Composite material combined type cross arm for high-tension transmission line tower pole

A technology for high-voltage transmission lines and composite materials, which is applied in towers, building types, buildings, etc., can solve the problems of not fully exerting the performance advantages of composite materials, large welding volume, expensive welding materials and man-hours, etc., and achieves a fast and simple assembly method. , The effect of reducing the occupied ground surface and improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

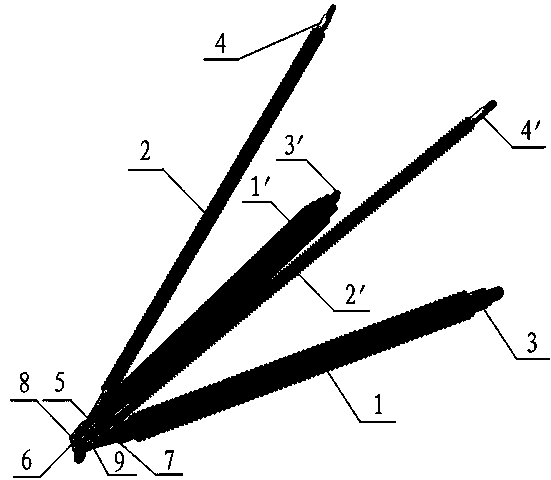

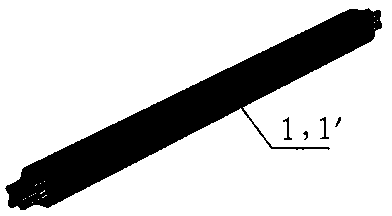

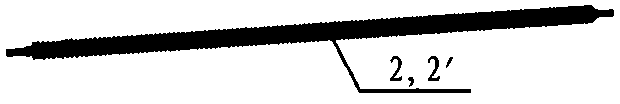

[0026] Such as figure 1 As shown, the composite material combined cross arm of the high-voltage transmission line tower of the present invention includes 2 bending-resistant composite insulating parts 1, 1' and 2 tensile composite insulating parts 2, 2'; the end of each composite insulating part Parts are equipped with end fittings 6, end fittings 7, end fittings 8, and end fittings 9; end fitting connecting plates 5 that assemble the end fittings of 4 composite insulating parts into one; each composite insulating part The roots are assembled with root fittings 3, 3' and root fittings 4, 4'; among them, the bending-resistant composite insulation parts 1, 1' are bonded and fixed to the end fittings 6 and 7 respectively, and the bonding The epoxy adhesive used is produced by Hexion Specialty Chemical Company, the model is 135G3T-M16a epoxy adhesive; the tensile composite insulating parts 2, 2' and the end fittings 8 and end fittings 9 are respectively coaxial The press is crimp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com