Conversion valve for vacuum pump of cutting machine

A vacuum pump and cutting machine technology, applied in pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems of short service life, unreasonable design of steering valve structure, frequent vacuum pump startup, etc., to reduce production costs, avoid The effect of frequent startup and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

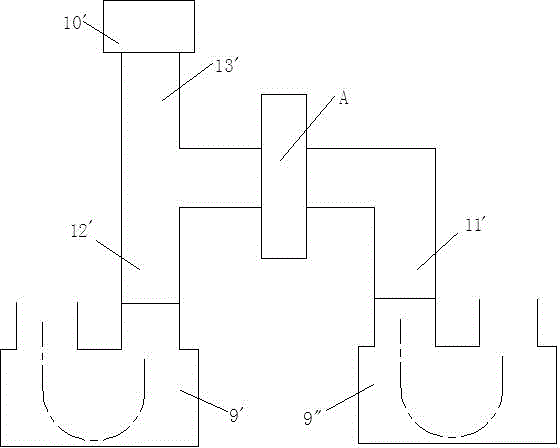

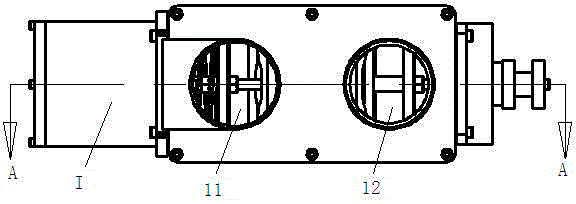

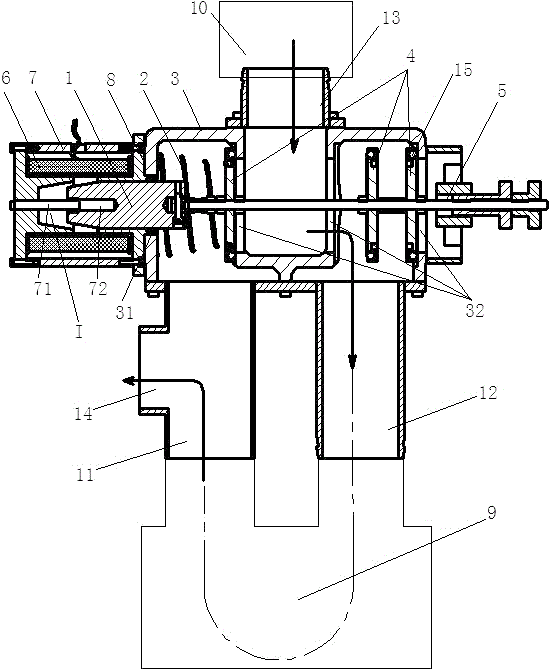

[0017] Embodiment 1: as Figures 2 to 4 As shown, this embodiment includes a moving iron core 1 , a return spring 2 , a valve body 3 , a piston rod 5 , a piston 4 , an enameled coil 6 , an iron core shell 7 and an iron core flange 8 .

[0018] The connection relationship is: the outlet chamber 10 is provided with an outlet port 11 connected to the outlet port of the vacuum pump 9, and the inlet chamber is provided with an inlet port 12 connected to the inlet port of the vacuum pump 9. The middle chamber is located in the middle of the air outlet chamber and the air inlet chamber. The middle chamber is provided with a working end interface 13 connected with the air chamber 10 of the cutting machine. There are air holes on the two partitions between the middle chamber and the air outlet chamber and the air inlet chamber. 32, the air inlet cavity end of the valve body 3 also has an air hole 32, and the air outlet cavity end of the valve body 3 has a mounting hole 31; the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com