Bumper structure

一种保险杠、保险杠加强件的技术,应用在保险杠、车辆部件、车辆安全安排等方向,能够解决增加竖直重叠量、增加组装时间、增加部件数量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

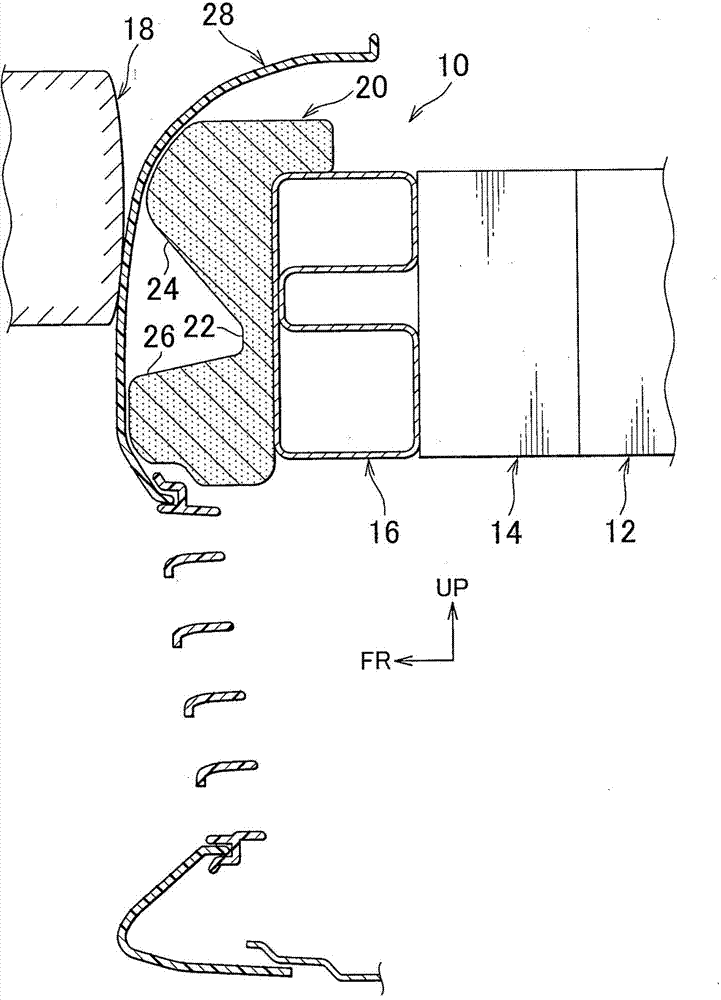

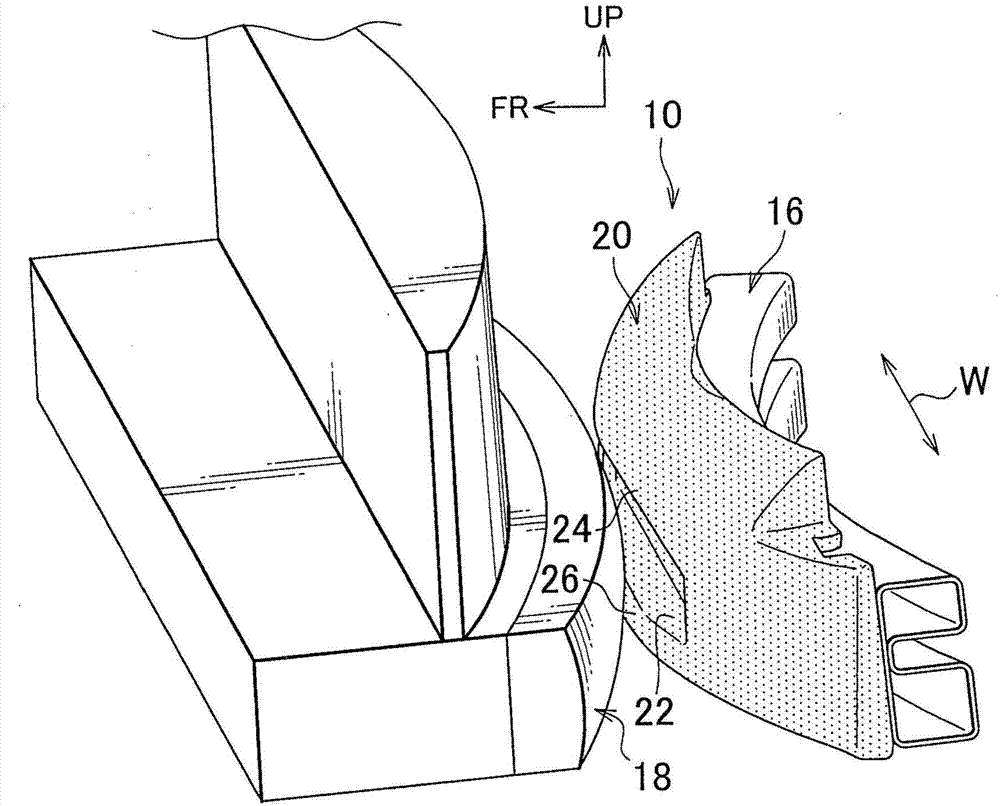

[0048] Next, a bumper structure according to a first embodiment of the present invention will be described with reference to the drawings. The first embodiment will be described based on an example in which a bumper structure of one aspect of the present invention is incorporated in a front bumper of a vehicle relatively small in height such as a racing car. Note that, in the drawings, an arrow "FR" indicates a direction toward the front side of the vehicle, an arrow "UP" indicates a direction toward the upper side of the vehicle, and an arrow "W" indicates a lateral direction of the vehicle.

