Delivery error detection device

A technology of misfeed detection and limit switch, which is applied in metal processing, metal processing equipment, safety equipment, etc., can solve the problems of reducing the service life of molds, easily breaking mold parts, and wasting time, so as to improve efficiency and improve products quality and avoid unnecessary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

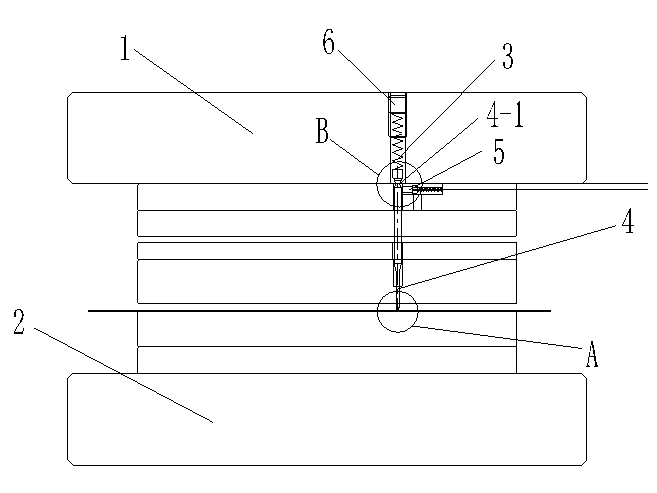

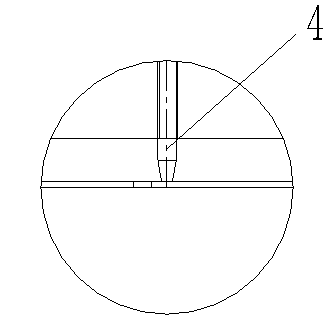

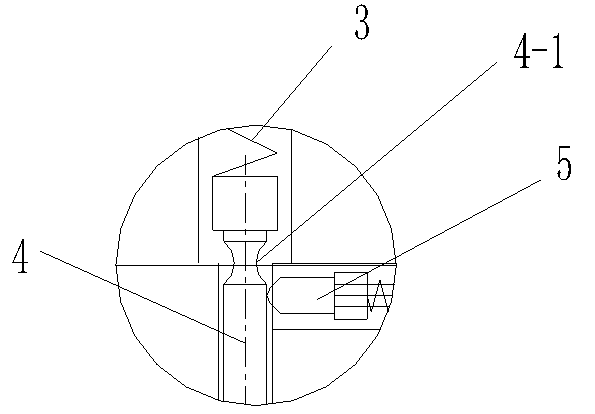

[0012] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: as Figure 1 to Figure 4 A misfeed detection device shown includes an upper die 1 and a lower die 2, the upper die 1 is connected with a wire spring 3 through a screw 6, the other end of the wire spring 3 is connected with a protection pin 4, and the protection pin 4 is provided with a groove 4 -1, one side of the protective pin 4 is provided with a limit switch 5, the limit switch 5 is nested in the groove 4-1 of the protective pin 4, the limit switch 5 is provided with a spring, which is convenient for the expansion and contraction of the limit switch.

[0013] When the material strip is transported to the predetermined position, the upper die punches down, and the protection needle matches the hole on the material strip, and the protection needle completes the stamping of the material strip; when the material strip is not transported to the predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com