Automobile wheel casing fender structure

A technology for fenders and automobile wheels, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of increased wheel rotation resistance, looseness and falling off, poor heat dissipation effect of wheels, etc., and achieves the goal of improving the heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

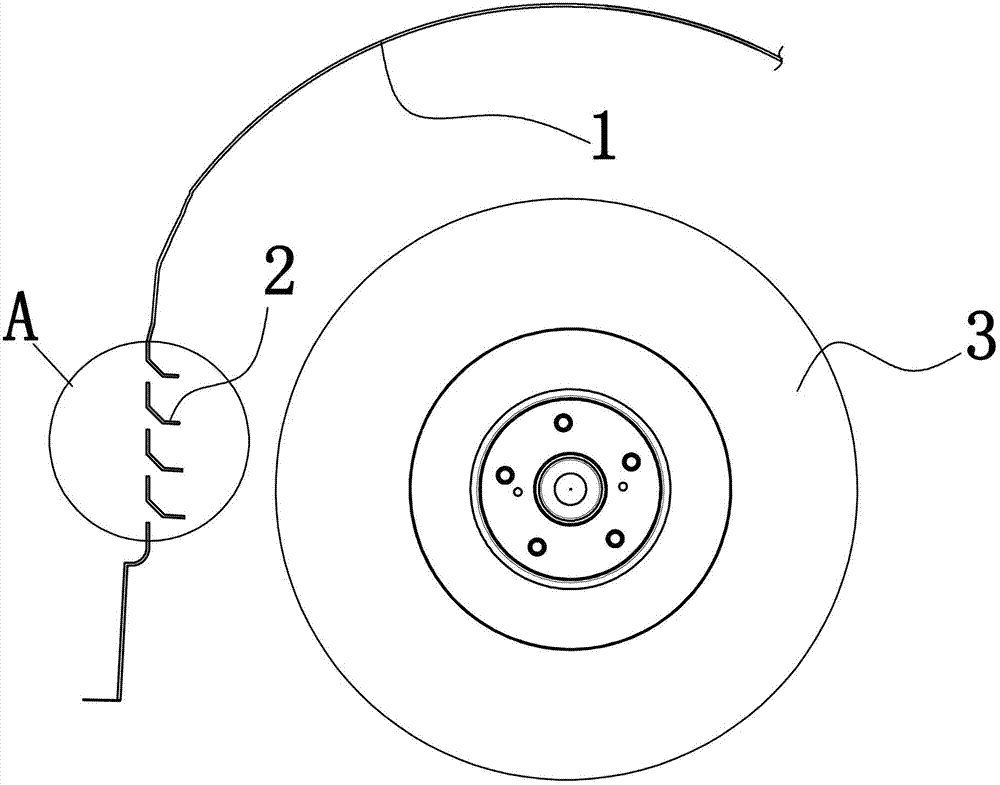

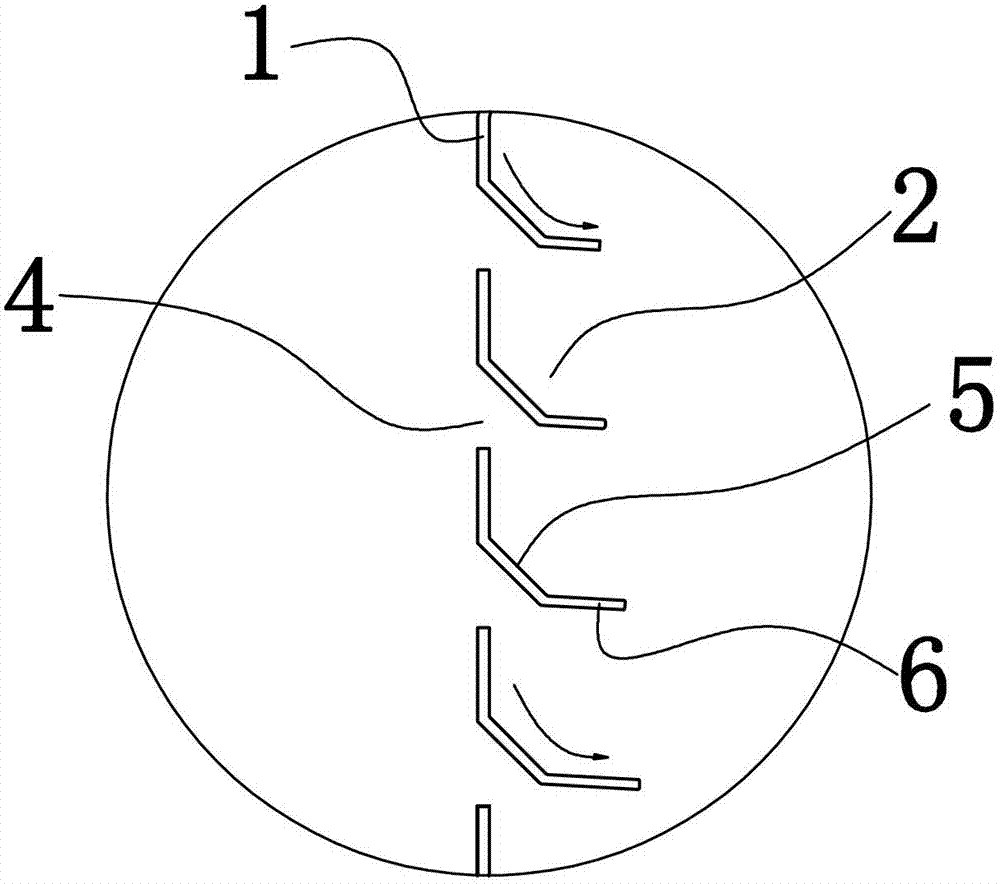

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a car wheel cover fender structure, the fender 1 is provided with a number of heat dissipation holes 4 on the front side of the wheel 3, and the upper edge of the heat dissipation holes is provided with a wind deflector 2 extending obliquely downward. The heat dissipation holes 4 are strip-shaped and extend from the outer side of the fender 1 to the inner side, and the heat dissipation holes 4 are evenly distributed from top to bottom. The wind deflector 2 also extends from the outer side of the fender to the inner side opposite to the cooling holes. Such as figure 2 As shown, the wind deflector 2 extends outward from the root of the wind deflector and includes an inclined portion 5 close to the root of the wind deflector and a guide portion 6 perpendicular to the fender. The length of each wind deflector 2 extending from the root to the outside gradually increases from top to bottom.

