Compensation light source system and dynamic image detecting device for train operation fault

A technology for compensating light sources and optical fibers, applied in the field of lasers, it can solve the problems of camera exposure, incompatibility, limited rail space, etc., and achieve the effects of improving laser utilization, light intensity, and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

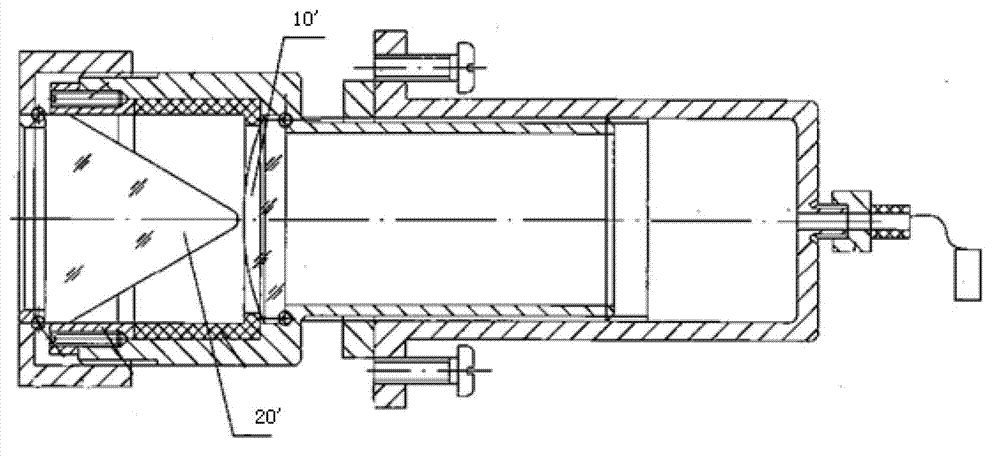

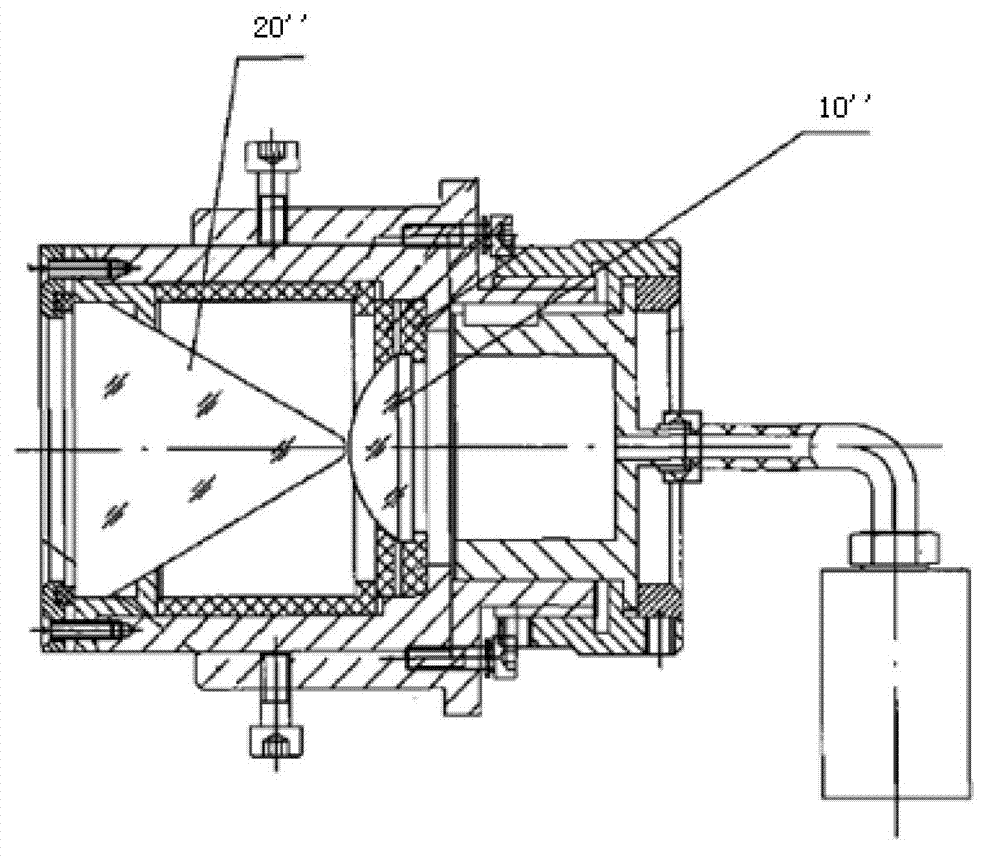

[0046] like Figure 4 As shown, according to an embodiment of the present invention, a compensation light source system is provided, including a laser generating device 50 with an optical fiber 51 and a beam shaping component. Wherein the laser generating device 50 is used for emitting laser beams. The optical fiber 51 has an optical output end, and the laser beam transmits from the optical output end after a certain distance is transmitted in the optical fiber 51 .

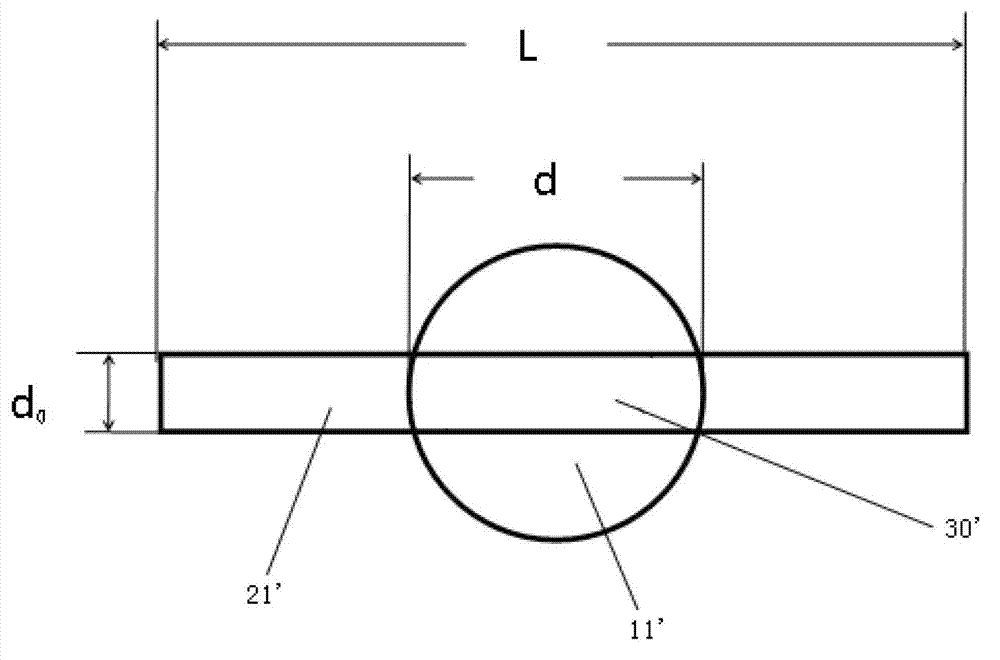

[0047] The beam shaping component is used to adjust the divergence angle of the laser beam so that the spot formed by the final projection of the laser beam meets the requirements of use. The beam shaping component includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com