Construction method for prefabricated column to be lifted in position for one time

A construction method and prefabricated column technology are applied in the field of hoisting construction, which can solve the problems of high cost of pre-embedded steel hoisting rings, uneven hoisting force, unfavorable finished product protection, etc., so as to improve hoisting efficiency and safety, and improve hoisting quality and work. Efficiency, the effect of avoiding the danger of removing rigging at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

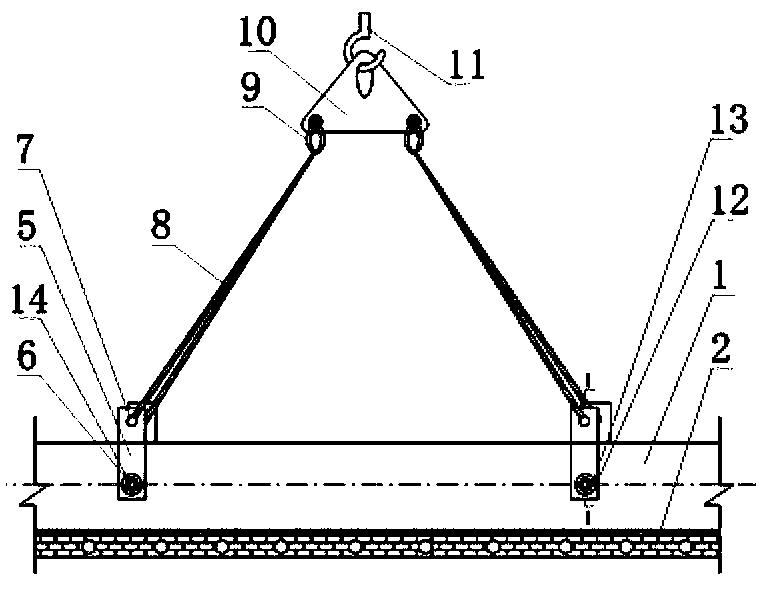

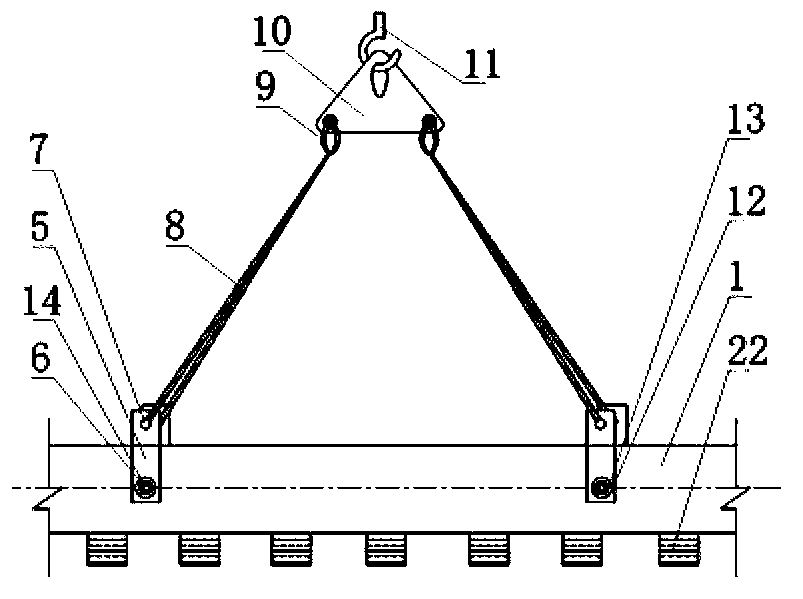

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] The prefabricated column hoisting construction method in place of the present invention specifically includes the following steps

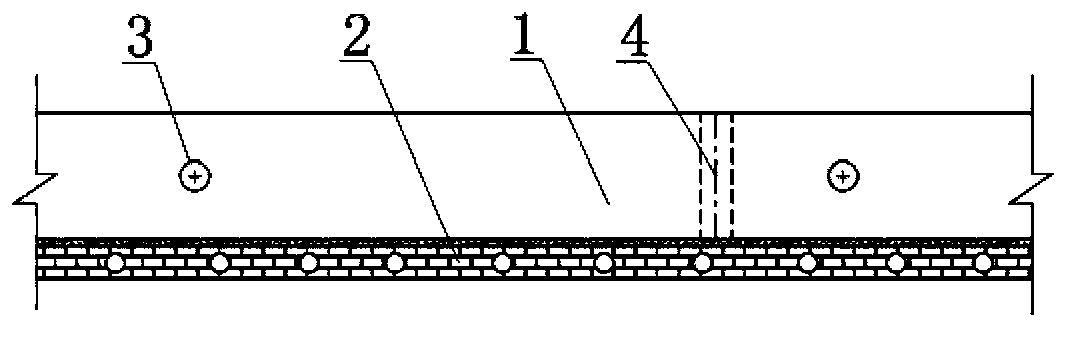

[0024] 1) Before the concrete pouring of the prefabricated column 1, if figure 1 As shown, three PVC pipes are pre-embedded at the design position, two of which are used as turning holes 3, and one is used for lifting holes 4. If it is a corbel-shaped prefabricated column, the lifting holes are pre-embedded under the corbel. The axis directions of the two turning holes 3 are parallel to the brick membrane 2, which is beneficial to the accuracy of the pre-embedded position, and ensures that when the prefabricated column 1 translates and turns over, the angle between the hoisting rope and the horizontal line is 45°, which is balanced and evenly stressed; the lifting holes The 4-axis direction is perpendicular to the brick membrane 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com