Piezoelectric-liquid-actuated elastic-membrane-position electric feedback two-stage servo valve and control method thereof

A technology of elastic film and servo valve, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of small and micro-flow control servo valves with poor reliability, and achieve control without dead zone and high reliability , the effect of high-precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

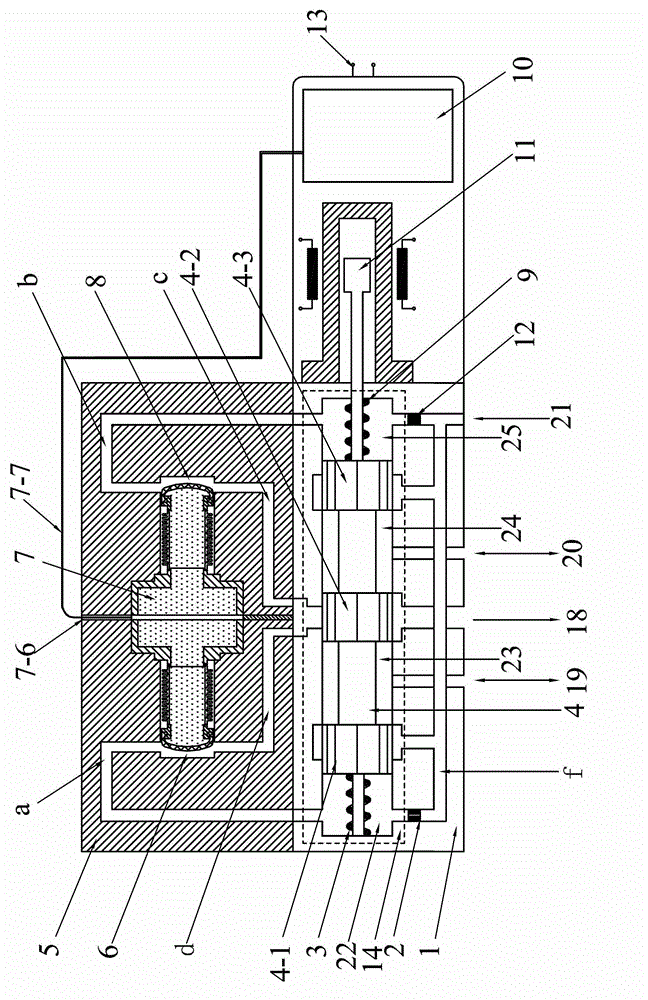

[0032] Specific implementation mode one, combination figure 1 In this specific embodiment, a piezoelectric fluid actuated elastic membrane position electrical feedback type two-stage servo valve, which includes a main valve body 1, a pilot valve body 5 and a servo valve controller 10;

[0033] The main valve body 1 is provided with a No. 1 fixed orifice 2, a displacement sensor 11, a No. 2 fixed orifice 12, a slide valve cavity 14 and a No. 5 flow channel f;

[0034] The pilot valve body 5 is provided with a No. 1 variable orifice 6, a No. 2 variable orifice 8, a piezoelectric hydraulic brake elastic membrane assembly 7, a No. 1 runner a, No. 2 runner b, No. 3 runner c and No. 4 runner d;

[0035] The spool valve cavity 14 is built with a No. 1 balance spring 3, a spool valve 4 and a No. 2 balance spring 9; the side wall of the spool valve cavity 14 is provided with a liquid outlet 18, a No. 1 liquid inlet and outlet 19, and a No. 2 liquid inlet and outlet 20. And the liquid inlet 2...