[0049] like figure 1 As shown, the bumper structure 10 of the first embodiment includes a pair of front side members 12 provided at respective lateral sides of the vehicle and extending in the longitudinal direction of the vehicle, and a bumper reinforcement 16 extending in the lateral direction of the vehicle is attached. The crash box 14 is interposed between the bumper reinforcement...

no. 2 example

[0075] Next, we will refer to Figure 5 A bumper structure according to a second embodiment of the present invention is described. Note that the same elements as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof will be omitted. The second embodiment is an example of incorporating a bumper structure of one aspect of the present invention in a rear bumper of a vehicle relatively small in height such as a racing car.

[0076] like Figure 5 As shown, in the bumper structure 10 of the second embodiment, reference numeral 128 denotes a rear bumper cover, and reference numeral 116 denotes a rear bumper reinforcement, and the bumper absorber 20 is attached to the rear bumper reinforcement 116 on the rear side of the vehicle.

[0077] The bumper structure 10 of the second embodiment applied to the rear bumper is basically the same as the bumper structure 10 of the first embodiment applied to the front bumper. The shape of the bumpe...

no. 3 example

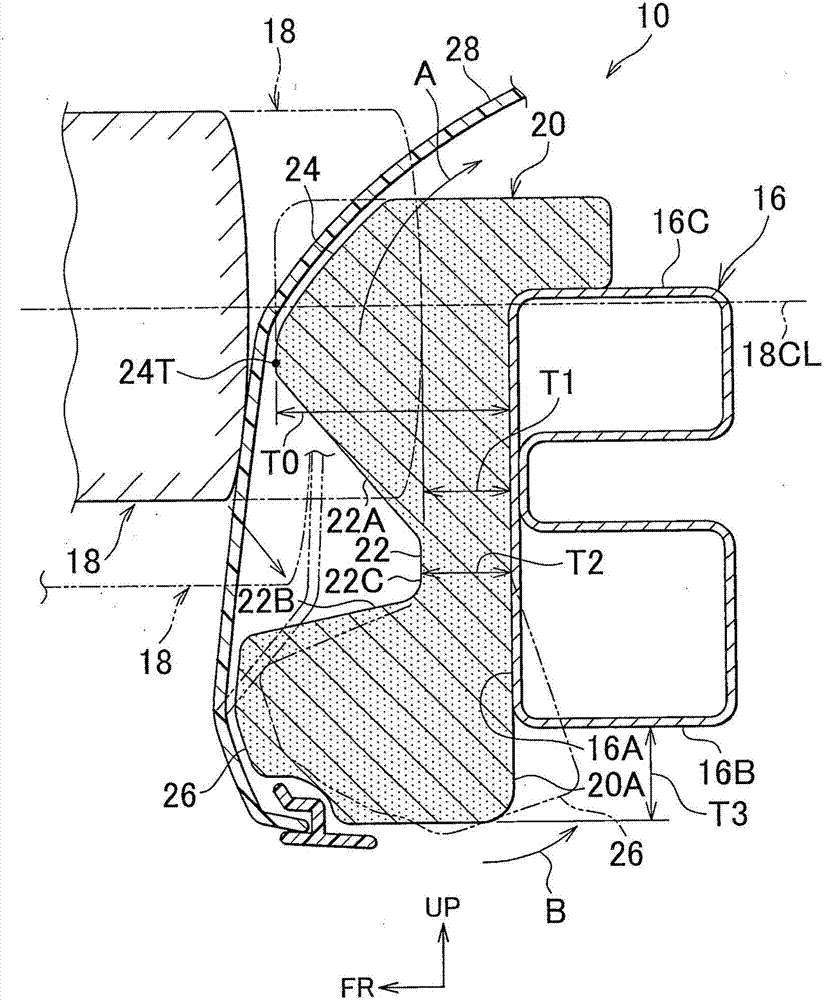

[0081] Next, we will refer to Image 6 A bumper structure of a third embodiment of the present invention is described. Note that the same elements as those in the first embodiment are denoted by the same reference numerals, and descriptions thereof will be omitted. The third embodiment is an example of incorporating a bumper structure of one aspect of the present invention in a front bumper of a vehicle that is relatively high in height such as an RV.

[0082] like Image 6 As shown, the vertical height of the top surface 16C of the bumper reinforcement 16 relative to the vertical center height 18CL of the barrier 18 in the third embodiment is set higher than that in the first embodiment, measured from the road surface. The vertical height of the top surface 16C of the bumper reinforcement 16 relative to the vertical center height 18CL of the barrier 18. The upper portion of the bumper absorber 20 protrudes upward beyond the top surface 16C of the bumper reinforcement 16 (r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com