Stopping zipper puller

A zipper puller and stop technology, which is applied in the field of zipper products, can solve the problems of zipper puller self-locking failure, self-locking zipper puller is difficult to use, etc., and achieve the effect of a firm lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

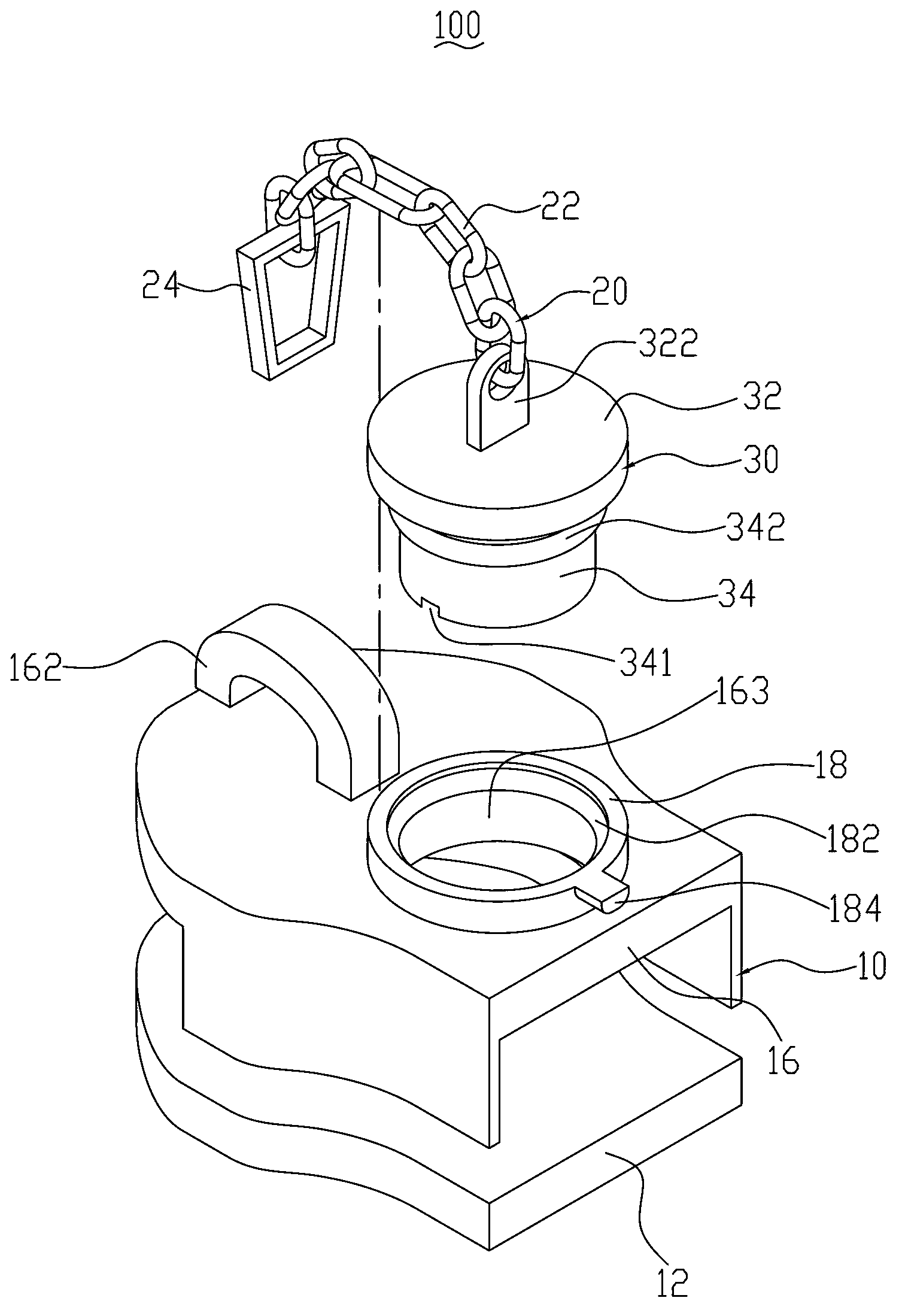

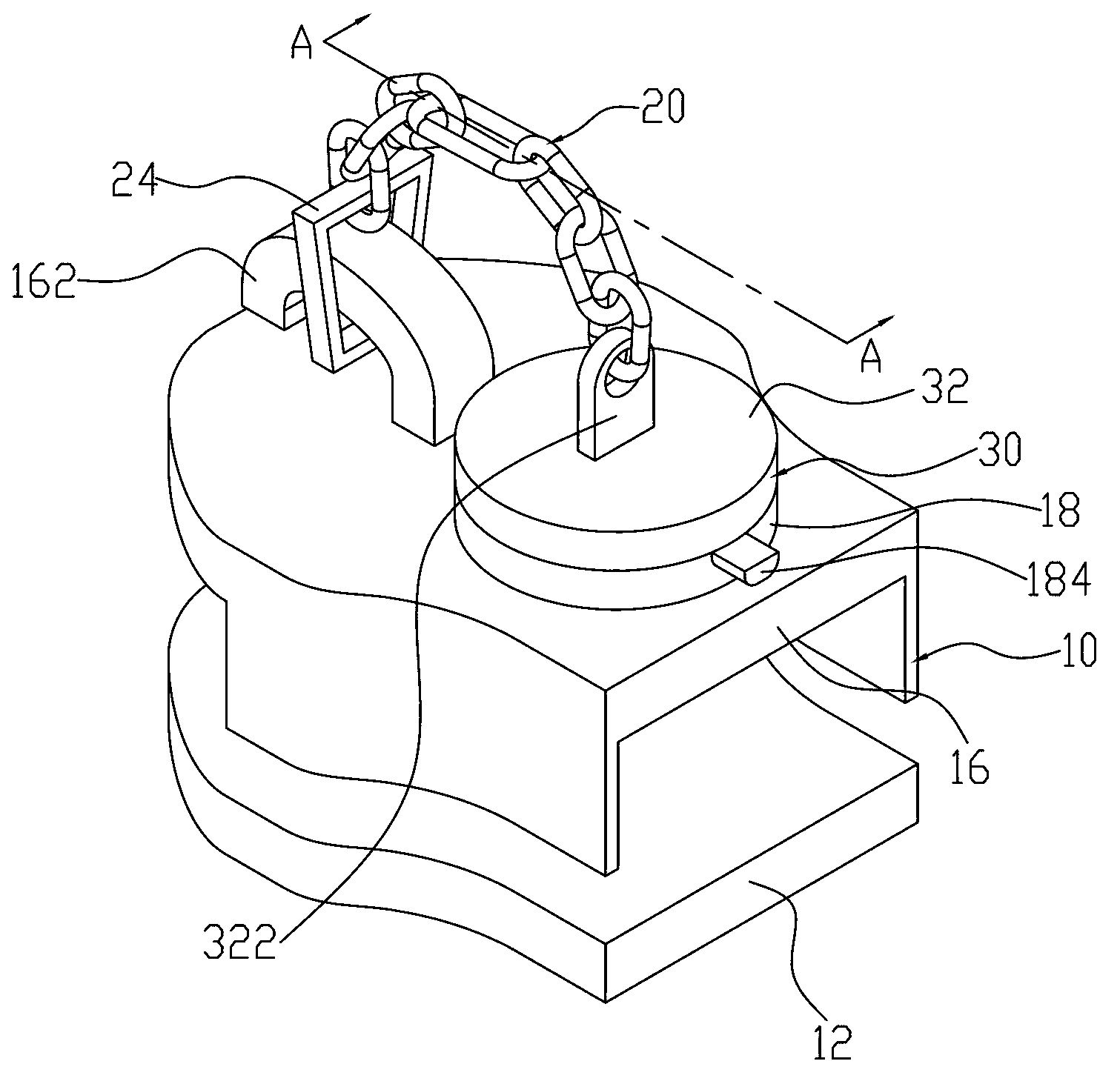

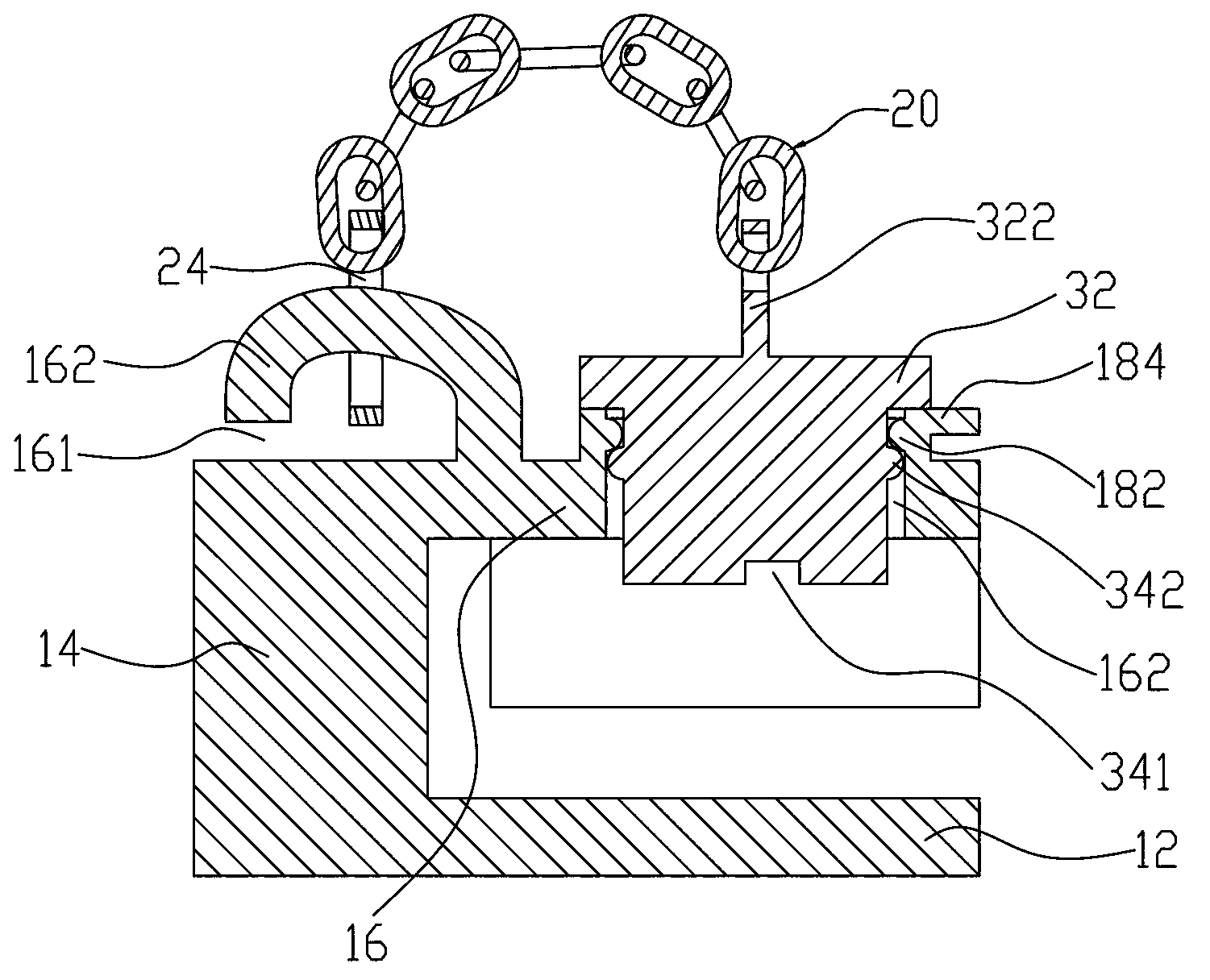

[0012] see figure 1 , The stop type zipper puller 100 of the first embodiment of the present invention includes a slider slider 10 , a handle body 20 and a stopper 30 . Both the handle body 20 and the stopper 30 are connected to the slider 10 . The stopper 30 is connected with the handle body 20 .

[0013] Please refer to Figure 1 to Figure 3 , the slider slider 10 is made of metal material, which includes a lower wing 12 , a connecting column 14 , an upper wing 16 and a limiting member 18 . The upper wing 16 , the connecting column 14 and the lower wing 12 are connected to each other to form a Y-shaped slideway for two rows of fastener elements (not shown) on the zipper belt to pass through. The limiting member 18 is disposed on the top surface of the upper wing 16 .

[0014] The upper wing 16 is provided with an elephant trunk 162 close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com