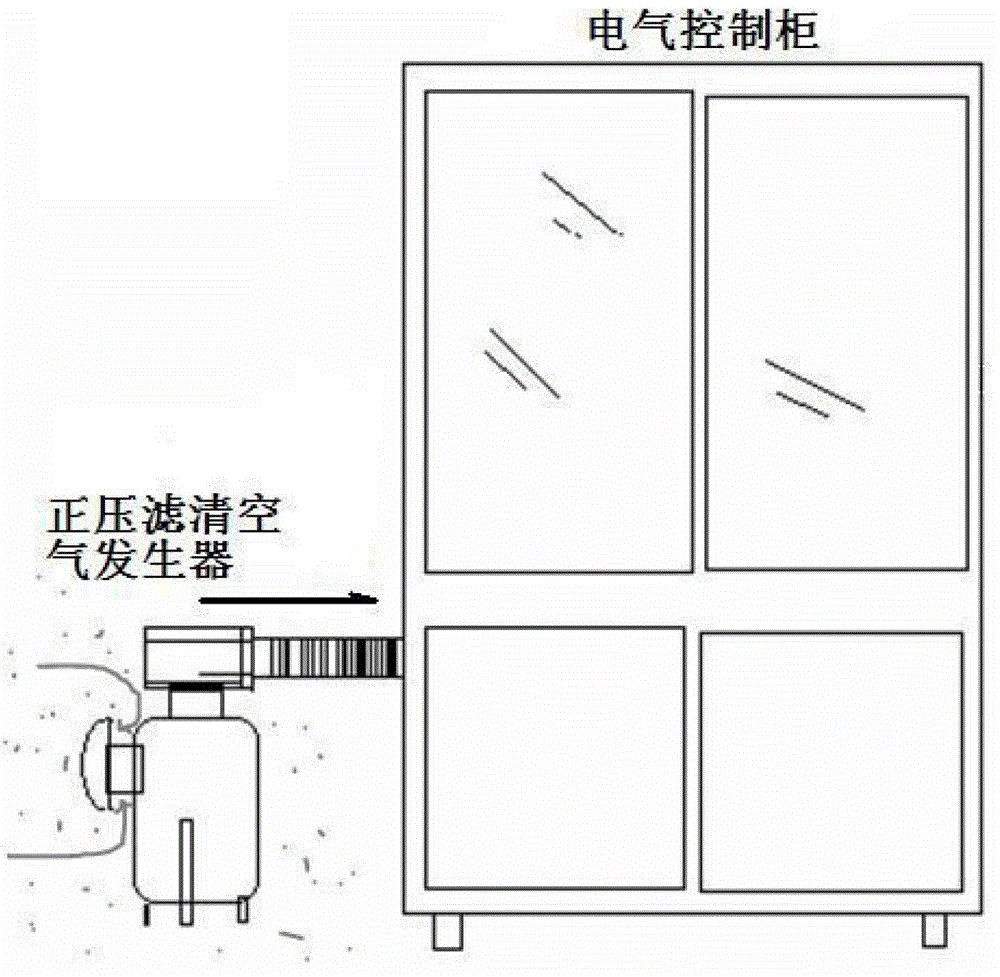

Positive pressure filtration air generator

An air generator and filter technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of closed electrical rooms, cabinets, and boxes with complex structures and high costs, and achieve good dust-proof effect, Low cost and obvious filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

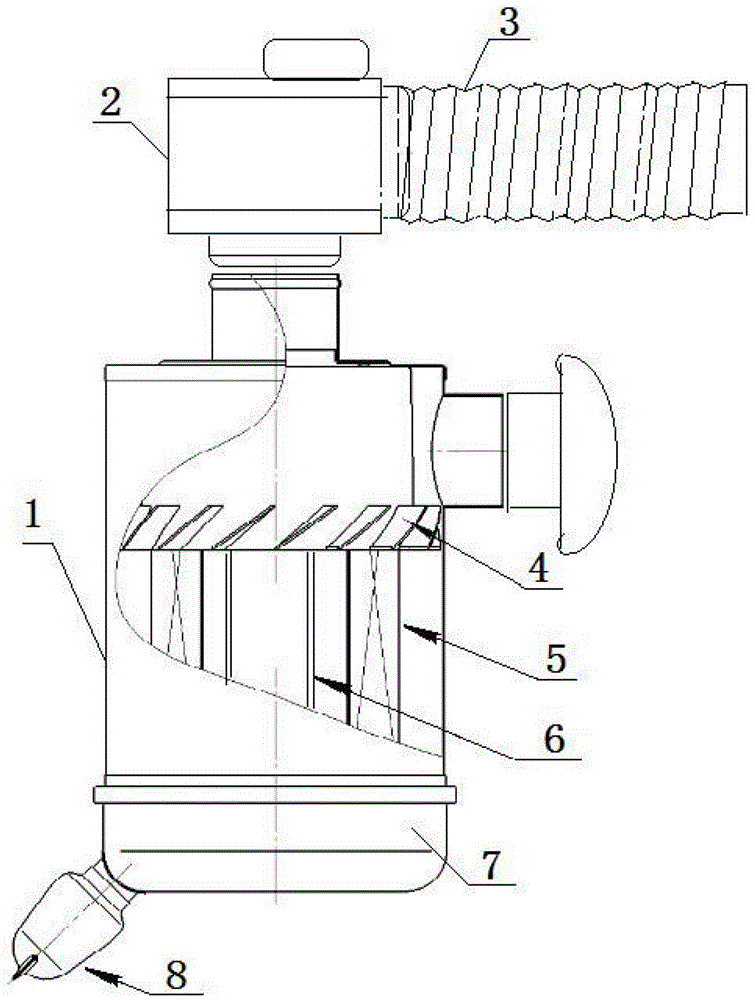

[0015] The positive pressure filter air generator of the present invention includes a multi-stage dry air filter 1 , a centrifugal fan 2 and a hose 3 . The multi-stage dry air filter 1 is composed of cyclone guide vanes 4 , the second stage is a safety filter element 5 , the third stage is a fine filter element 6 , a dust collection chamber 7 and a dust discharge sealing port 8 . The cyclone guide vanes 4 and the air inlet shell form the first stage cyclone separator.

[0016] The centrifugal fan 2 is powered on and the dust air is inhaled from the air inlet of the multi-stage dry air filter 1. The dust is separated by the first cyclone centrifuge of the multi-stage dry air filter 1, and the heavier dust particles flow along the circular cavity. The wall flows down to the dust collection chamber 7, and the relatively light dust is filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com