Method and apparatus for steel structure metal profiled sheet roof suction performance field detection

A technology of metal profiling and on-site inspection, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve problems such as roof lifting, damage, and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

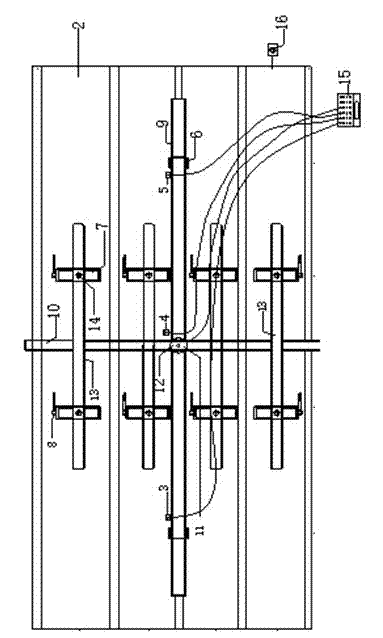

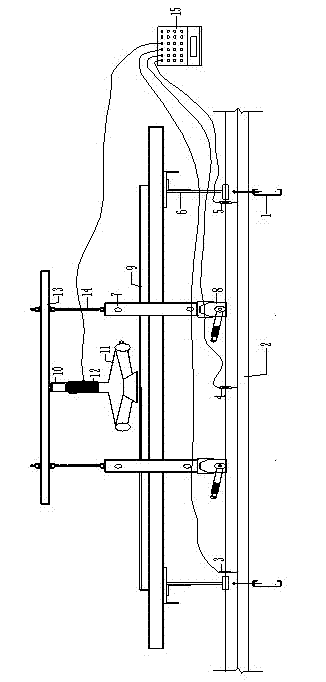

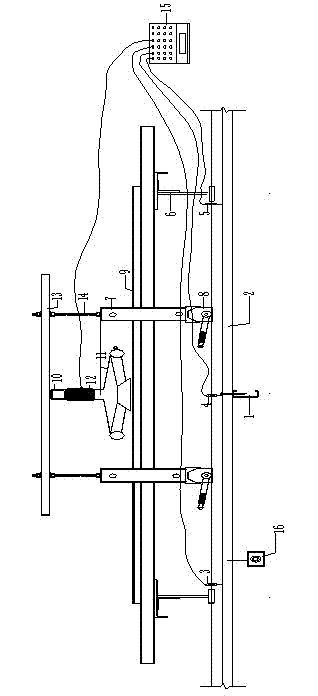

[0030] Such as figure 1 , 2 Shown in and 3: a device for on-site detection of the suction performance of a steel structure metal profiled plate roof, including a main distribution beam 9, a primary distribution beam 10, a secondary distribution beam 13, a pressure support 6, a pull support 7, a magnetic adsorption device 8, adjusting screw 14, jack 11, sensor 12, first displacement meter 3, second displacement meter 4, third displacement meter 5, strain gauge 15 and digital camera 16, the lower parts of the two ends of the main distribution beam 9 adopt The clamp is connected with two pressure bearings 6, the jack 11 rests on the middle position of the main distribution beam 9, the sensor 12 is arranged on the jack 11 and is in tight contact with the primary distribution beam 10 through a nut, the primary The distribution beam 10 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com