Excavating shovel bucket with face and back operation functions

A front and back double-sided, excavating shovel technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of complex structure and difficult switching of front and back shovel operations, and achieve the effect of simple switching and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

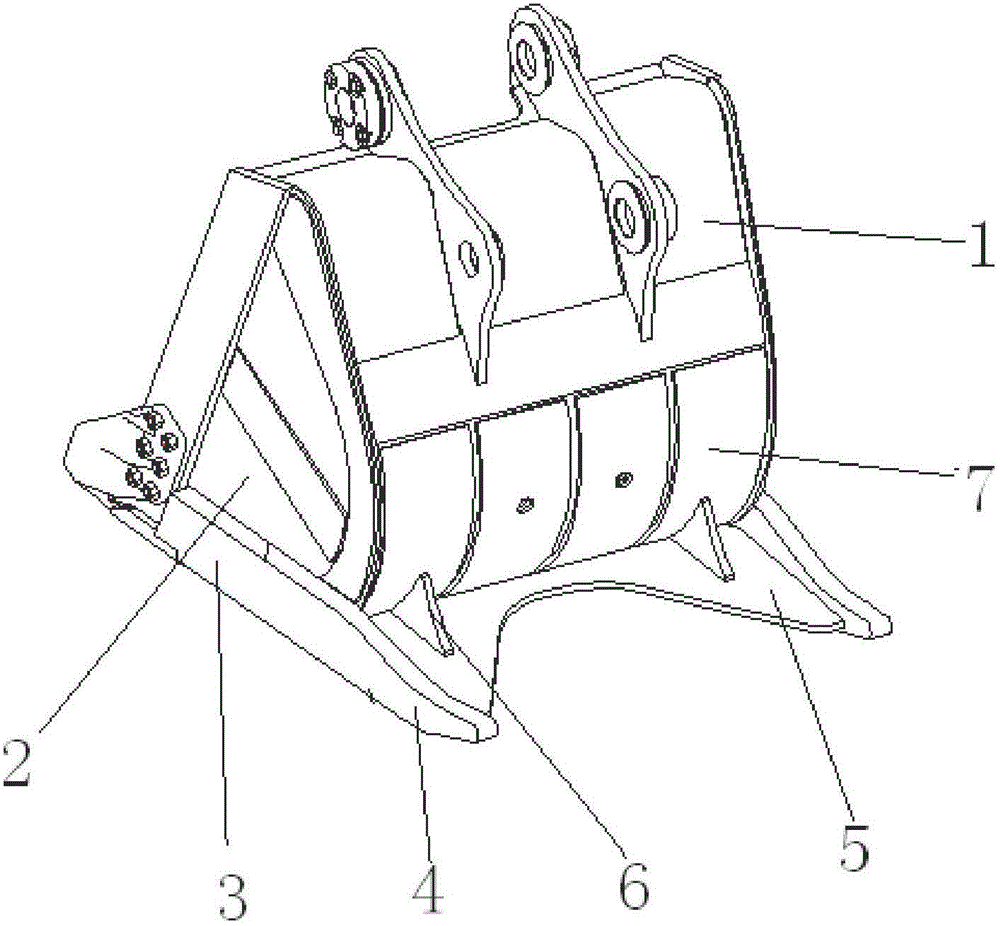

[0018] In this embodiment, the excavating bucket with the function of front and back double-sided operation is as follows: figure 1 As shown, it includes a backhoe bucket 1 and a front shovel excavation device. The front shovel excavation device is roughly H-shaped, and it includes two strip-shaped main force plates 3, and the two main force plates 3 are placed on both sides of the backhoe excavation bucket. The side plates 2 on both sides of the backhoe bucket 1 are welded together, and the rear end of the main force plate 3 extends backward to form a crowbar-shaped prying part 4, and a reinforcing plate 5 is welded between the two prying parts 3, and the welded plate 5 The middle part is sunken in the direction of the back bucket to form a V-shaped gap, and two ribs 6 are welded between the reinforcement plate and the back plate 7 of the back bucket, and the ribs 6 are perpendicular to the reinforcement plate 7 and the back plate of the back bucket .

