Continuous and changeable valve lift control mechanism

A valve lift, control mechanism technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unfavorable engine layout, increasing engine height, and inability to change valve lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

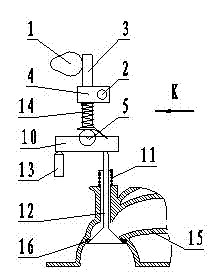

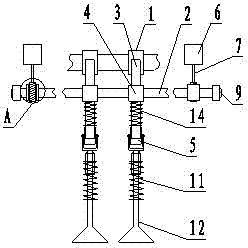

[0025] Referring to Fig. 1 and Fig. 2, the present invention includes a transmission assembly and a valve assembly, and the transmission assembly includes a cam 1, a rocker shaft 2, a rocker 3, a rocker support block 4, a rocker roller 5, a rocker 10 and a hydraulic lifter The column 13 is special in that: the rocker shaft 2 can move up and down driven by the height adjustment motor 6, and the height adjustment motor 6 is fixedly installed on the engine cylinder head 15.

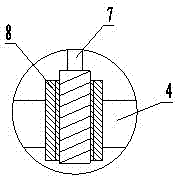

[0026] See Figure 1, figure 2 , image 3 , the rocker shaft 2 of the present invention is connected with the height adjustment motor 6 through a screw nut transmission mechanism, the screw nut transmission mechanism is composed of a height adjustment screw 7 and a height adjustment nut 8, and the height adjustment screw 7 is fixedly mounted on the height adjustment motor 6 on the output shaft, the height adjustment nut 8 is fixed on the rocker shaft 2, and the rocker shaft slider 9 fitted with the slideway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com