a reactor

A technology for reactors and casings, which is applied in the direction of inductors, fixed inductors, transformers/inductor casings, etc., can solve the problems that reactor heat cannot be quickly absorbed, affects performance and use, and damages coils, etc., to avoid a sharp rise in temperature High, prolong service life, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0017] A reactor has a shell, a coil and a magnetic material are contained inside the shell to form a reactance unit 4, and an insulating and thermally conductive filler is provided between the magnetic material wound with the coil and the inner wall of the shell, and the filler is metal oxide powder Mixed with epoxy resin, oxidized metal powder is evenly distributed in epoxy resin. Considering the production cost, in this embodiment, the metal oxide powder is preferably processed alumina powder, and the volume percentage of the metal oxide powder and the epoxy resin is 5:5.

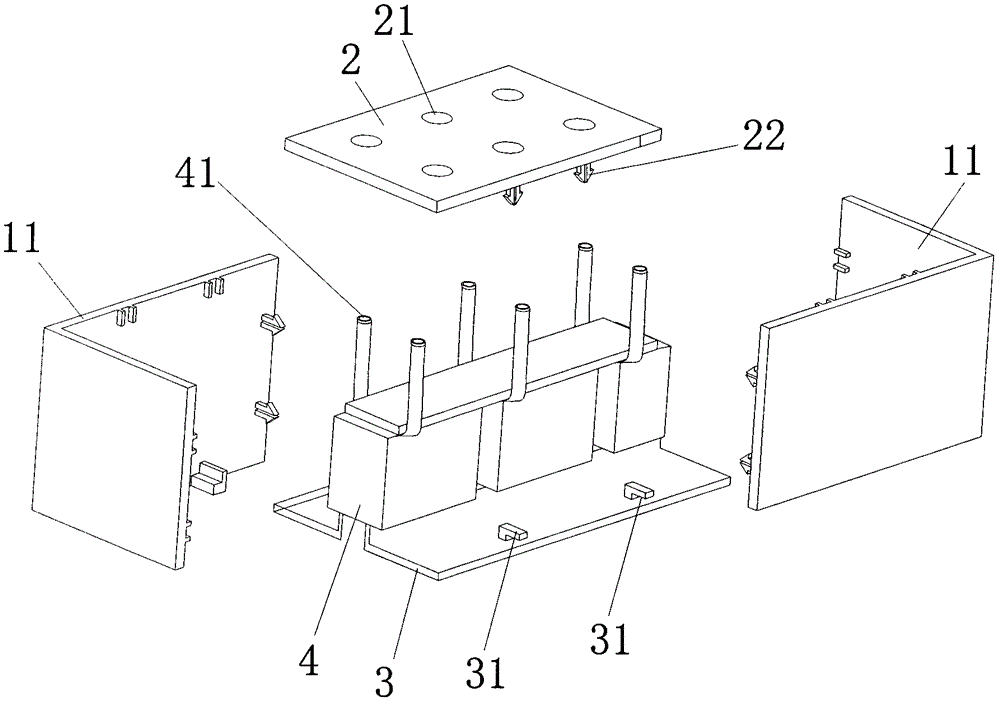

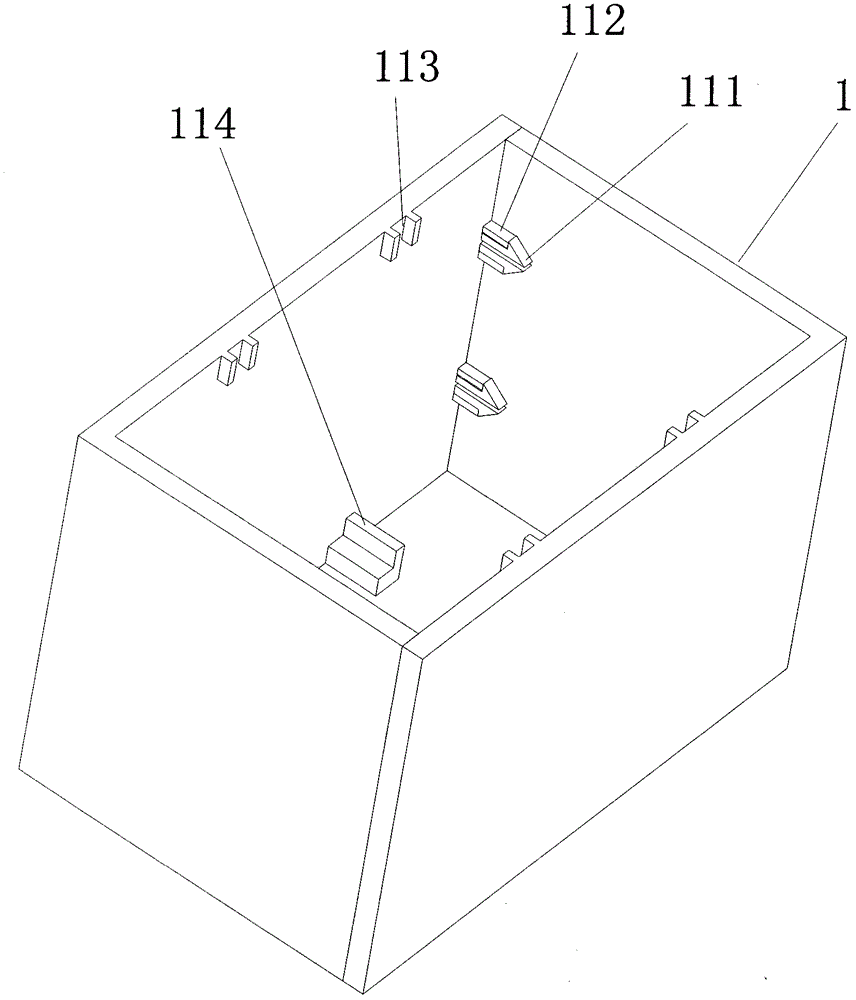

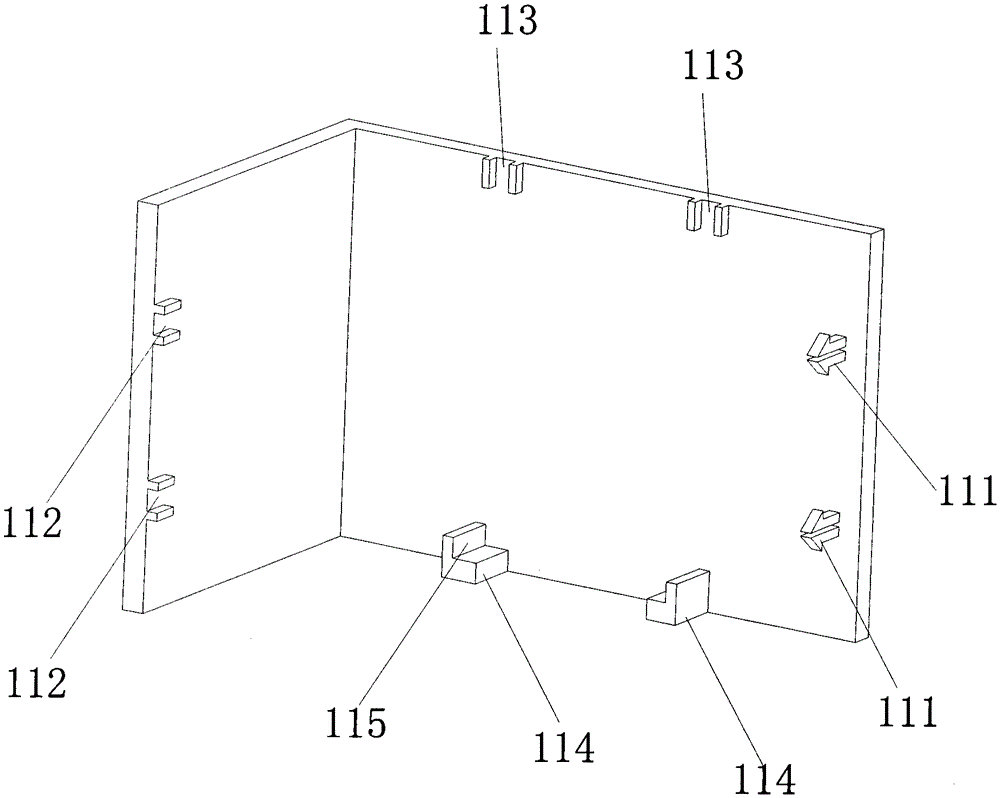

[0018] Such as figure 1 , figure 2 with image 3 As shown, the housing is composed of a plastic side plate 1 and a top plate 2. The side plate 1 includes two right-angled folded plates 11, and the end and end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com