A new type of submersible thruster impeller

A submersible flow propeller and impeller technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of large impeller diameter, increased unbalance, connection failure, etc., and achieve guaranteed strength and stiffness, improving stress conditions, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

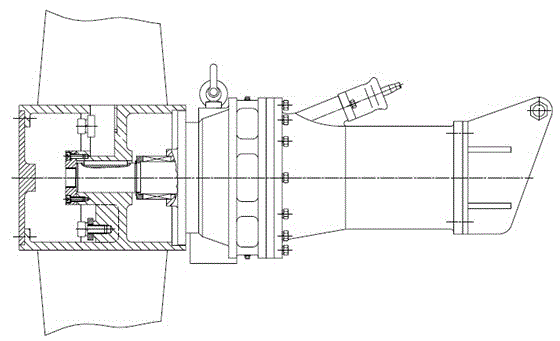

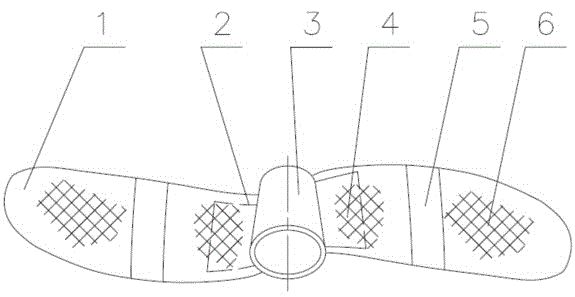

[0026] Such as figure 2 As shown, a novel submersible thruster impeller of the present invention includes a blade 1, a keel 2, a hub 3, an expansion resin 4, a rib 5, and a high-performance foam 6. The impeller is an integral impeller with two blades, and its appearance is made of reinforced glass fiber reinforced plastic material that wraps the hub 3 and the keel 2. Each impeller includes a hub 3 and two blades 1, the keel 2 is welded on the hub 3, and the rib 4 passes through The mold is fixed on the easily deformable position of the blade 1 to increase the rigidity, and the upper and lower parts of the blade 1 (the two blades are divided into two parts that are exactly the same and opposite in direction through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com