Excavator oil consumption display control system, control method thereof, and excavator

A display control and excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high cost, customers' inability to complete fuel consumption test independently, and inability to test instantaneous fuel consumption, etc., and achieve the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

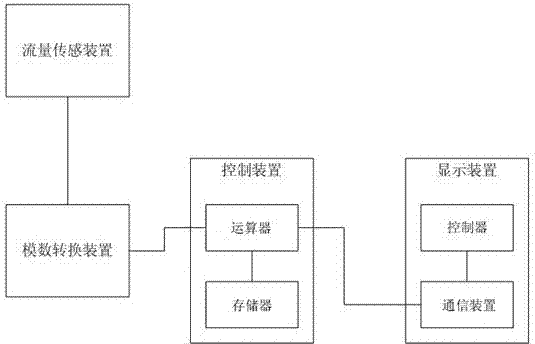

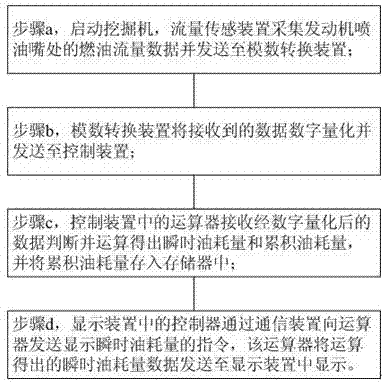

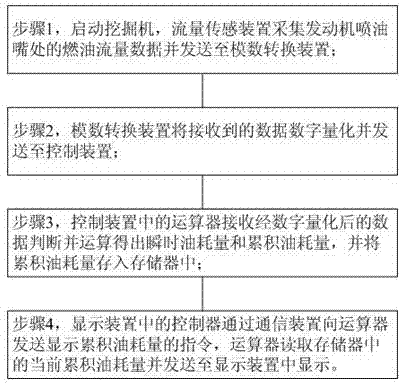

[0043] like figure 1 Shown is an excavator fuel consumption display control device, including a flow sensing device, an analog-to-digital conversion device, a control device and a display device. The flow sensing device is installed at the fuel injector of the engine and connected to the analog-to-digital conversion device; The analog-to-digital conversion device is connected to the control device through the CAN bus; the control device is connected to the display device through the CAN bus; the flow sensor device can also be a professional fuel flow meter.

[0044] The flow sensor device is used to monitor and collect the fuel flow data passing through the fuel injector of the engine and send it to the analog-to-digital conversion device; the analog-to-digital conversion device digitizes the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com