Preparation method of gum

A technology of self-adhesive and double-sided adhesive, applied in the direction of adhesives, film/sheet adhesives, metal processing, etc., can solve the problems of easy generation of foreign objects, high manufacturing costs, easy size deviation, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a detailed description of the preparation method of back-shaped back glue (frame glue) for one-time punching and molding waste in conjunction with the accompanying drawings.

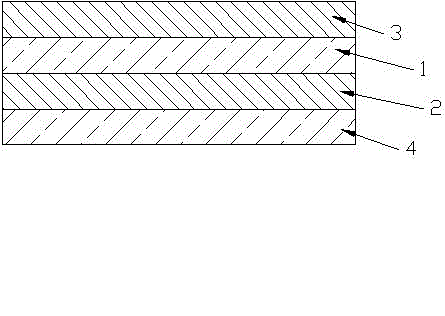

[0022] fit: see figure 1 , attach the double-sided adhesive 1 to the release surface of the release film (B release film) 2 with a release force of 60g±5g; Attach the release surface of the release film (A release film) 3; attach the 40G protective film (C protective film) 4 to the non-release surface of the release film with a release force of 60g±5g.

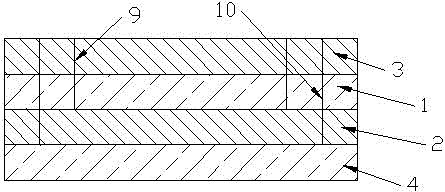

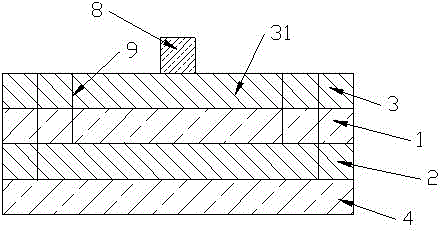

[0023] Die-cut: see figure 2 , 3 , use a forming knife die to die-cut on the bonded material, the knife die faces the 3-5g release force release film, the inner frame of the knife die cuts off the 3-5g release force release film and double-sided tape, the knife 3-5g release force release film, double-sided adhesive, 60g ± 5g release force release film are cut off by the outer frame of the mold; 3-5g release force release film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com