Roller cutter for shredder, and shredder

A paper shredder and hob technology, applied in grain processing, etc., can solve the problem of increased working hours and achieve the effect of reducing metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060] A first embodiment of the present invention will be described below with reference to the drawings.

[0061] The shredder S according to the present embodiment is a so-called residential / SOHO shredder, and is suitable for home and / or small-scale offices called SOHO. Lift.

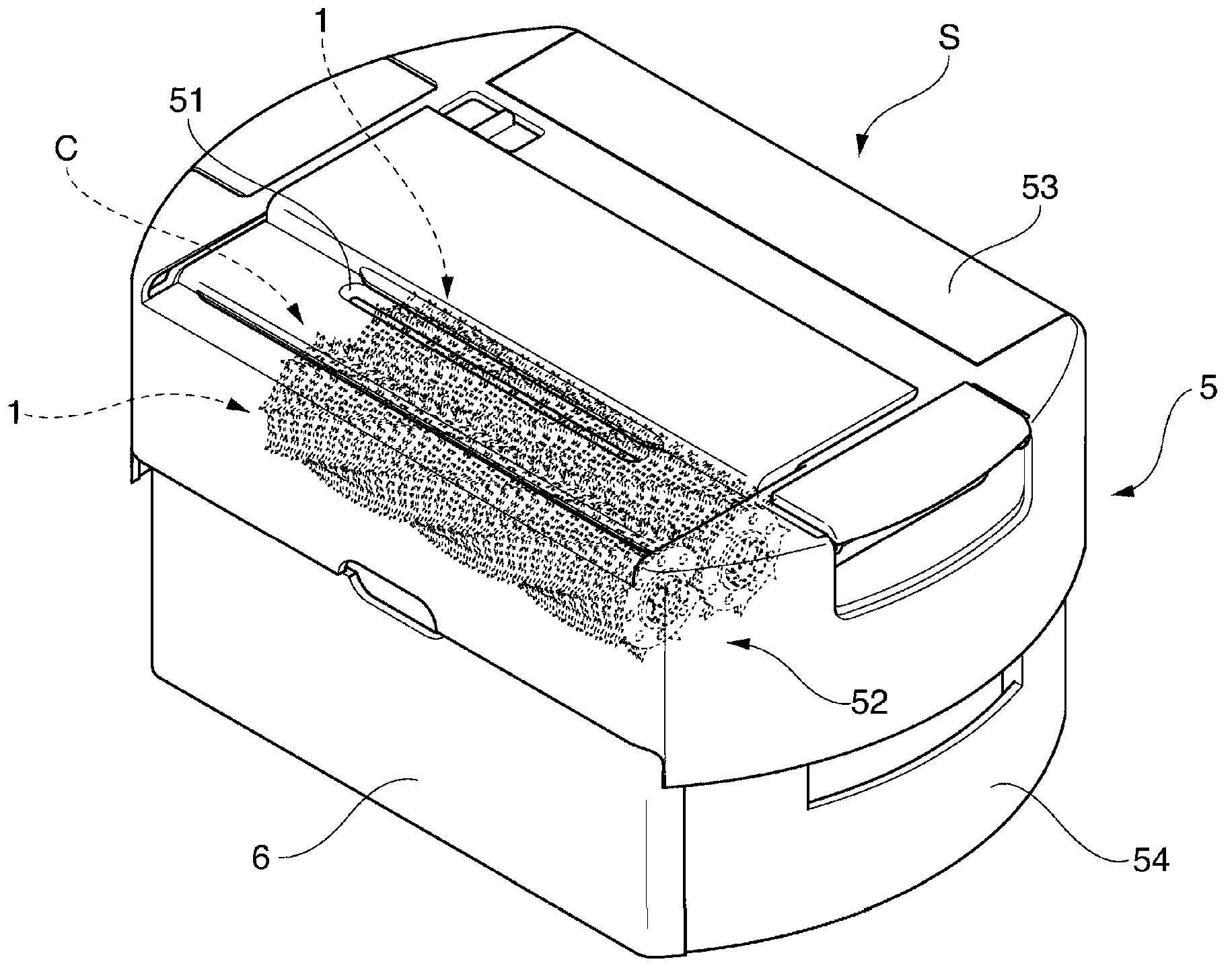

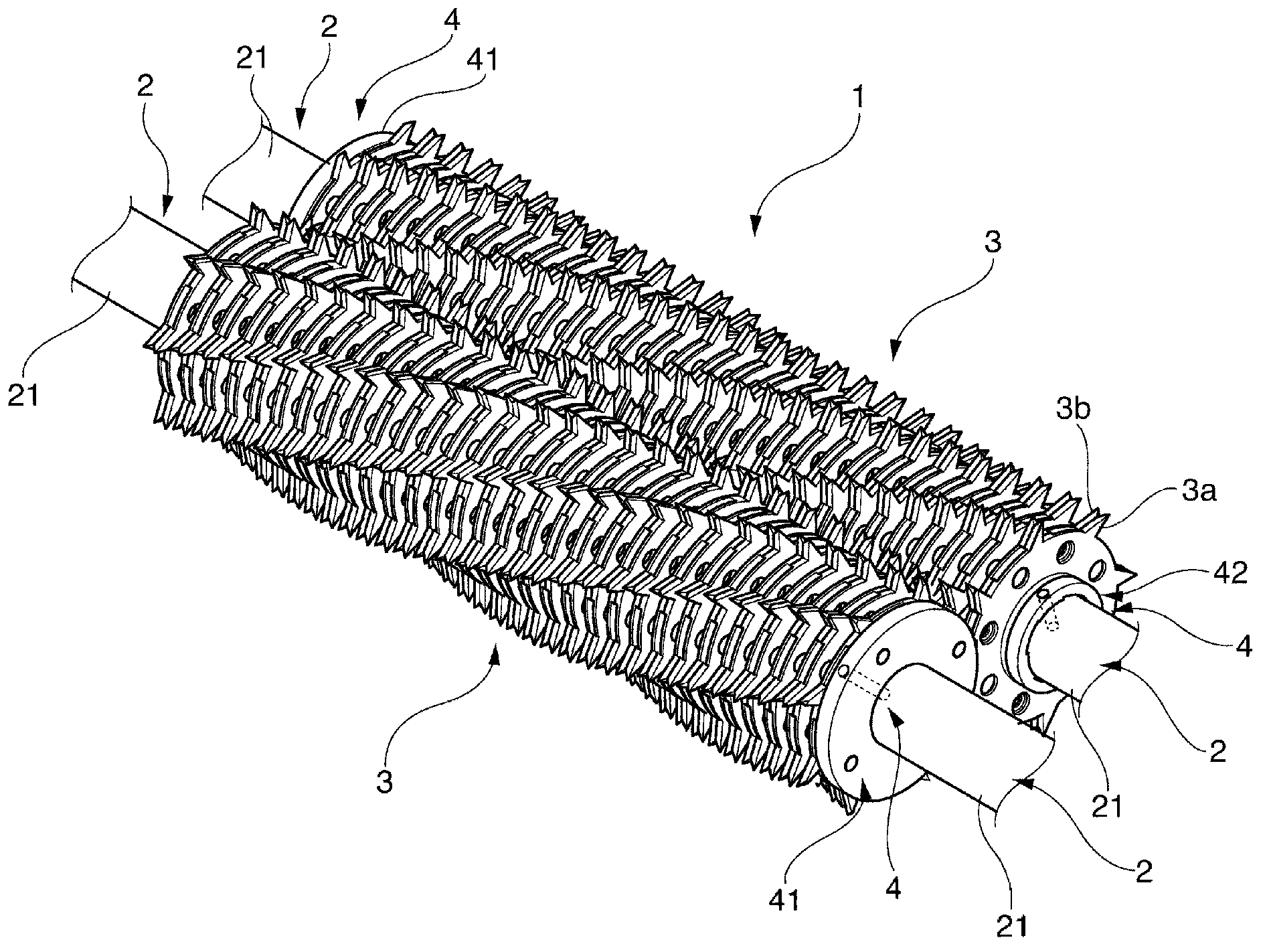

[0062] Such as figure 1 As shown, the paper shredder S mainly has: a single housing 5; a paper shredding mechanism C, which is used to shred paper and other shredded objects in the housing 5, which is indicated by a dotted line in the figure; A drawer-shaped chip container 6 that crushes chips and discharges them out of the casing 5 . In addition, the shredder S according to this embodiment is further provided with a drive mechanism for driving the shredder mechanism C, an operation unit having a main power switch, etc. The interlock mechanism and the like for making the crushing blade 3 inoperative are described below. However, since various existing configurations can be adopted for these compon...

no. 2 approach

[0097] Use below Figure 19 to Figure 26 Modifications of this embodiment will be described. Also in this second embodiment, as in the above-mentioned first embodiment, the same reference numerals are assigned to components corresponding to those in the above-mentioned embodiment, and detailed description thereof will be omitted.

