One-off forming device for making gear workpiece with internal and external teeth

An internal and external tooth, one-time technology, applied in the direction of metal extrusion dies, etc., can solve problems such as unqualified workpieces, and achieve the effects of low processing cost, high raw material utilization rate, and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

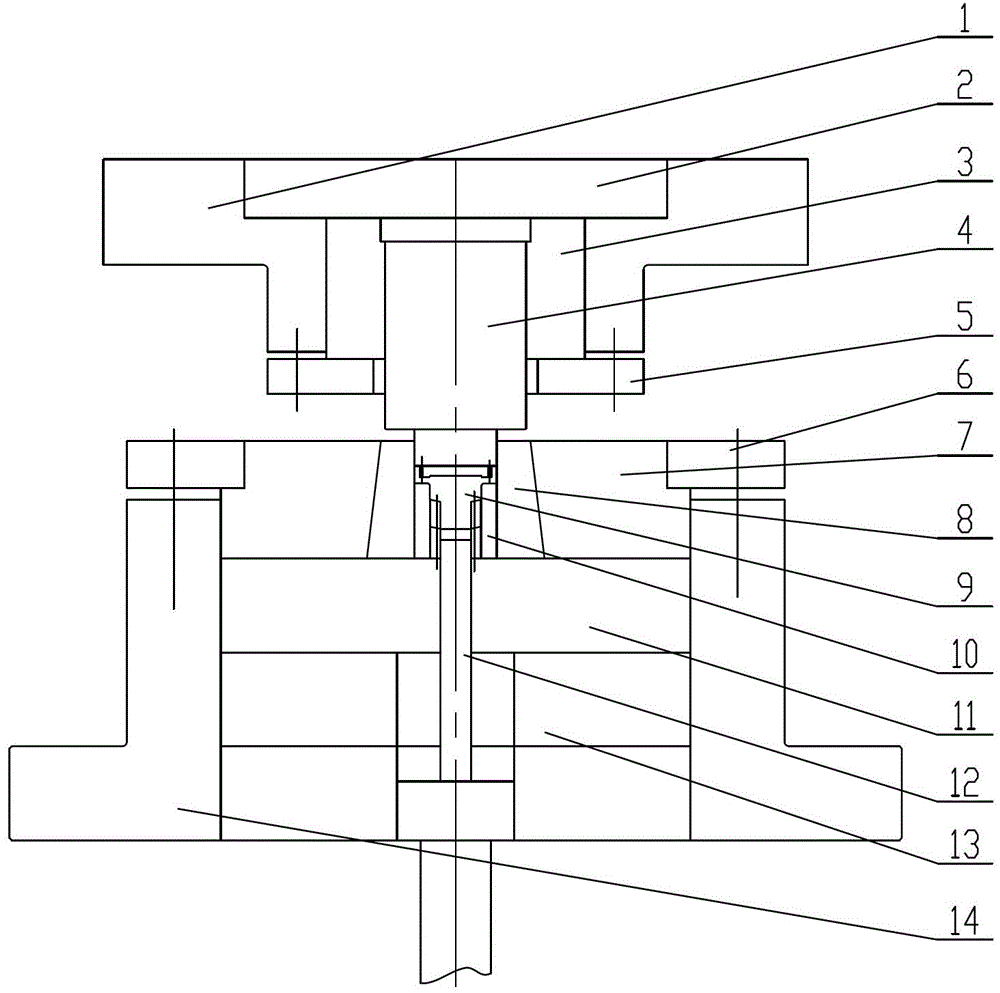

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

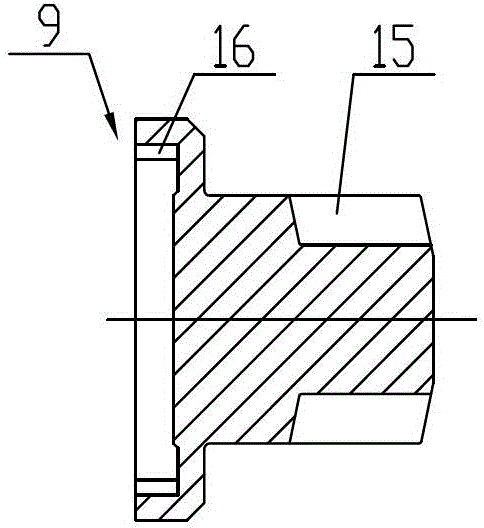

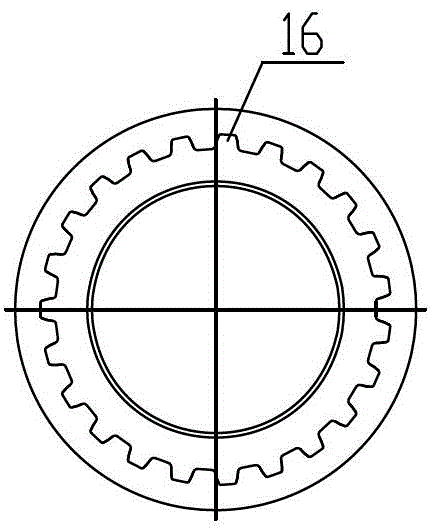

[0016] Figure 1~Figure 4 Among them, including upper die base 1, upper die cushion block 2, upper die fixing sleeve 3, upper die for inner tooth forming upper punch 4, upper die pressing plate 5, lower die pressing plate 6, lower die 7, punch guide sleeve 8, gear The workpiece 9, the outer tooth forming die 10, the lower concave mold cushion block 11, the ejector device 12, the adjustment cushion block 13, the lower mold base 14, the outer tooth 15, the inner tooth 16, etc.

[0017] Such as Figure 1~Figure 4 As shown, the present invention is a one-time forming device for a gear workpiece with internal and external teeth, including an upper mold and a lower mold.

[0018] The upper die includes an upper die base 1 and an upper punch 4 for internal tooth forming installed in the upper die base 1 , the cross-sectional shape of the upper pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com