Coupling production process of preparing ethanol from acetic acid

A production process, the technology of acetic acid, is applied in the field of coupled production process of acetic acid to ethanol, which can solve the problems of low conversion rate and selectivity of catalyst, increase of raw material cost, loss of ethanol, etc., to increase the added value of the factory, high hydrogen utilization rate, The effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

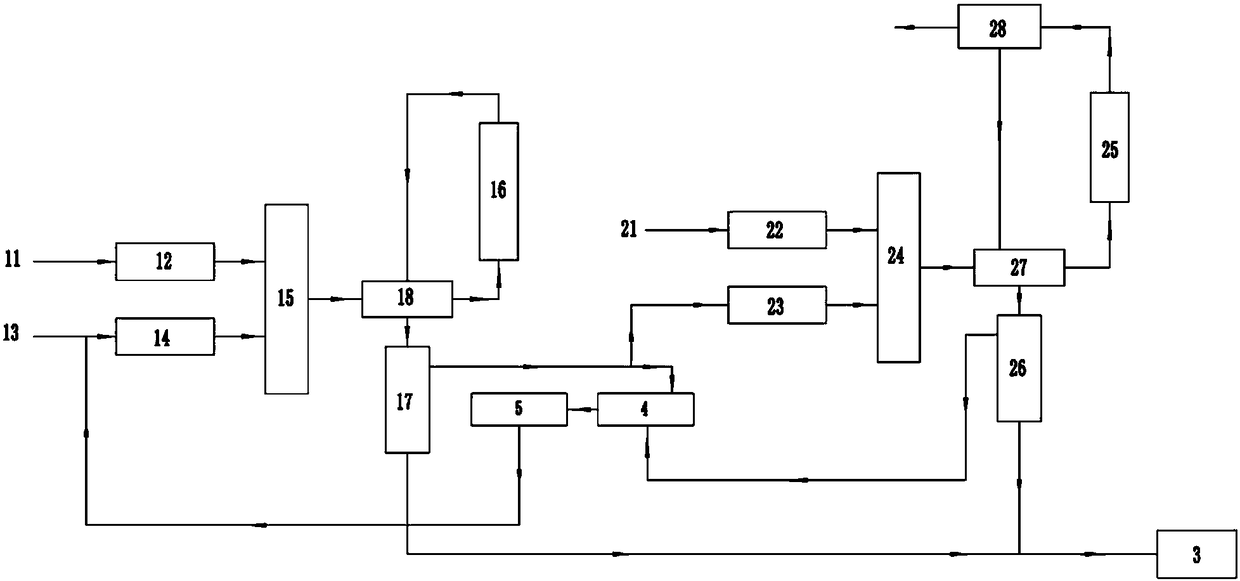

Method used

Image

Examples

Embodiment 1

[0048] A coupled production process for preparing ethanol from acetic acid, using acetic acid and acetate as reaction raw materials, including three sections of hydrogenation of acetic acid, hydrogenation of acetate and purification of crude product. The specific steps are:

[0049] A. Hydrogenation of acetic acid

[0050] Acetic acid and hydrogen are preheated separately and enter the vaporization device Ⅰ for vaporization and mixing. After being heated by the heat exchange unit, they are sent to the bottom of the reactor Ⅰ. The reaction mixture flows upwards, passes through the hydrogenation catalyst bed of the reactor Ⅰ, and undergoes catalytic hydrogenation. react to generate ethanol; the catalyst is a supported platinum / silver catalyst, the reaction temperature is 300-320° C., and the reaction pressure is 3.0-4.0 MPa.

[0051] The reaction product enters the gas-liquid separator Ⅰ for separation, and the liquid crude ethanol is directly sent to the crude product purifica...

Embodiment 2

[0058] A coupled production process for preparing ethanol from acetic acid, using acetic acid and acetate as reaction raw materials, including three sections of hydrogenation of acetic acid, hydrogenation of acetate and purification of crude product. The specific steps are:

[0059] A. Hydrogenation of acetic acid

[0060] Acetic acid and hydrogen are preheated separately and enter the vaporization device Ⅰ for vaporization and mixing. After being heated by the heat exchange unit, they are sent to the bottom of the reactor Ⅰ. The reaction mixture flows upwards, passes through the hydrogenation catalyst bed of the reactor Ⅰ, and undergoes catalytic hydrogenation. react to generate ethanol; the catalyst is a loaded platinum / silver catalyst, the reaction temperature is 320-340° C., and the reaction pressure is 2.5-3.5 MPa.

[0061] The reaction product enters the gas-liquid separator Ⅰ for separation, and the liquid crude ethanol is directly sent to the crude product purificatio...

Embodiment 3

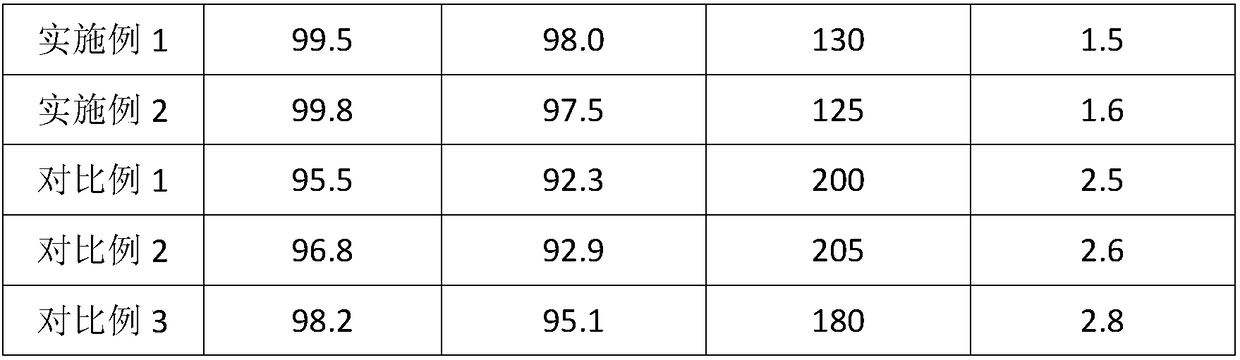

[0068] This embodiment is Comparative Example 1.

[0069] The reaction conditions of this example are basically the same as those of Example 1, the difference being that only the acetic acid hydrogenation section and the crude product purification section are carried out; the hydrogen-rich tail gas produced in the acetic acid hydrogenation section directly enters the waste gas treatment system and does not participate in the cyclic reaction. The hydrogenation catalyst of the acetic acid hydrogenation section, the hydrogenation reaction parameters and the parameters of the crude product purification section are all the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com