Reversible multi-station vacuum-suction bench

A multi-station, positive and negative technology, applied in the direction of manufacturing tools, metal processing equipment, workpiece clamping device, etc., can solve the problem that the processed product cannot be positioned and fixed by mechanical means, and achieves convenient control, simple control mode, Guarantee the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

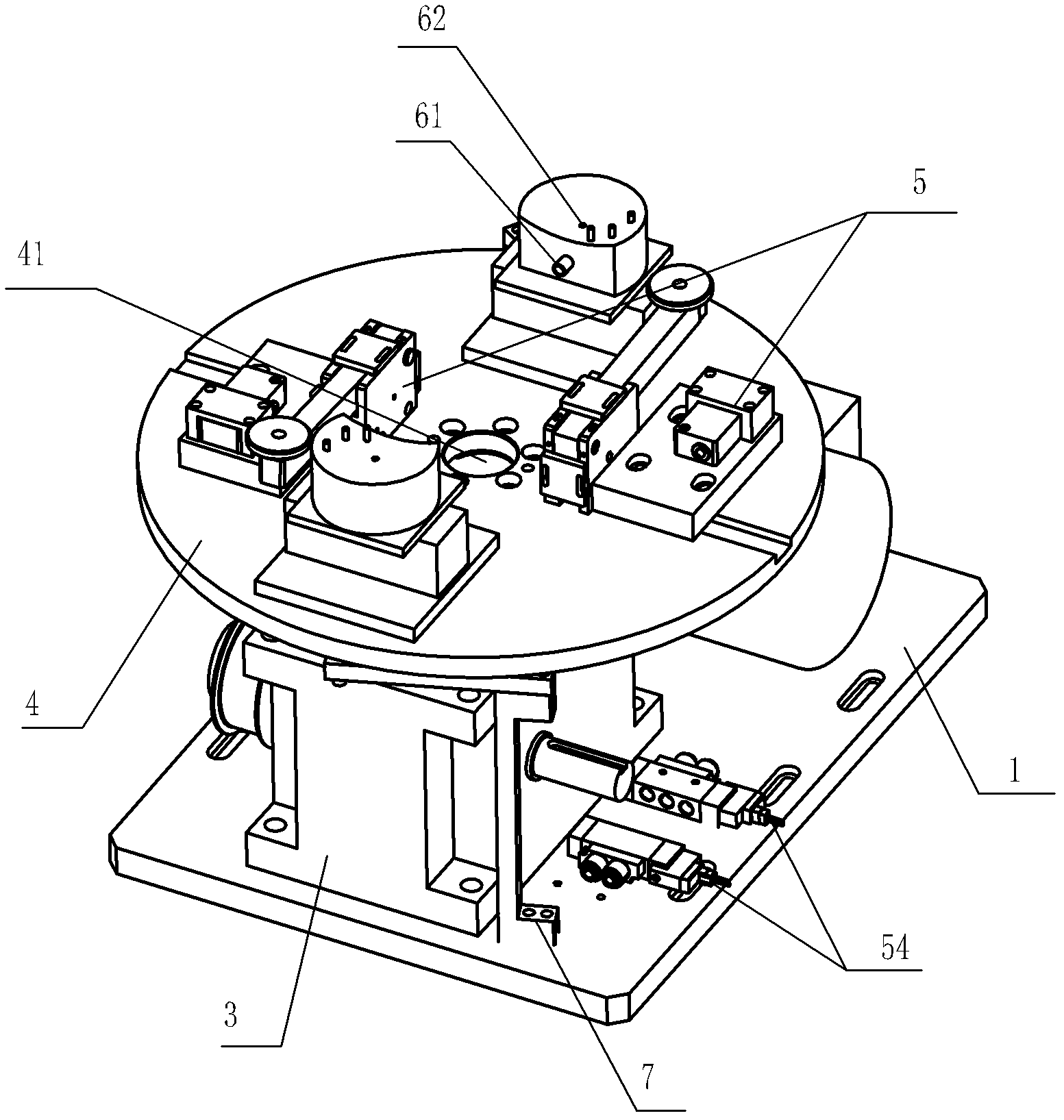