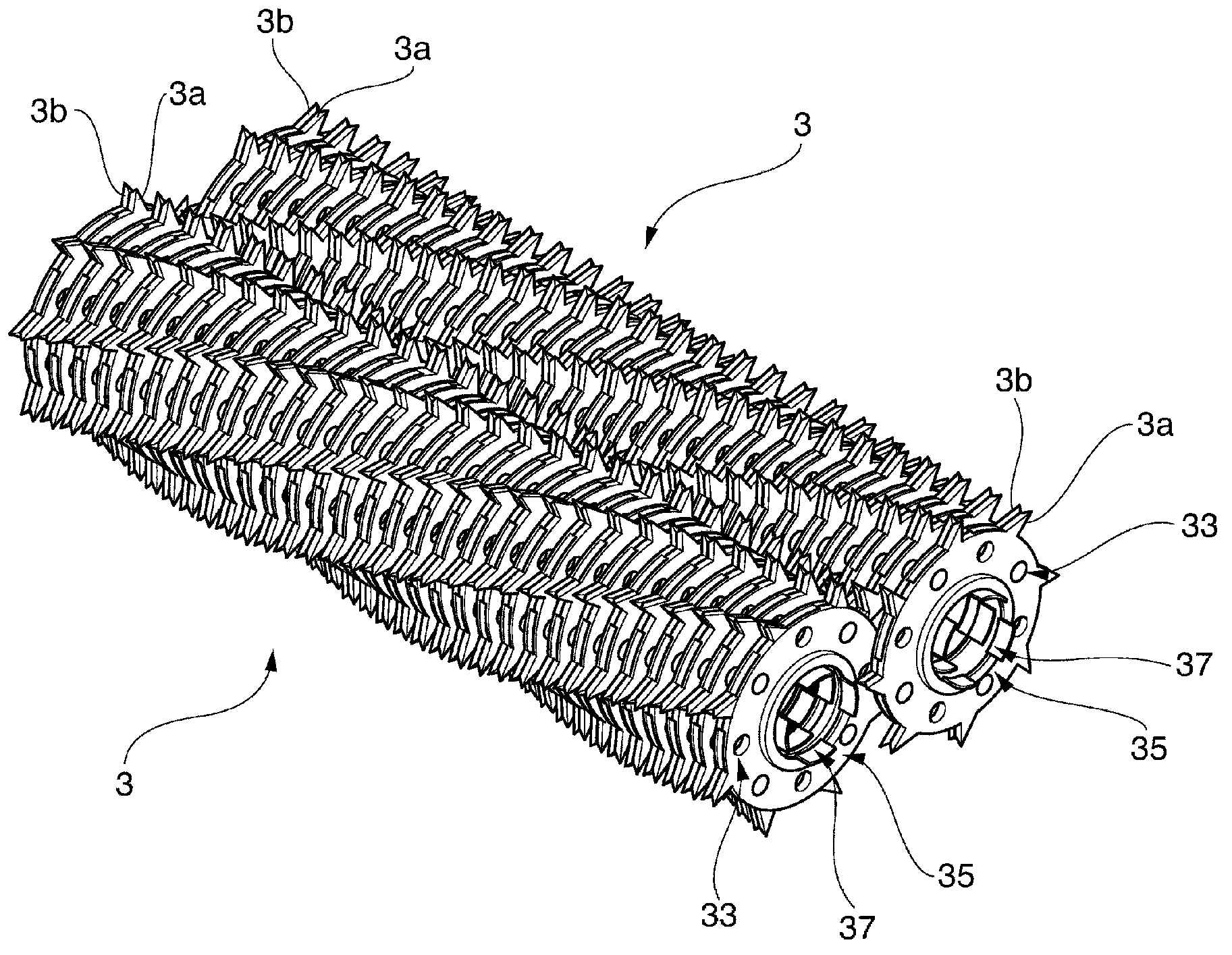

[0098] As shown in the figure, the crushing blade 3 is constituted by at least fitting the inner sides of two paired discs 3a, 3b. Furthermore, these disks 3a and 3b have the following constituent elements as the constituent elements of the crushing blade 3 similarly to the first embodiment described above. That is, the pulverizer blade 3 has a folded portion 31 , a fitting portion 33 , a partition portion 34 , and a shaft insertion hole 37 for inserting the pulverizer blade 3 itself through the rotation shaft. In addition, the same applies to the point that the engaging portion 35 is arranged such that the disk 3 b is offset at a predetermined an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com