A Checking Tool Used for Dimensional Inspection of Knuckle Arm

A dimensional inspection and inspection tool technology, which can be used in mechanical clearance measurement, angle/taper measurement, etc., and can solve the problems of large measurement error, large workload, and disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

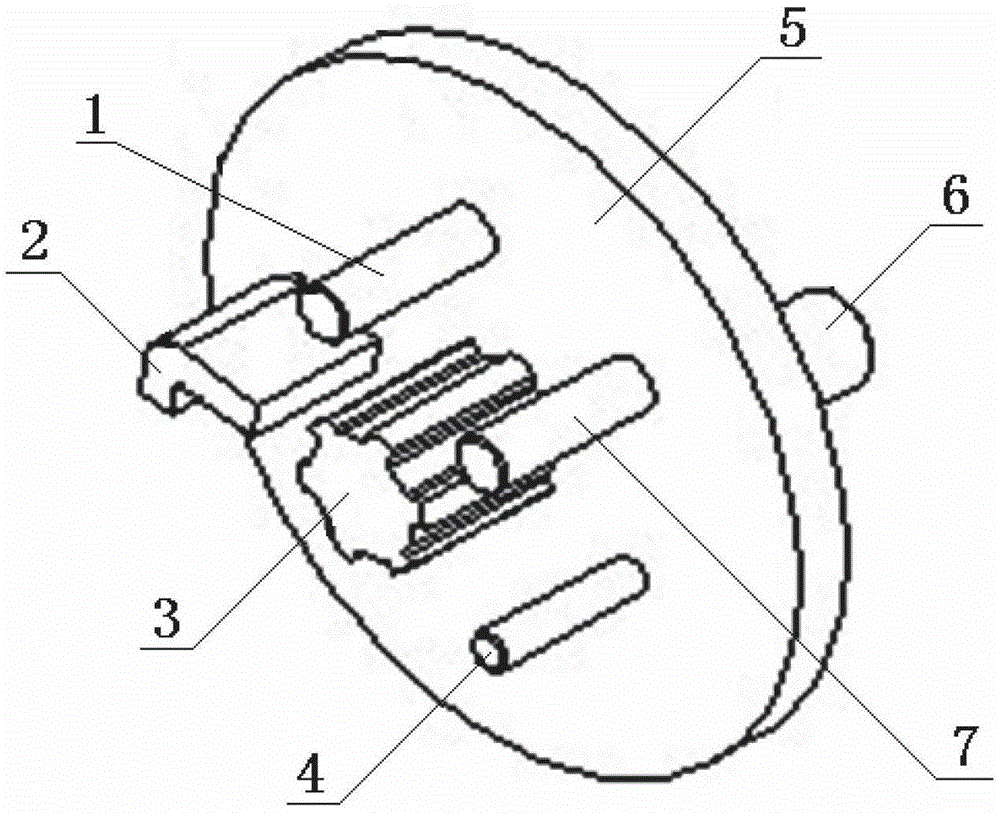

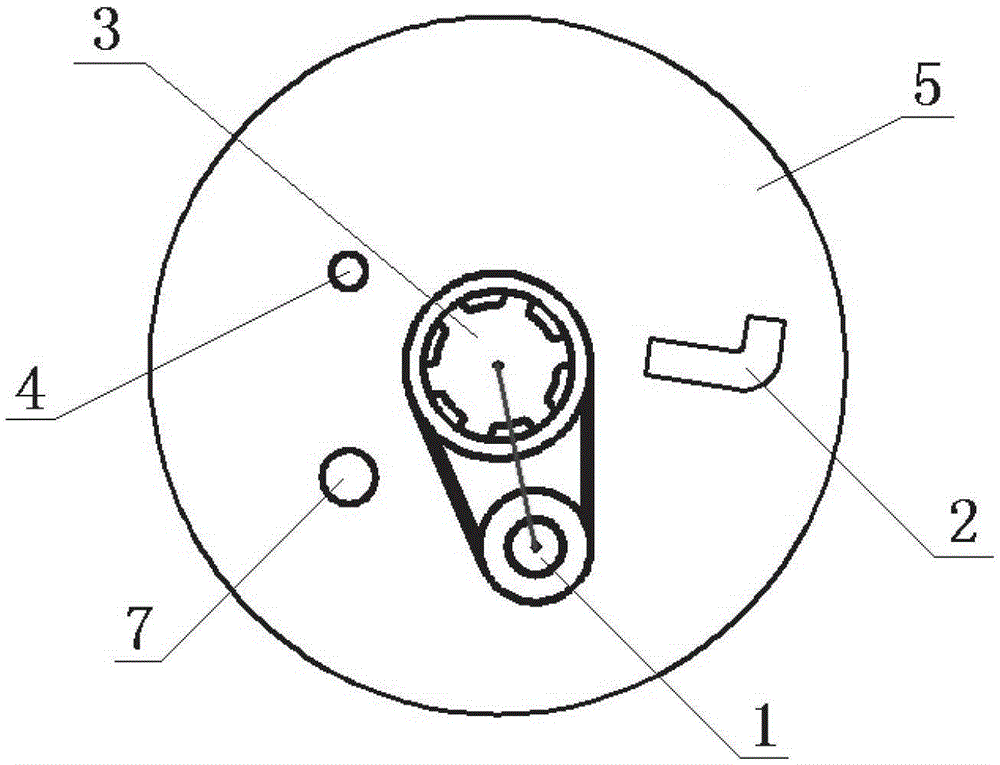

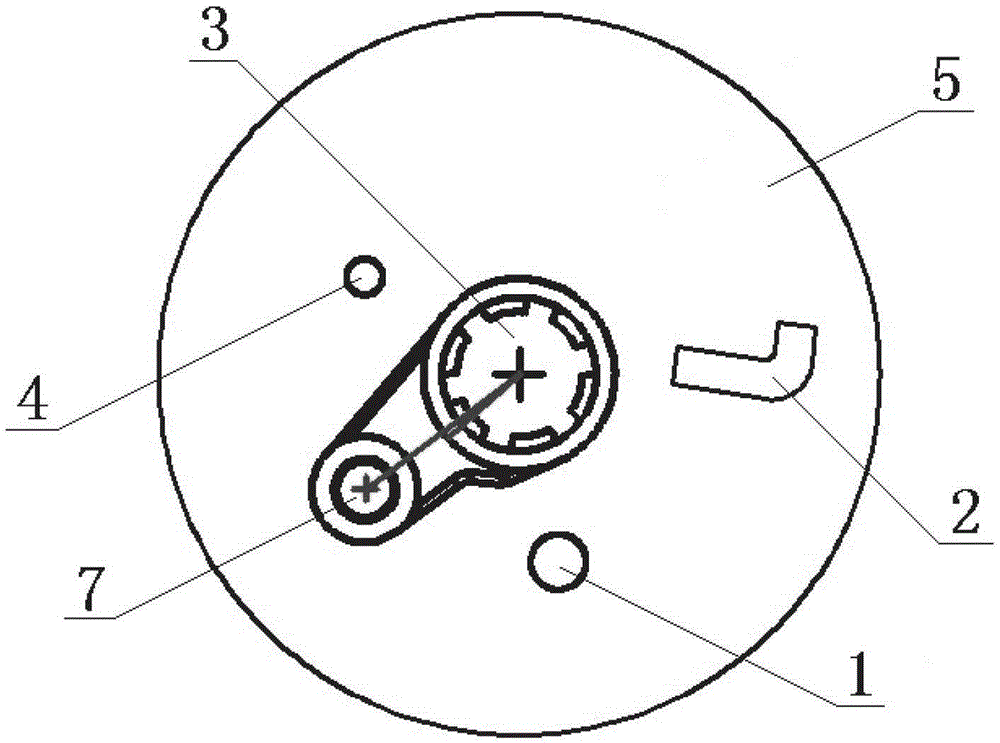

[0015] Depend on figure 1 Combining the shown structures, it can be seen that this kind of inspection tool for the inspection of the crank arm size includes a disc-shaped or square base 5 and a base nut 6 supporting the base 5. The base 5 is provided with at least A cylindrical pin, block 2 and spline shaft 3, the distance between the cylindrical pin, block 2, and spline shaft 3 is determined according to the size of the crank arm to be tested.

[0016] There are three cylindrical pins, namely the first cylindrical pin 1, the second cylindrical pin 4 and the third cylindrical pin 7, and the diameters of the first cylindrical pin 1 and the second cylindrical pin 4 are different, and the first cylindrical pin 1 and the third cylindrical pin The pins 7 have the same diameter.

[0017] When the workpiece is inspected, the axis center of the spline shaft 3 is positioned, and the deviation of the center distance from the axis center of the spline shaft 3 to the first cylindrical pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com