Improved fastener seat structure

A buckle seat and mounting hole technology, which is applied in the direction of mechanical equipment, fixing devices, etc., can solve problems such as trouble, shape is difficult to fix, and realization is difficult, so as to achieve the effect of matching flexibility and ensuring a beautiful gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

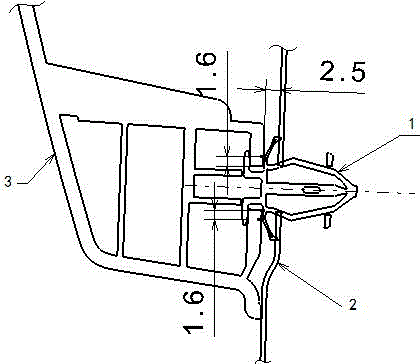

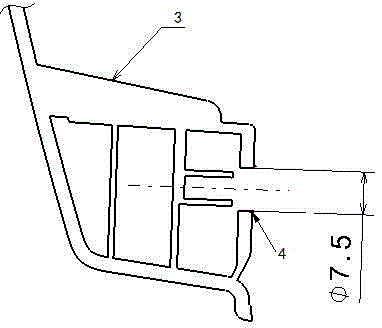

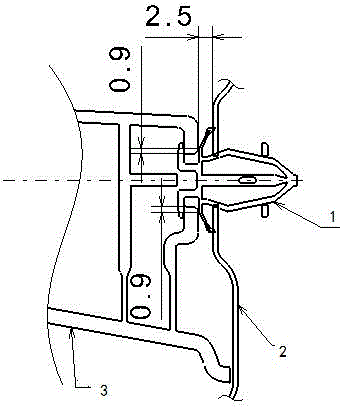

[0012] Improved buckle seat structure, which includes buckle 1, sheet metal 2 and door guard 3, the diameter of the installation hole 4 of the buckle seat is Φ9, and the fillet on the installation hole is R1, after this design is assembled , theoretically the gap between the buckle seat surface and the sheet metal surface is still 2.5, but after actual assembly, if there is still a gap between the sheet metal and the end face of the door guard, apply a force from the front of the door guard to push the buckle claws 5 Deformation, the door guard plate moves towards the sheet metal direction, "sucks" into the door guard plate, thereby pulling the door guard plate to the sheet metal at a distance of 0 to 1, compared with the traditional method, the contact area between the buckle and the door guard plate is 1.5 When it becomes 0.9, the contact are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com