Embodiment 2

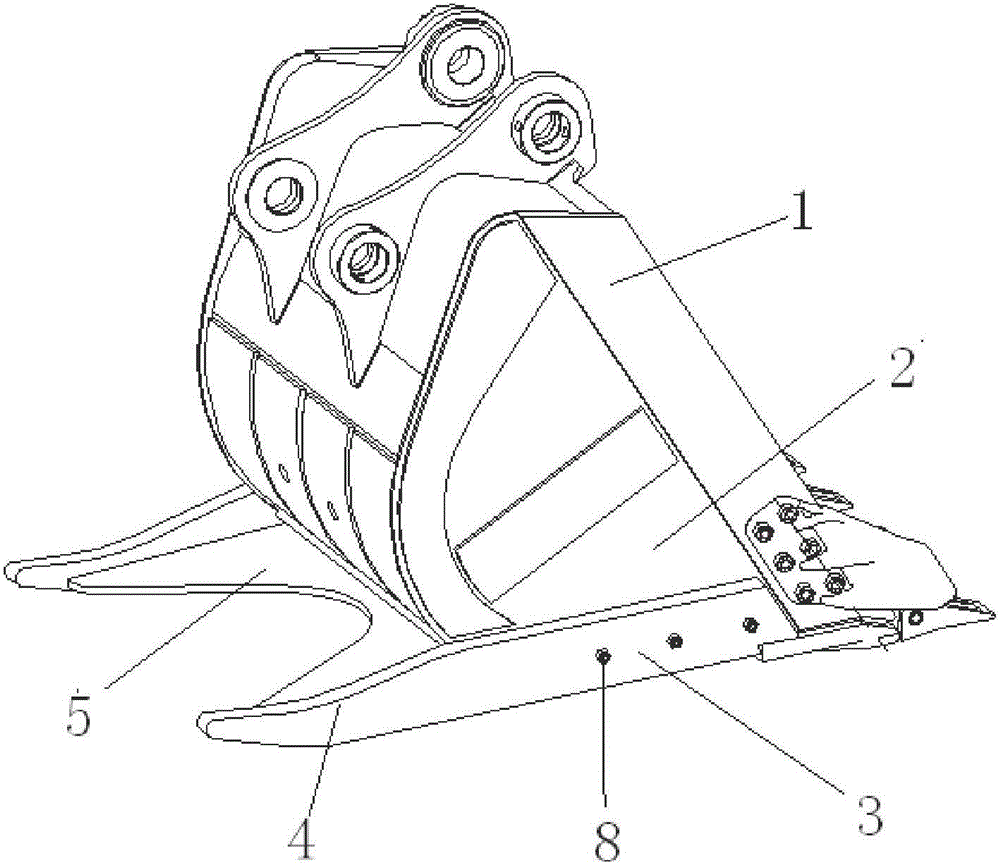

[0020] In this embodiment, the excavating bucket with the function of front and back double-sided operation is as follows: figure 2 As shown, it includes a backhoe bucket 1 and a front shovel excavation device. The front shovel excavation device is roughly H-shaped, and it includes two strip-shaped main force plates 3, and the two main force plates 3 are placed on both sides of the backhoe excavation bucket. The bolt and nut assembly 8 is fixedly connected to the side plates 2 on both sides of the back bucket 1, and the rear end of the main force plate 3 extends backward to a crowbar-shaped prying part 4, and a reinforcing plate is welded between the two prying parts 3 5. The middle part of the welding plate 5 is recessed toward the direction of the back-bucket to form a V-shaped gap. In this embodiment, if the front shovel excavation device is not needed in the operation process, the front shovel excavation device can be disassembled from the back bucket, so as to reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com