Converter for an electrical machine, controller and method for operating a converter

一种逆变器、控制器的技术,应用在电动机控制、交流电动机控制、交流电动机的减速装置等方向,能够解决保护装置制造成本和所需空间大等问题,达到节约所需空间、节约制造费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

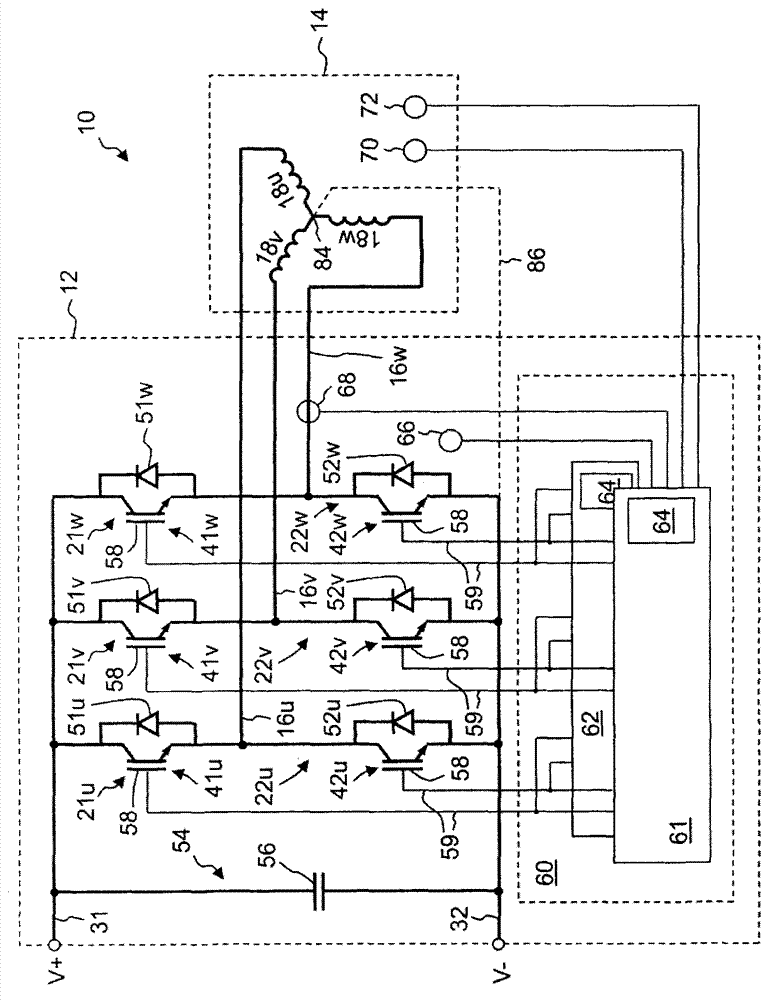

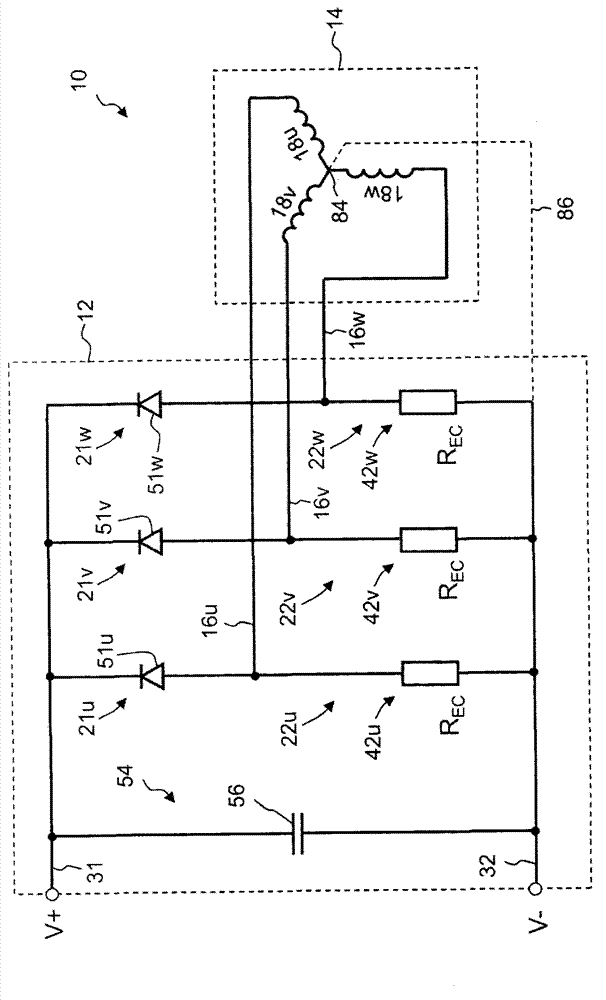

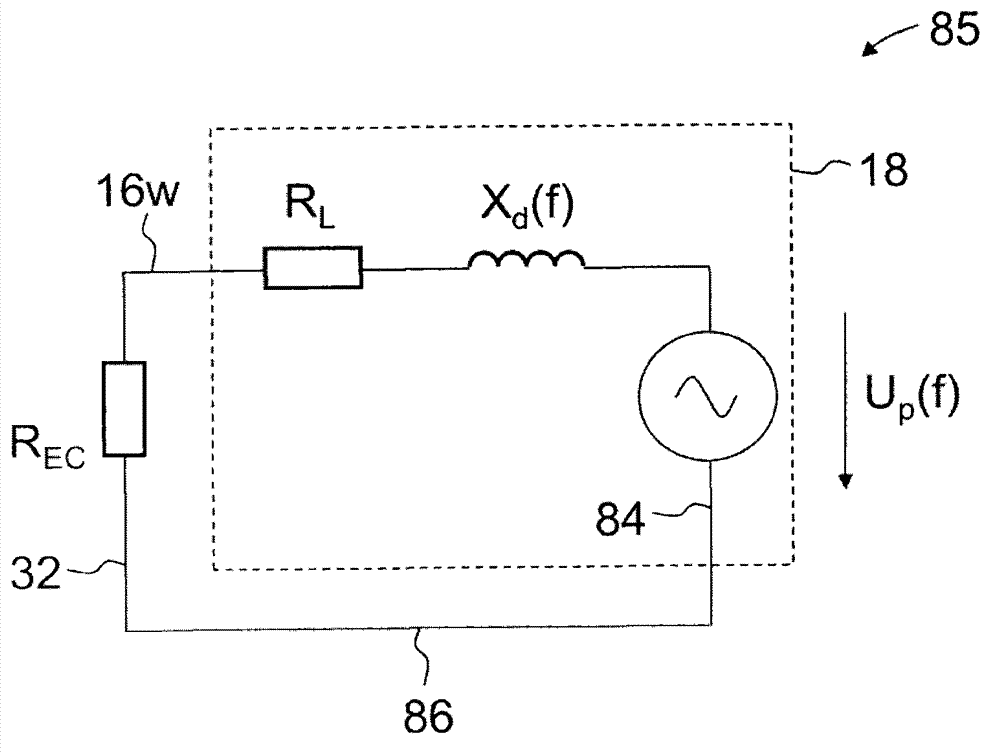

[0033] figure 1 The illustrated system 10 includes an inverter 12 and an electric motor 14 . The electric motor 14 is connected to the inverter 12 with three phase lines 16u, 16v, 16w. The motor 14 is permanently excited. The permanent magnets of the electric motor 14 (not shown in the accompanying drawings) are usually fixed in the rotor of the electric motor 14 (not shown in the drawings), and the windings 18u, 18v, 18w of the electric motor 14 are all arranged between the stators of the electric motor 14 middle. The drawing shows how the winding 18 is connected to the phase conductor 16 in a star connection. Another alternative, not shown in the figures, is to connect the winding 18 to the phase line 16 in a delta connection. The inverter 12 comprises a first switching circuit 21u, 21v, 21w per phase line 16 for temporarily connecting the phase line 16 with the supply line 31 having a positive potential V+. Furthermore, the inverter 12 also includes a second switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com