Molding die for sheet material with reversed bound edge

A technology of forming molds and reverse edging, which is applied to the field of forming molds with reversed edging sheets, can solve the problems of reverse edging of shells, etc., and achieves the effect of convenient operation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

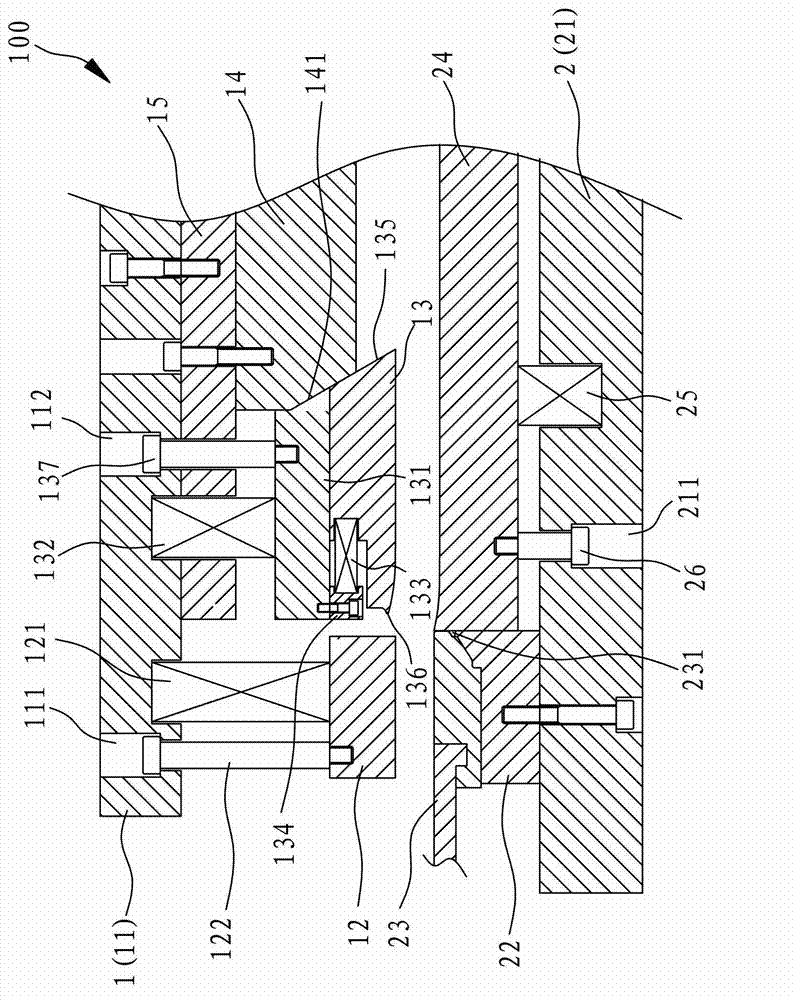

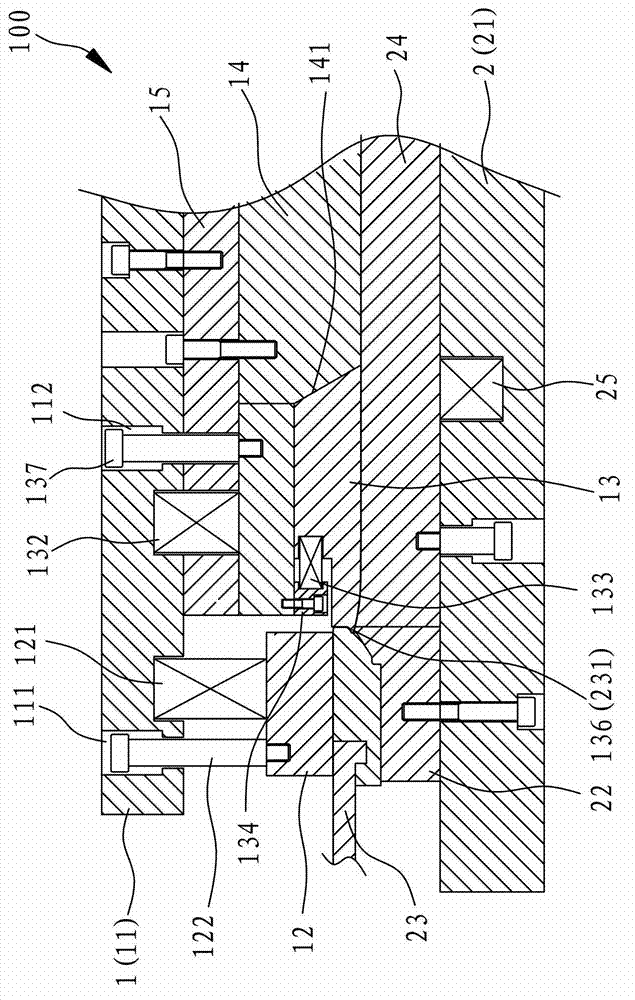

[0034] Such as figure 1 with figure 2 As shown, the present invention relates to a forming mold 100 with an over-wrapped sheet material, including an upper mold assembly 1 and a lower mold assembly 2. The upper mold assembly 1 and the lower mold assembly 2 can be opened and closed. Used to form sheets with reverse-wrapped edges.

[0035] The upper mold assembly 1 has an upper mold seat 11, an upper pressing plate 12, a pressing spring 121, an oblique slider 13, an oblique punch 14, a guide block 131, an upper mold spring 132, a slider return spring 133, and a spring stopper. Plate 134; the pressing spring 121 is arranged between the upper pressing plate 12 and the upper mold base 11, thereby preventing the upper pressing plate 12 from approaching the upper mold base 11. Specifically, in this embodiment, a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com