Total-length traveling rotary pile-passing beam bottom inspection vehicle system

A technology for checking vehicles and passing piers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of a large number of inspection vehicles on the whole bridge, difficult maintenance of inspection vehicles, and cumbersome maintenance operations, etc., and achieves excellent economic indicators. , The effect of convenient beam bottom inspection and low external demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

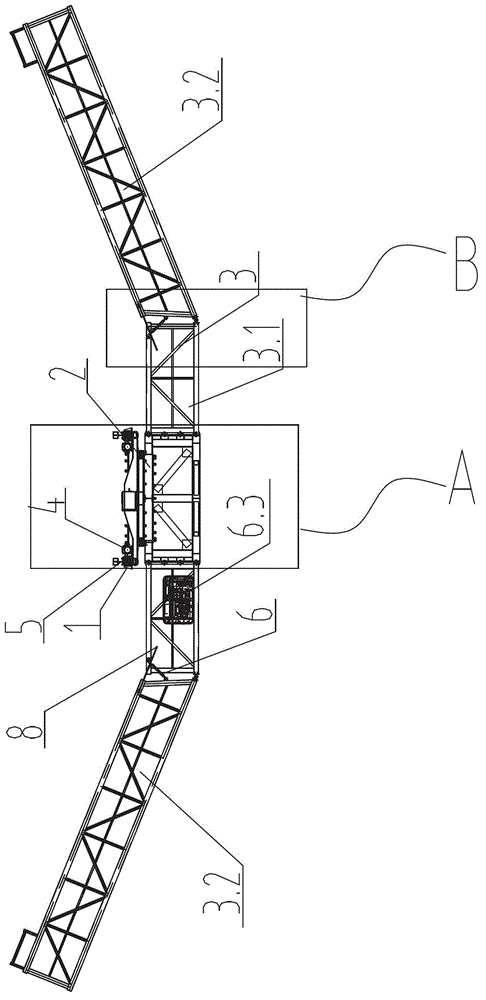

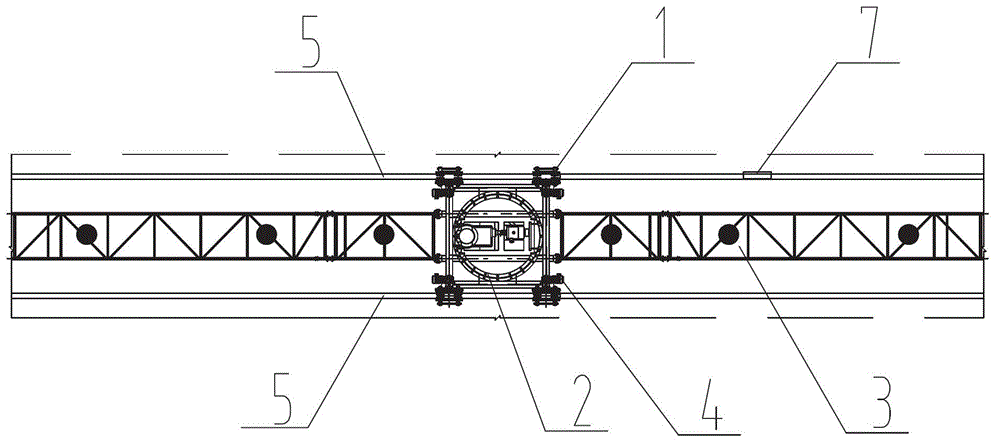

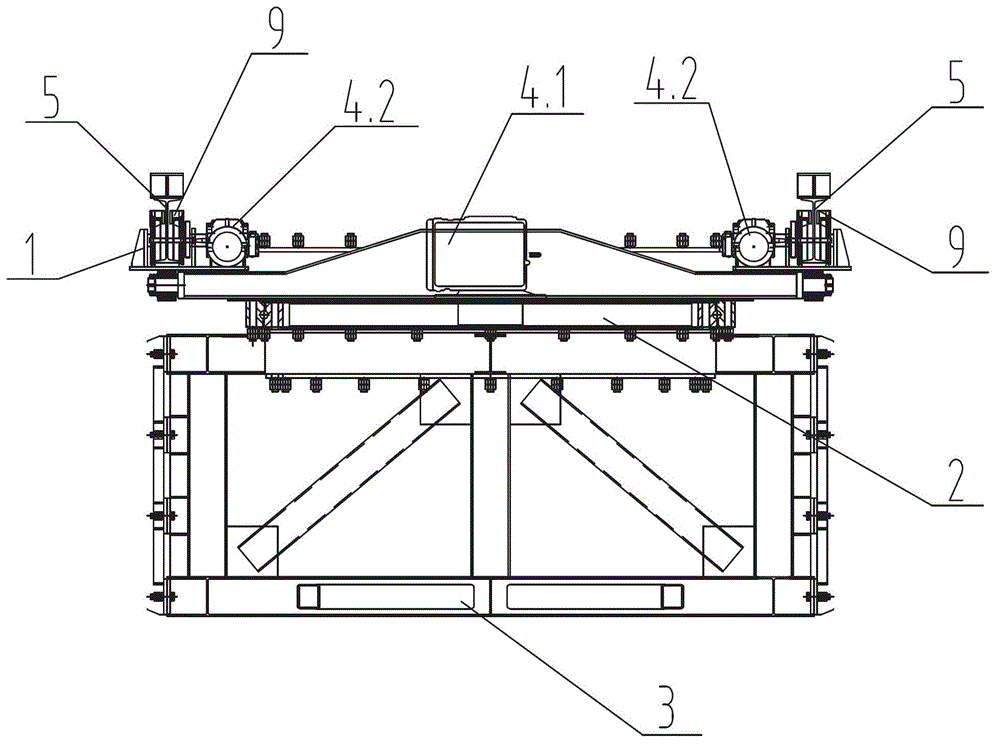

[0023] Such as figure 1 As shown, the inspection vehicle system for long-travel and rotating through the bottom of the pier beam includes the inspection vehicle track 5, the travel mechanism 1, the travel drive system 4 and the frame 3. The frame 3 includes a truss 3.1 and a folding arm 3.2 set at both ends of the truss 3.1 A luffing mechanism 6 for controlling the lifting amplitude of the folding arm 3.2 is arranged between the truss 3.1 and the folding arm 3.2, and a rotating device 2 that allows the frame 3 to rotate horizontally is arranged on the truss 3.1. Such as figure 2 As shown, the inspection vehicle rail 5 is provided with a detection element 7 for detecting the rotation position.

[0024] Combine figure 1 , Figure 4~5 The frame 3 is provided with a safety protection device 8 connecting the truss 3.1 and the folding arm 3.2. The safety p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com