Core box loose piece automatic mold release device

An automatic demoulding and loose block technology, applied in the direction of casting molding equipment, etc., can solve the problems of unfavorable sand core quality stability and improvement, failure to meet mass production, and affect production efficiency, etc., to achieve mechanized mass production and stable quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

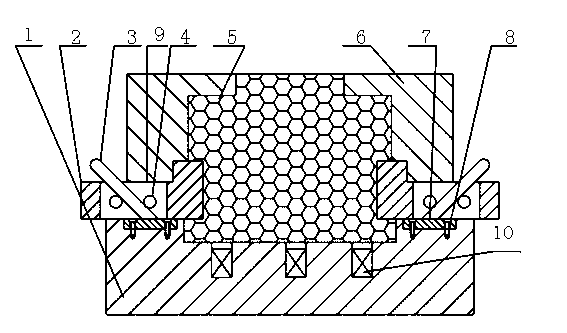

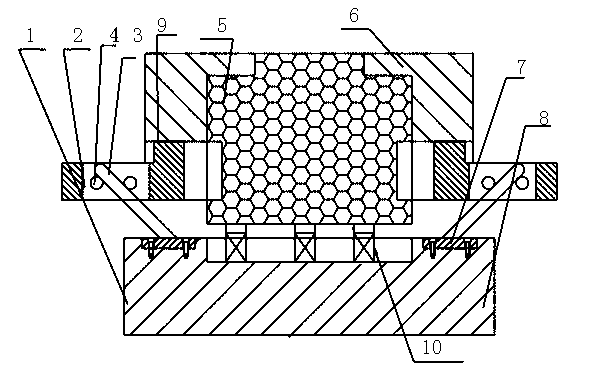

[0013] The present invention as figure 2 , image 3 shown.

[0014] In the present invention, a movable block 2 is provided between the static core box 1 and the movable core box 6, and a pair of rollers 4 are respectively provided on the sides of the movable block 2, which are combined into a movable block assembly, and the movable block assembly is embedded through the guide rail 9 In the moving core box 6, a slider guide rod 3 is provided from the middle of the roller 4, the slider guide rod 3 is obliquely fixed on the guide rod fixing plate 7, and the guide rod fixing plate 7 is fixed on the static core box 1 by bolts 8; An automatic core ejector device 10 is provided inside the bottom of the static core box 1 .

[0015] The slide block guide rod 3 is fixed on the guide rod fixed plate 7 and the inclination angle is 40~70 °, wherein the guide angle of 45 ° is more conducive to demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com