[0021] Since there ...

Embodiment 2

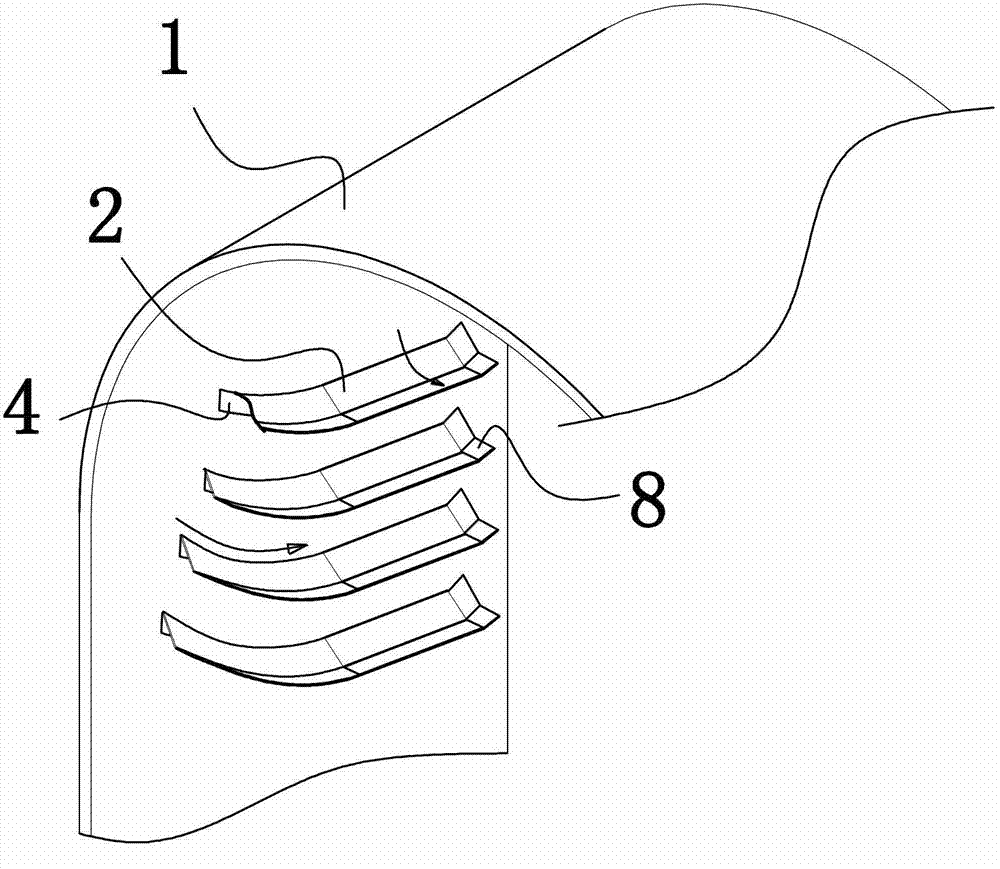

[0025] Embodiment 2: as figure 1 , figure 2 , Figure 4 As shown, the fender 1 is provided with a number of heat dissipation holes 4 on the front side of the wheel 3, and the upper edge of the heat dissipation holes is provided with a wind deflector extending obliquely downward. The cooling holes 4 are strip-shaped and extend horizontally from the outer side of the fender to the inner side, and the cooling holes are evenly distributed from top to bottom. The wind deflector 2 also extends horizontally from the outer side of the fender to the inner side opposite to the cooling holes. Such as figure 2 As shown, the wind deflector 2 extends outward from the root of the wind deflector and includes an inclined portion 5 close to the root of the wind deflector and a guide portion 6 perpendicular to the fender. The length of each wind deflector 2 extending from the root to the outside gradually increases from top to bottom.

[0026] Such as Figure 4 As shown, the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com