specific Embodiment approach 2

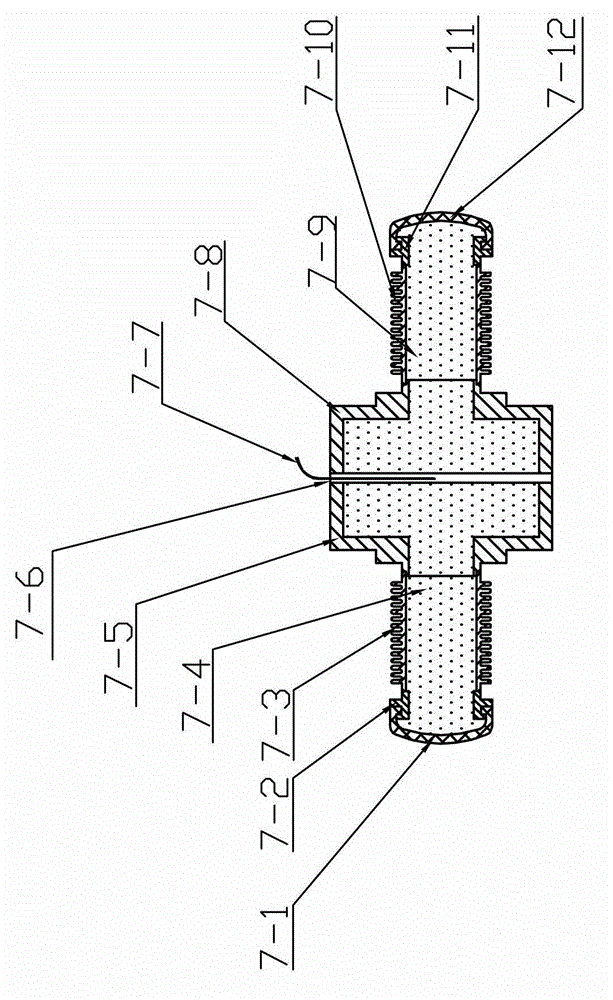

[0047] Specific implementation mode two, combination figure 2 To illustrate this embodiment, this embodiment is a further description of the first embodiment. The piezoelectric hydraulic brake elastic membrane assembly 7 described in this embodiment includes the first elastic mold 7-1 and the first elastic mold fixing frame 7. -2, No. 1 bellows 7-3, first closed cavity 7-4, No. 1 fixing sleeve 7-5, piezoelectric sheet 7-6, No. 2 fixing sleeve 7-8, second closed cavity 7-9, No. 2 bellows 7-10, No. 2 elastic film holder 7-11 and No. 2 elastic mold 7-12;

[0048] The first elastic mold 7-1, the first bellows 7-3, the first fixed sleeve 7-5 and the piezoelectric sheet 7-6 enclose the first closed cavity 7-4; the first elastic mold 7-1 covers the first One end of the bellows 7-3 is connected to the No. 1 bellows 7-3 through the No. 1 elastic mold fixing frame 7-2, and the other end of the No. 1 bellows 7-3 is connected to the piezoelectric through the No. 1 fixing sleeve 7-5. Fixed ...

specific Embodiment approach 3

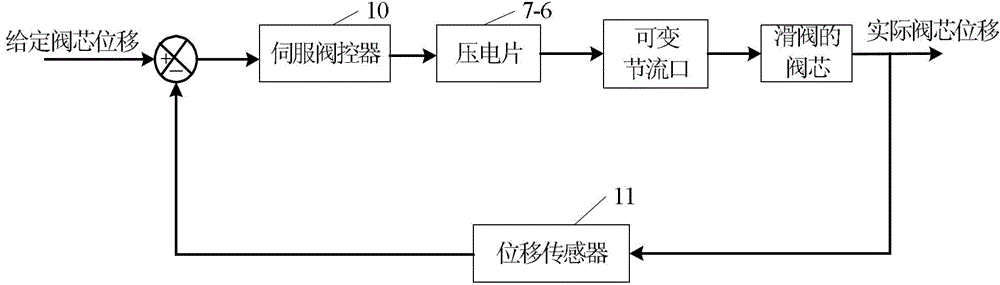

[0050] Specific implementation mode three, combination Figure 1 to Figure 3 In this embodiment, the piezoelectric liquid actuated elastic membrane position electric feedback type two-stage servo valve control method described in this embodiment is described. The realization process of the method is as follows:

[0051] The spool displacement signal of the spool valve is input from an external input device to the servo valve controller 10, and the servo valve controller 10 generates a current excitation signal according to the displacement signal to the piezoelectric sheet 7-6 of the piezoelectric hydraulic brake elastic membrane assembly 7. Piezoelectric sheet 7-6 undergoes deformation, and its degree of deformation is approximately proportional to the magnitude of the excitation current;

[0052] When the input excitation current is a positive current, the piezoelectric sheet 7-6 will deform in the direction where the first elastic mode 7-1 is located, so that the piezoelectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com