Automatic feeding system for breeding industry

A farming and automatic technology, applied in animal feeding devices, poultry farming, animal husbandry, etc., can solve problems such as waste of feed, feed layering, pollution, etc., to reduce labor costs, reduce feed waste, and avoid contact infection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

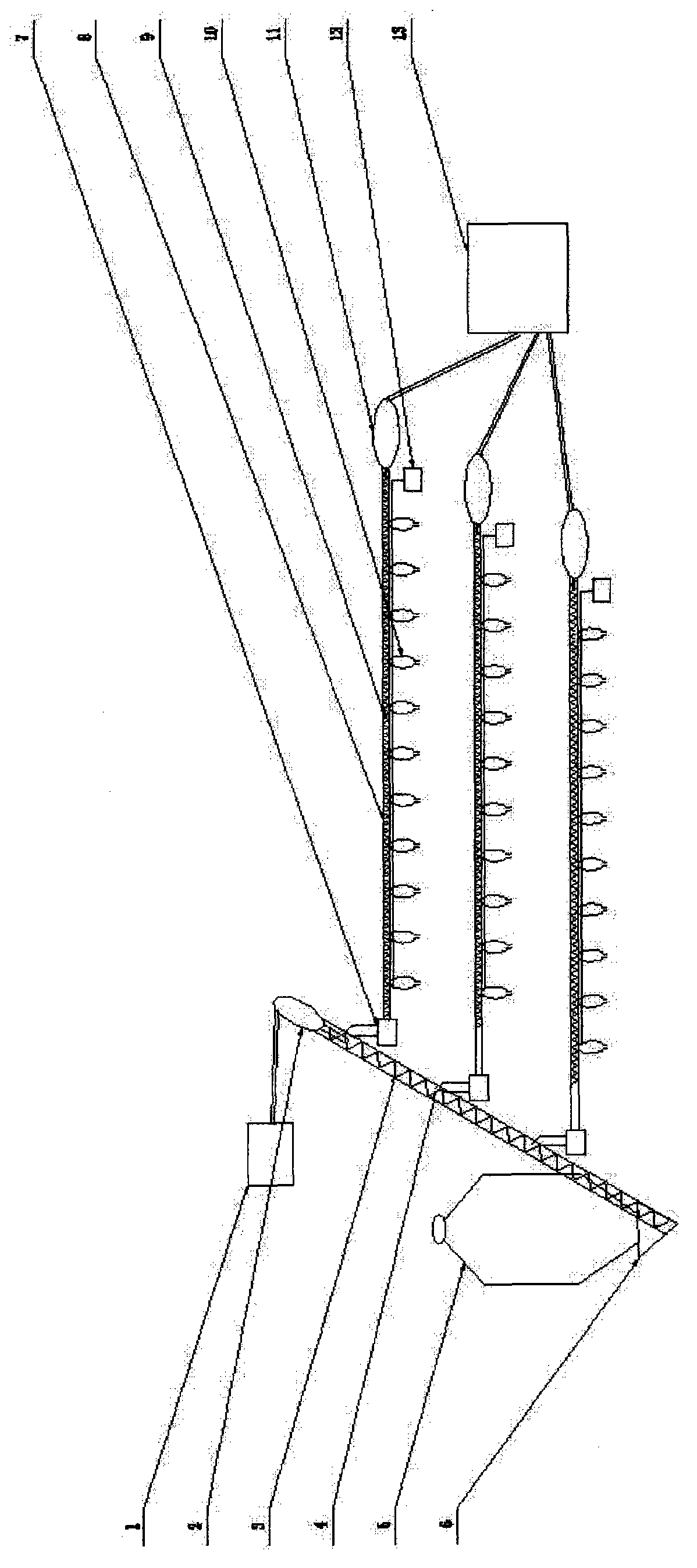

[0036] like figure 1 As shown, an automatic feeding system for aquaculture consists of two parts: a main feed line and a feed distribution line;

[0037] The main material line is mainly composed of a material tower (silo) 5, a main material line unloading device 6, a main material line conveying pipe 3, a main material line auger 4, a main material line motor 2, and a main material line electric control device (Main material line electric control system) 1 composition;

[0038] The material tower 5 is connected with a main material line unloading device 6, the main material line unloading device 6 is connected with the main material line conveying pipe 3, and the main material line conveying pipe 3 is provided with a main material line An auger 4, the main material line auger 4 is connected with the main material line motor 2, and the main material line motor 2 is connected with the main material line electric control device 1;

[0039] The material distribution line is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com