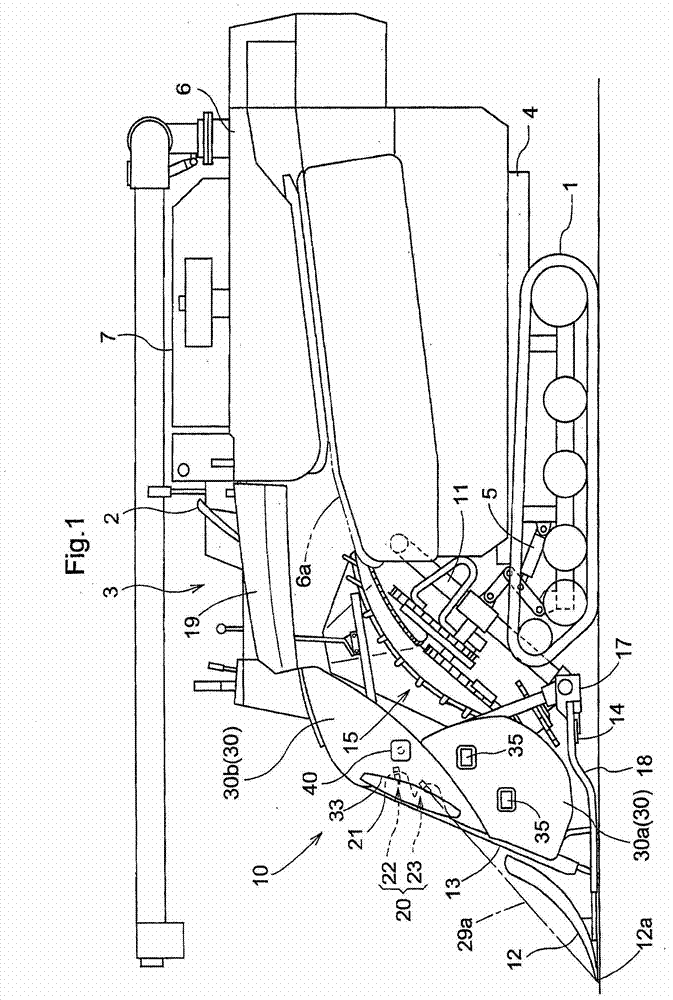

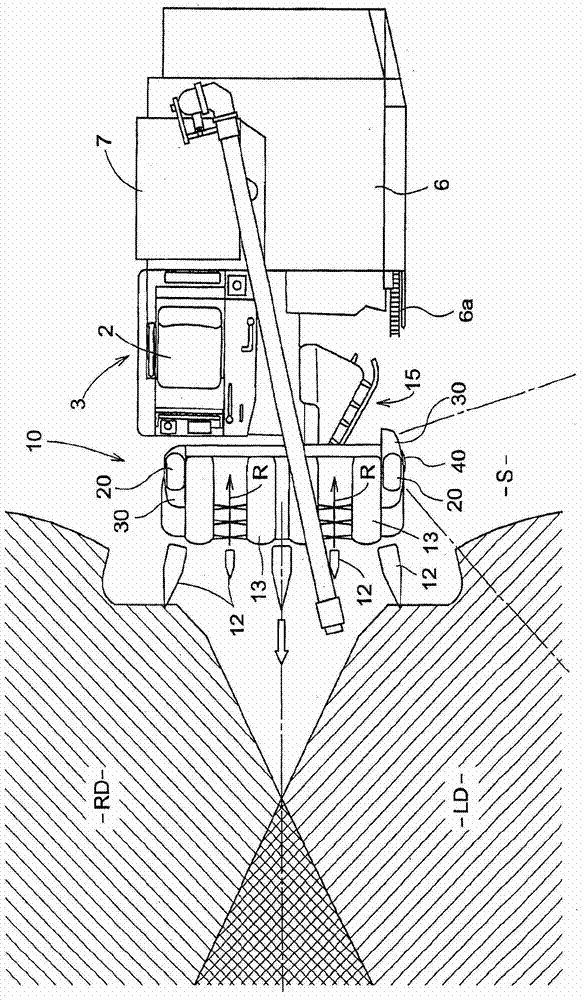

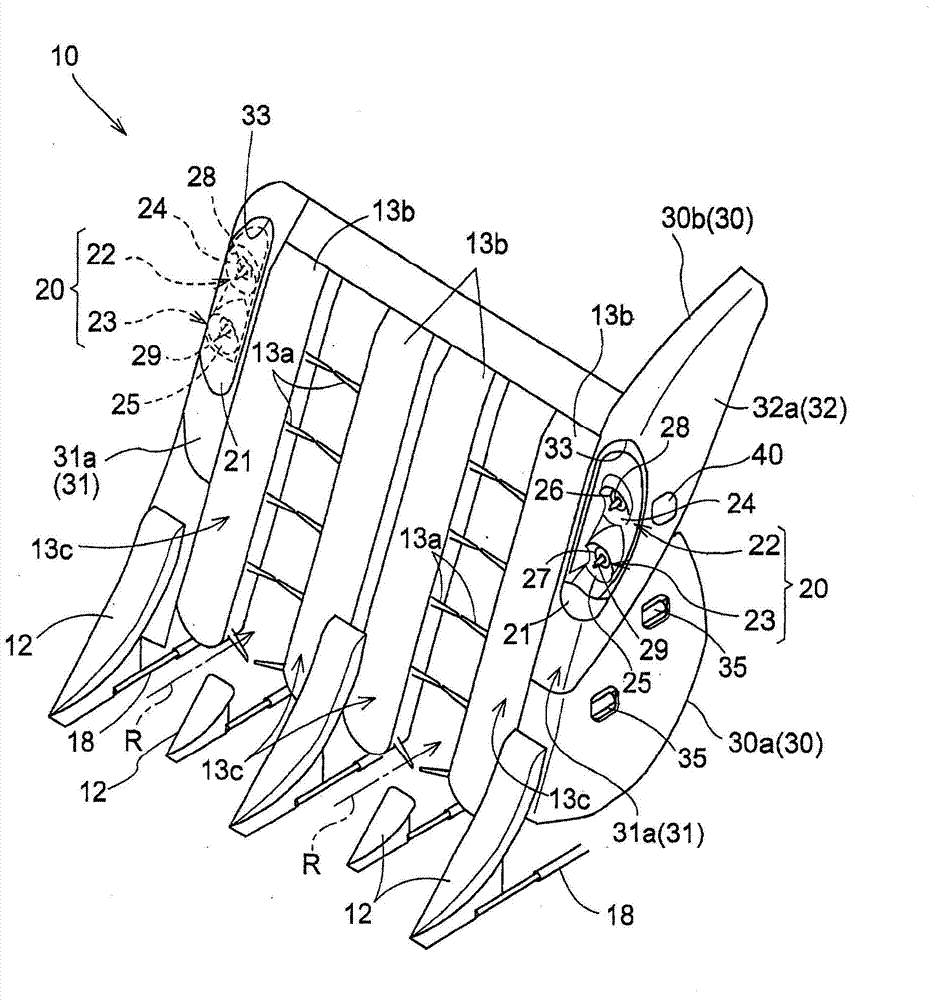

[0040] The overall composition of the combine harvester

[0041] exist figure 1 , 2 The figure shows the whole side view and the whole top view of the combine harvester which harvests rice, wheat, etc. This combine harvester is equipped with: a self-propelled body that travels with a crawler belt traveling device 1 (hereinafter simply referred to as a body), and a power unit provided at a front portion on one side of the body. The power unit includes a ride-on driving unit 3 on which a driver's seat 2 and the like are mounted, and is driven by the power of an engine (not shown) located below the driver's seat 2 . The pre-processing part frame main body 11 of the pre-harvesting processing part 10 is swingably connected to the front part of the frame 4 of a machine body around the horizontal axis P. As shown in FIG. One side of the rear portion of the frame 4 is provided with a threshing device 6 and a grain box 7 .

[0042] When the lift cylinder 5 provided at the rear l...

no. 2 Embodiment approach

[0081] Figure 15 Showing the headlight device 20 of the second embodiment of the harvester of the present invention, in the headlight device 20 , the lens 21 is provided with an upper side refractor corresponding to the bulb 28 of the upper side headlight 22 . The light projecting portion 21 a and the lower refracting light projecting portion 21 b corresponding to the bulb 29 of the lower headlight 23 .

[0082] The upper refraction light projection part 21a is provided with a refraction light projection characteristic for refraction and projection of the light from the bulb 28, so that the irradiation range of the light emitted from the bulb 28 and irradiated from the upper side refraction light projection part 21a is irradiated. , is the same as the irradiation range formed by the upper headlamp 22 provided with the above-mentioned two types of reflector portions 24a, 24b.

[0083] The lower refraction light projection part 21b is equipped with a refraction light projectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com