Fully-sealed ceramic electric heating ring

An electric heating coil, fully sealed technology, applied in the direction of the heating element shape, etc., can solve problems such as shutdown maintenance, conductive liquid penetration, short circuit, etc., to avoid internal short circuit and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

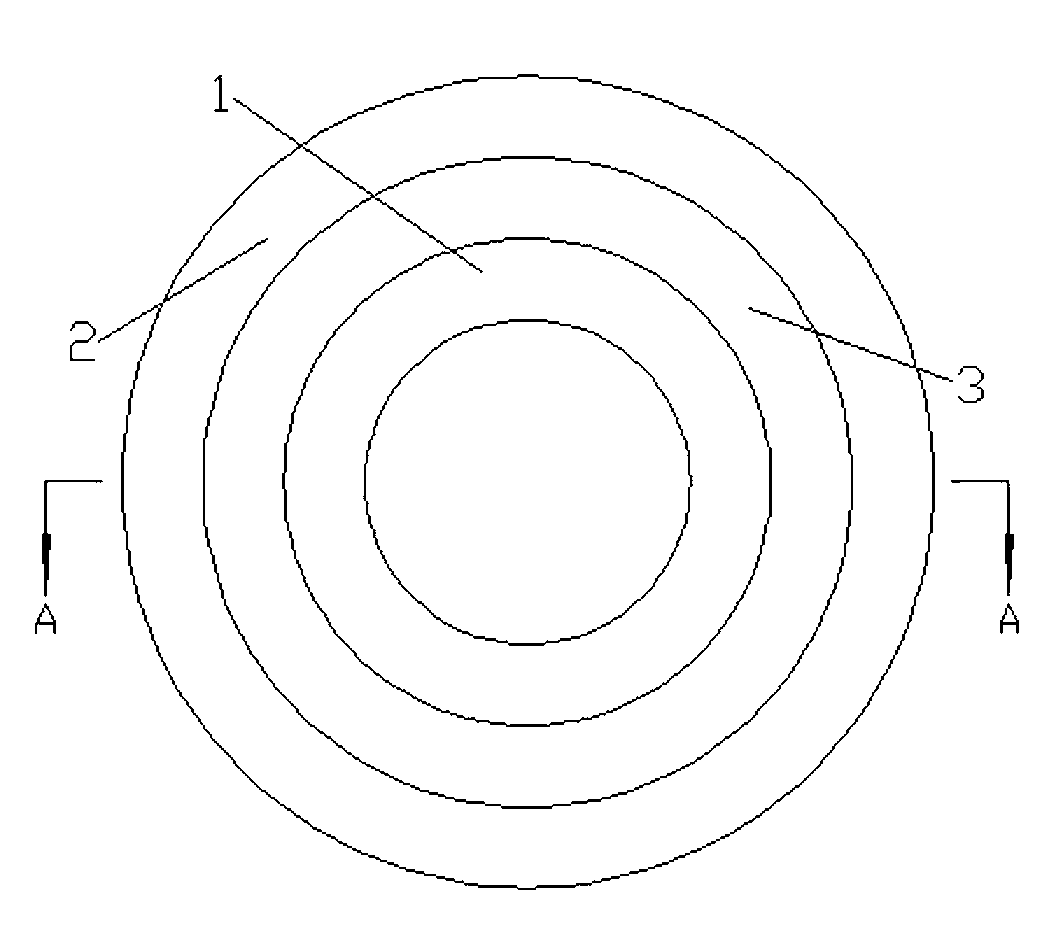

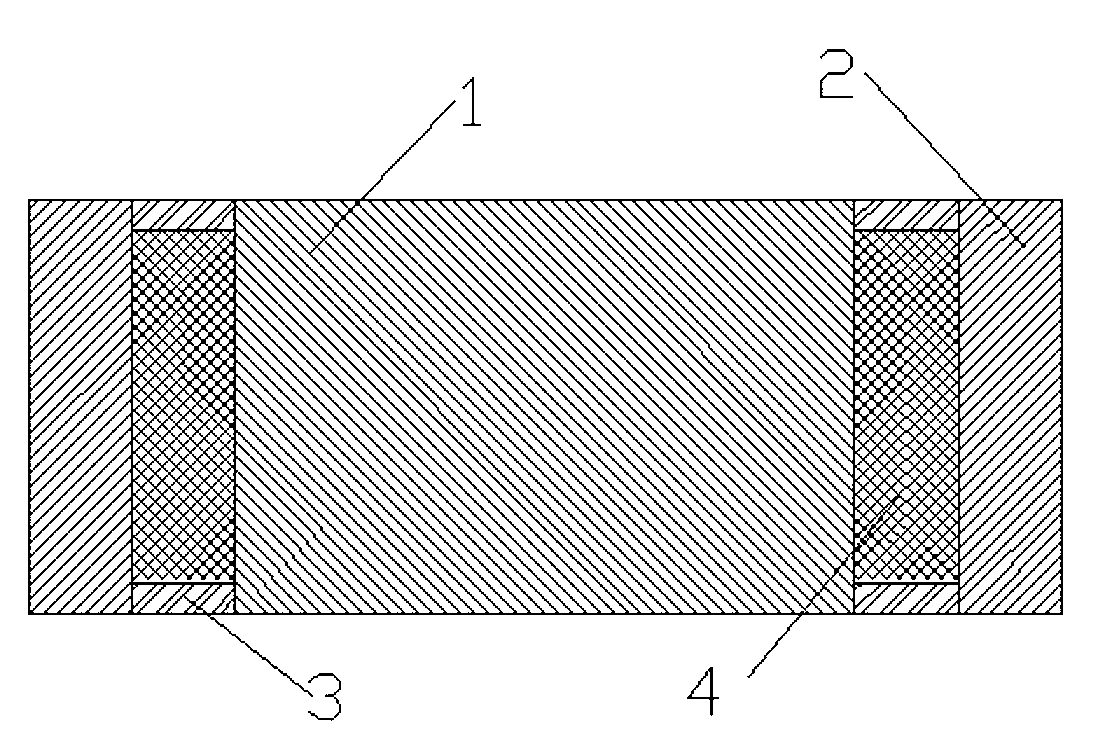

[0013] As shown in the accompanying drawings, a fully sealed ceramic heating ring includes a heating ring body 4, and the inside and outside of the heating ring body 4 are respectively fitted with an inner protection ring 1 and an outer protection ring 2, and the inner protection ring 1 and the outer protection ring 2 are the same. Shaft and equal height, the inner protective ring 1 and the outer protective ring 2 are connected into one body by welding a connecting ring 3 at each end of the top and the bottom. The materials of the inner protective ring 1, the outer protective ring 2 and the connecting ring 3 can be the same material, such as stainless steel, which is convenient for argon arc welding and sealing, so that the inner protective ring 1, the outer protective ring 2 and the connecting ring 3 are connected into a compact one, In this way, the body of the heating coil is completely sealed, and it is difficult for the conductive liquid to penetrate into the body of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com