Camshaft assembly of engine with variable valve opening duration

A technology of opening duration and camshaft, applied in engine components, engine control, combustion engine, etc., can solve problems such as difficulty in fully engine power and economy, and long valve opening duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

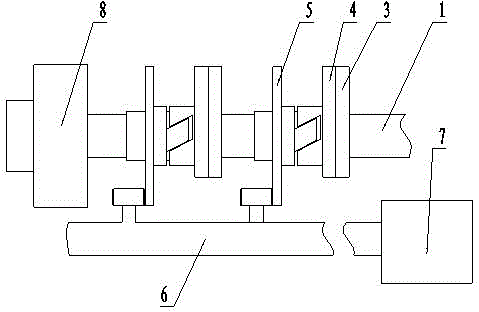

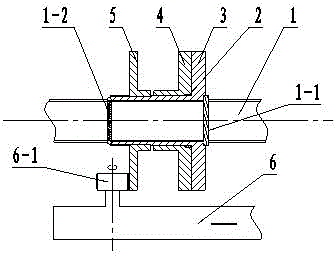

[0027] Referring to Fig. 1 and Fig. 2, the present invention includes a group of valve opening duration control units whose number matches the number of engine cylinders, a camshaft 1 and a variable valve timing control mechanism 8, and the valve opening duration control unit is connected with the camshaft 1, the camshaft 1 is a spline shaft, and the variable valve phase control mechanism 8 is assembled on the input end of the camshaft 1.

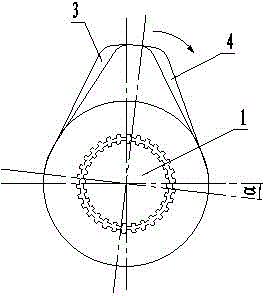

[0028] see Figure 3 ~ Figure 12 , the valve opening duration control unit of the present invention includes a sleeve cam A 3, a sleeve cam B 4, an angle control sleeve 5, an actuator 6 and a controller 7, and the sleeve cam A 3 is provided with a cam at one end. The sleeve structure has a spline tooth 3-1 on the outer wall of the other end, a spline tooth groove Ⅰ 3-2 on the inner wall, and a positioning pin on the cam end of the inner wall of the sleeve cam A. Slot 3-3, the other end is provided with locking groove 3-4, and the sleeve ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com