Lifting device of aluminum electrolytic cell

A technology of aluminum electrolytic cells and lifting devices, which is applied in the field of lifting devices, can solve the problems of affecting production progress, time-consuming and laborious, and low frequency of crane use, and achieves the effects of low cost, convenient use, and overcoming production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

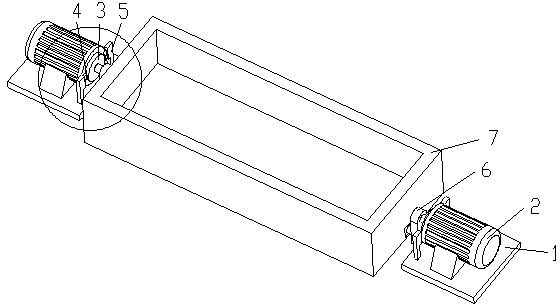

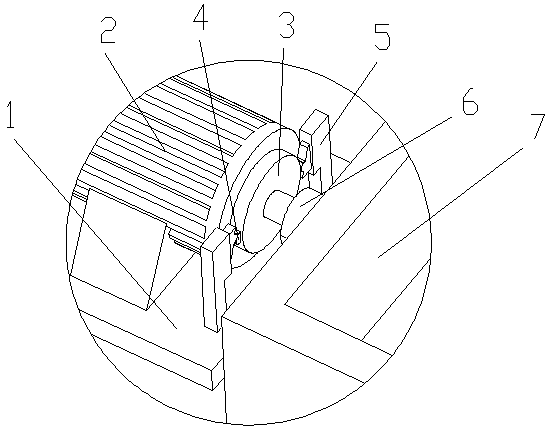

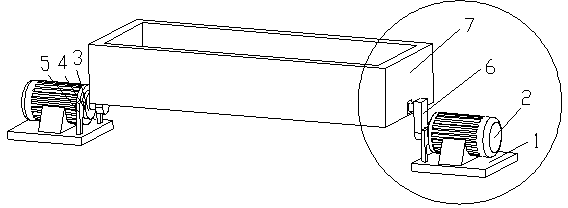

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached Figure 1-4 The shown lifting device for an aluminum electrolytic cell according to the present invention includes a base 1, a motor 2, a turntable 3, a bump 4, an electromagnetic switch 5, a crank 6, and an aluminum electrolytic cell 7; the motor 2 is arranged on On the base 1; the output shaft of the motor 2 is provided with a turntable 3; the bump 4 is arranged on the outer circumference of the turntable 3; the electromagnetic switch 5 is provided with a group, which are respectively arranged on both sides of the turntable 3; The bump 4 can touch the electromagnetic switch 5 when the turntable 3 rotates; the output shaft of the motor 2 is connected with a crank 6;

[0015] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0016] The lifting device of the aluminum ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com