Load supporting surface

A technique for supporting surfaces, supporting structures, applied in the direction of chairs, drawing tables, stools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

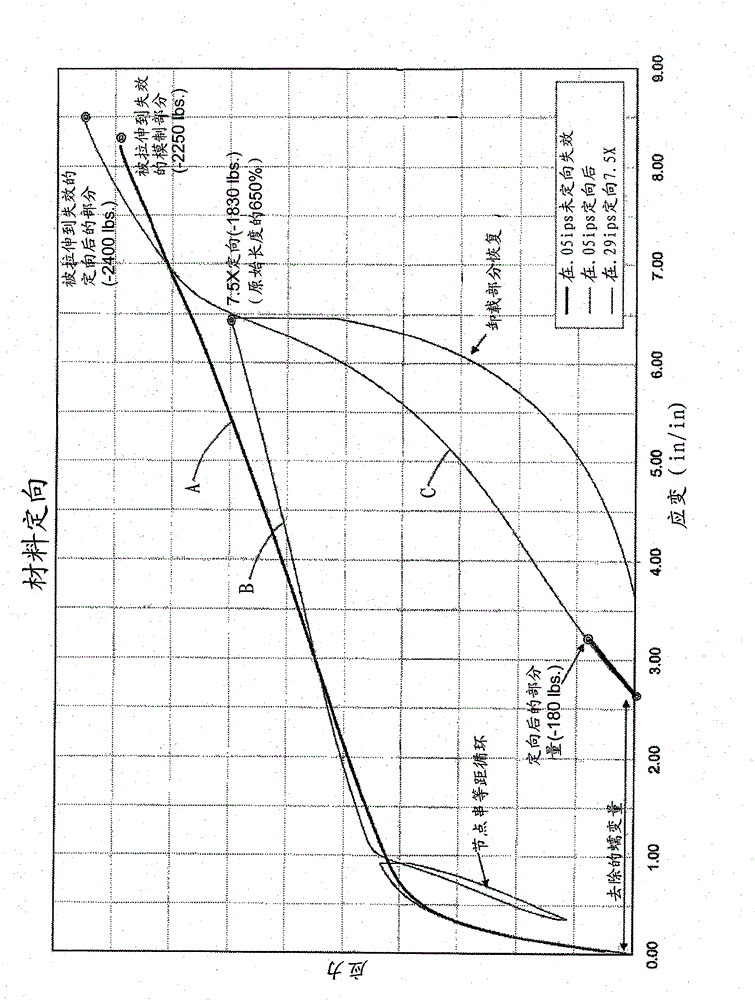

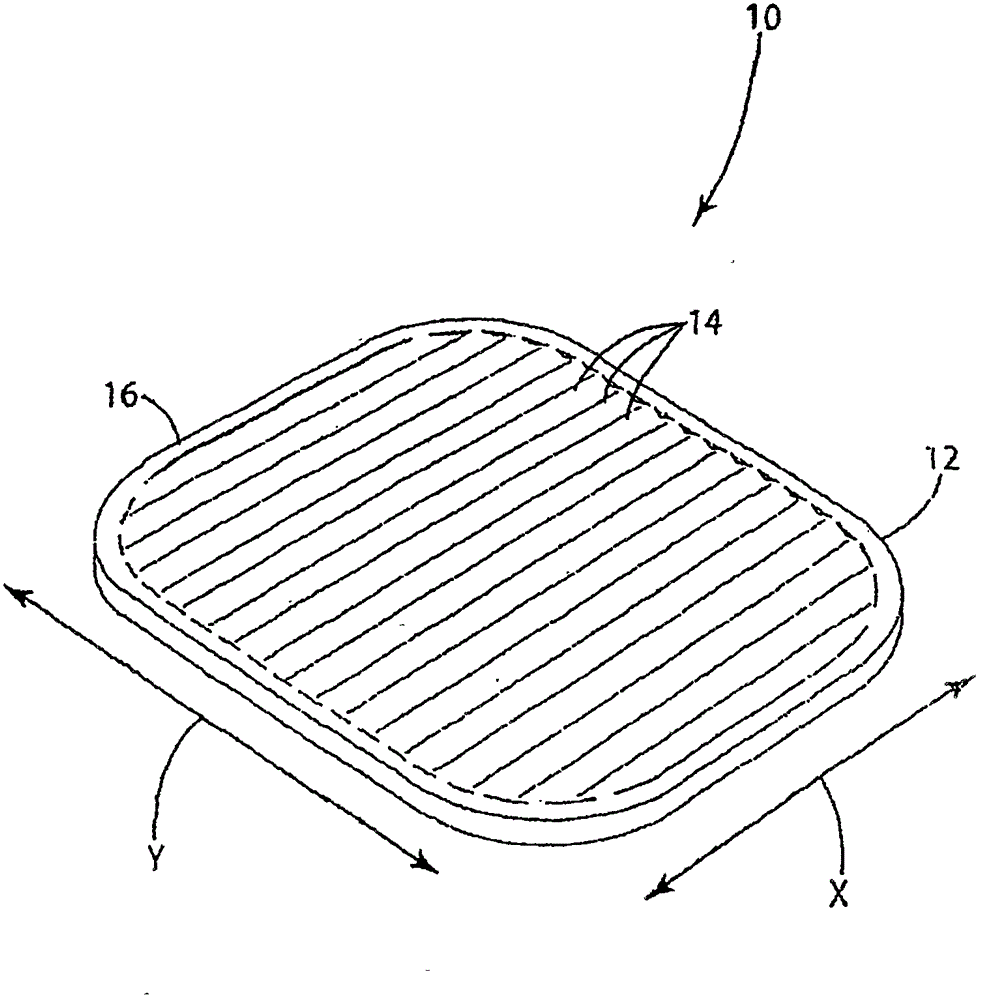

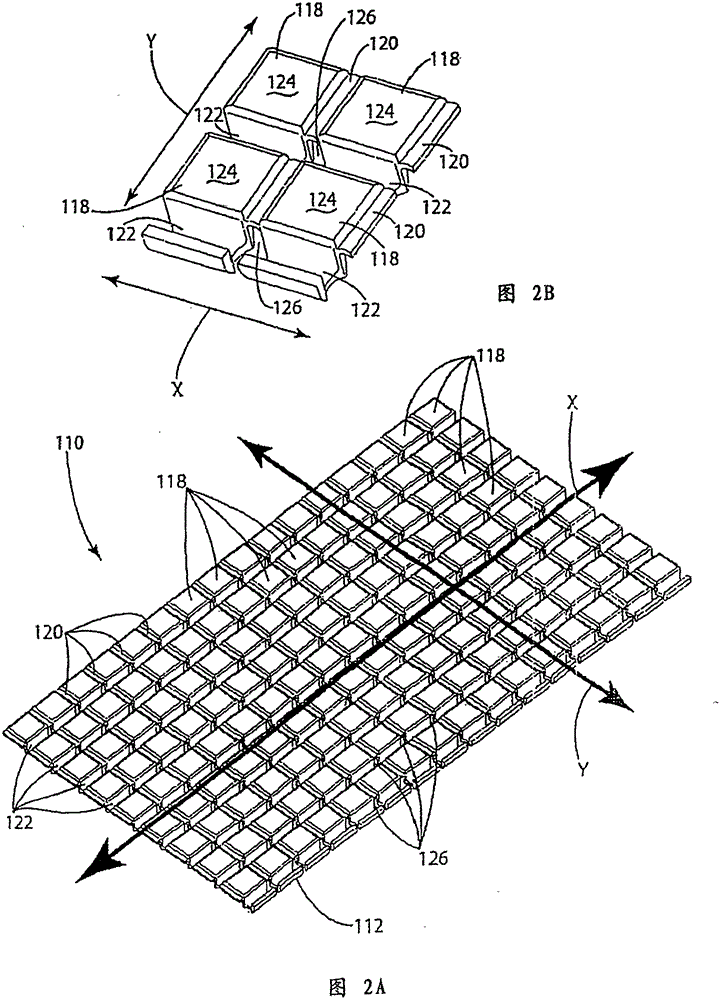

[0047] figure 1 A load bearing surface 10 according to one embodiment of the invention is shown in . figure 1 The load bearing surface 10 shown in is suspendable from a support structure such as a chair seat frame 100 ( Figure 18 with 19 shown) on the molded film. The load supporting surface 10 has different supporting properties in different directions. For example, a load bearing surface may provide significant elastic support in the x-direction and less support in the y-direction. This "divided" support characteristic of the load bearing surface provides a high level of comfort. By way of disclosure, the invention is described in connection with various alternative embodiments primarily for seating applications. However, the present invention is not limited to use in seating applications, but may also be incorporated into other load support applications. The support properties of the molded membrane are highly adjustable, making the load supporting surface 10 suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com