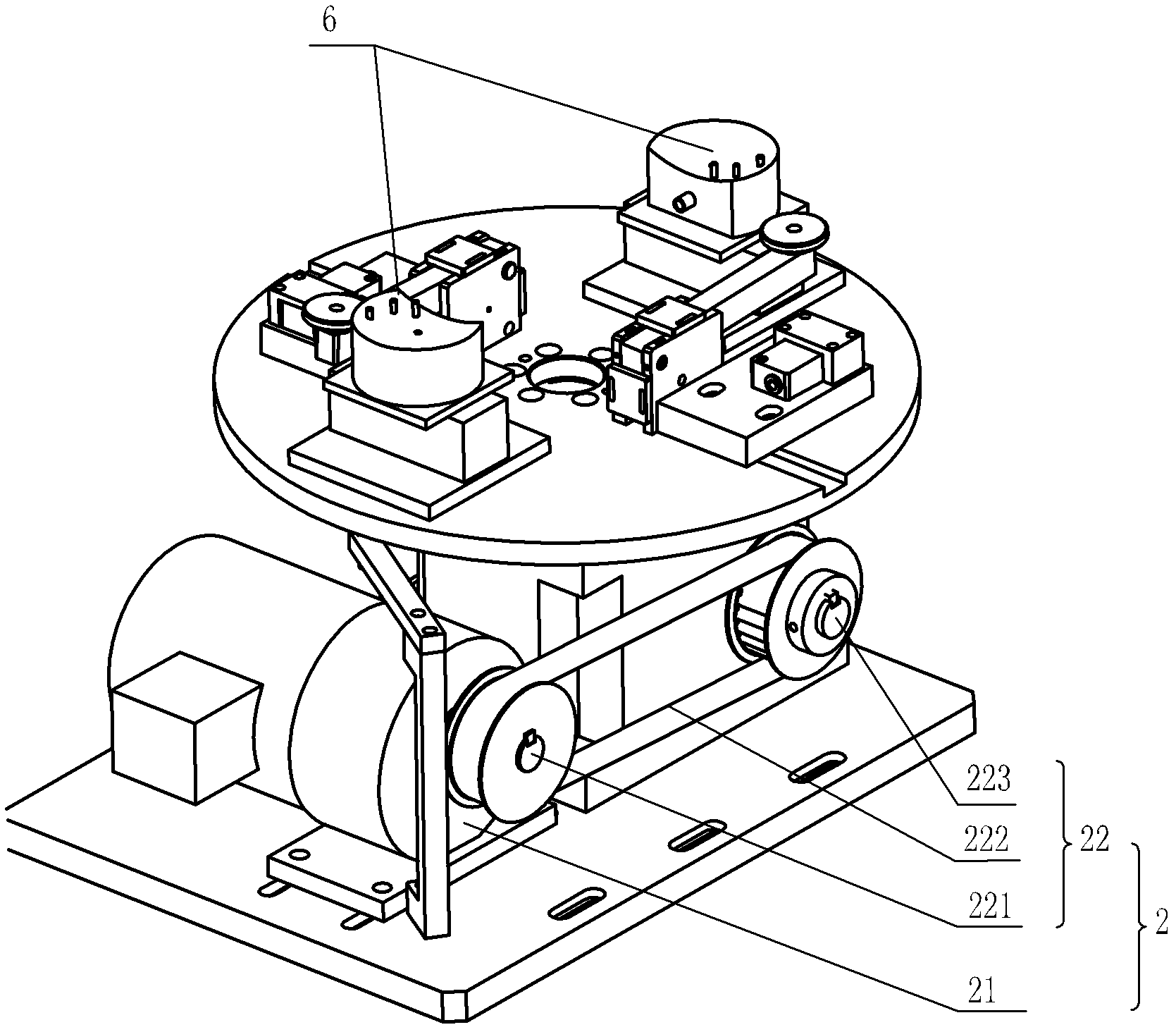

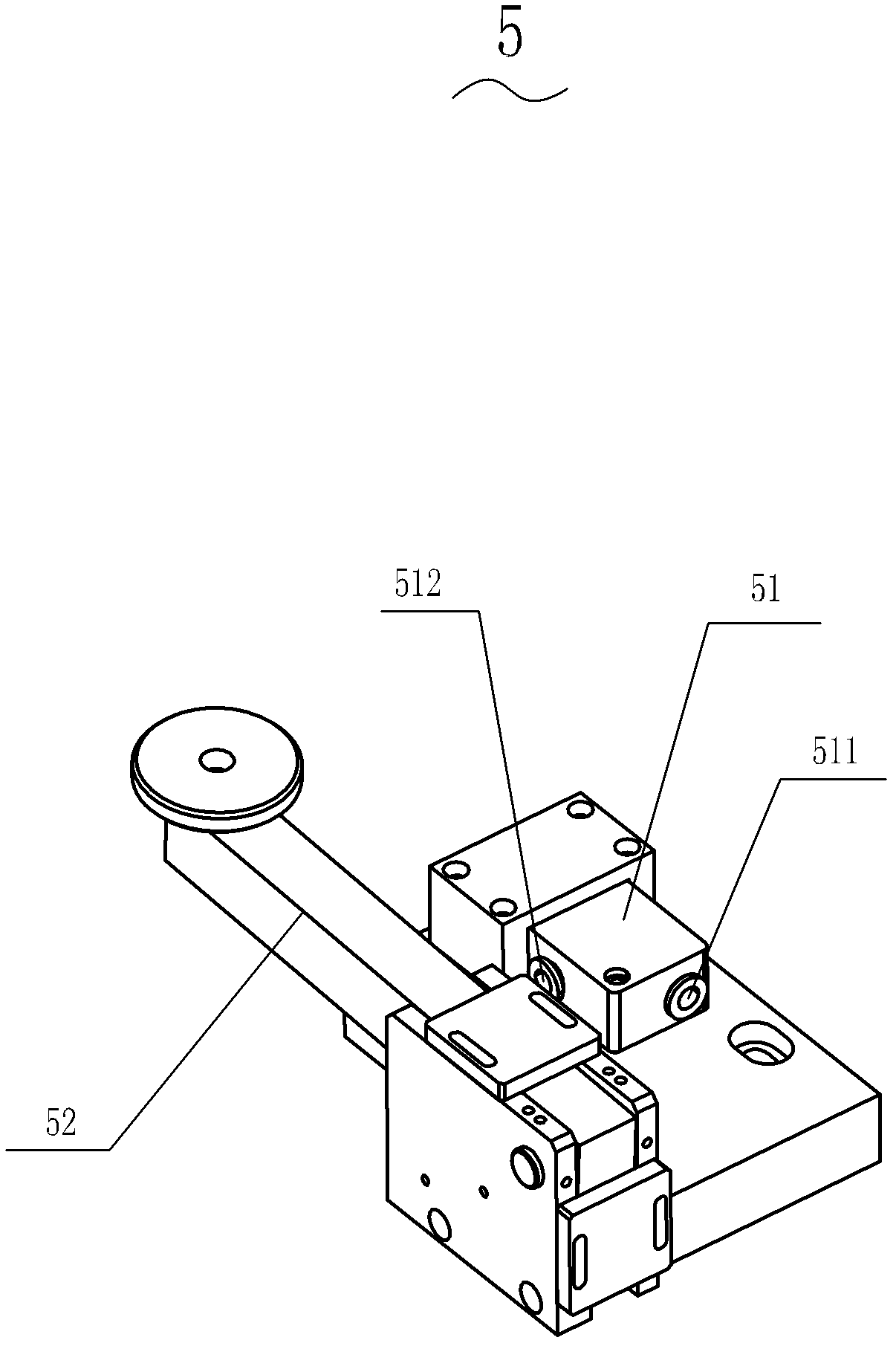

[0011] In order to express the purpose, technical solution and advantages of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments and drawings described here are only used to understand the present invention, and are not used to limit the protection scope of the present invention.

[0012] The invention provides a forward and reverse multi-station negative pressure adsorption workbench, which includes a base plate, a power device and a divider fixed on the same base plate, a turntable installed on the divider, and each station installed on the turntable There are at least two stations on the turntable, and the divider is driven by a power device.

[0013] The negative pressure adsorption fixture of the present invention absorbs workpieces to be processed. Since the number of stations is equiangularly distributed, the rotation of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com