Three-dimensional printing line light condensing source adopting solar energy and printing method

A printing line, solar energy technology, applied in optics, optical components, instruments, etc., can solve the problem of high cost of laser energy, achieve the effect of small effective reflection area, small rotation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

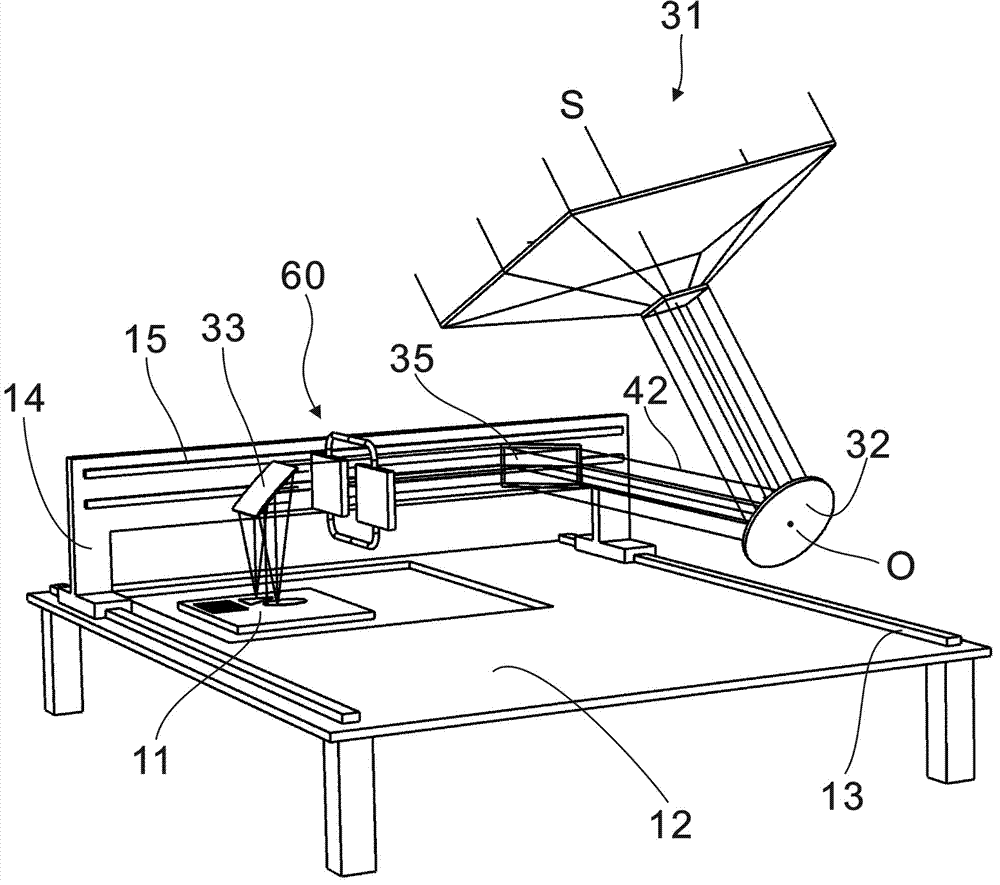

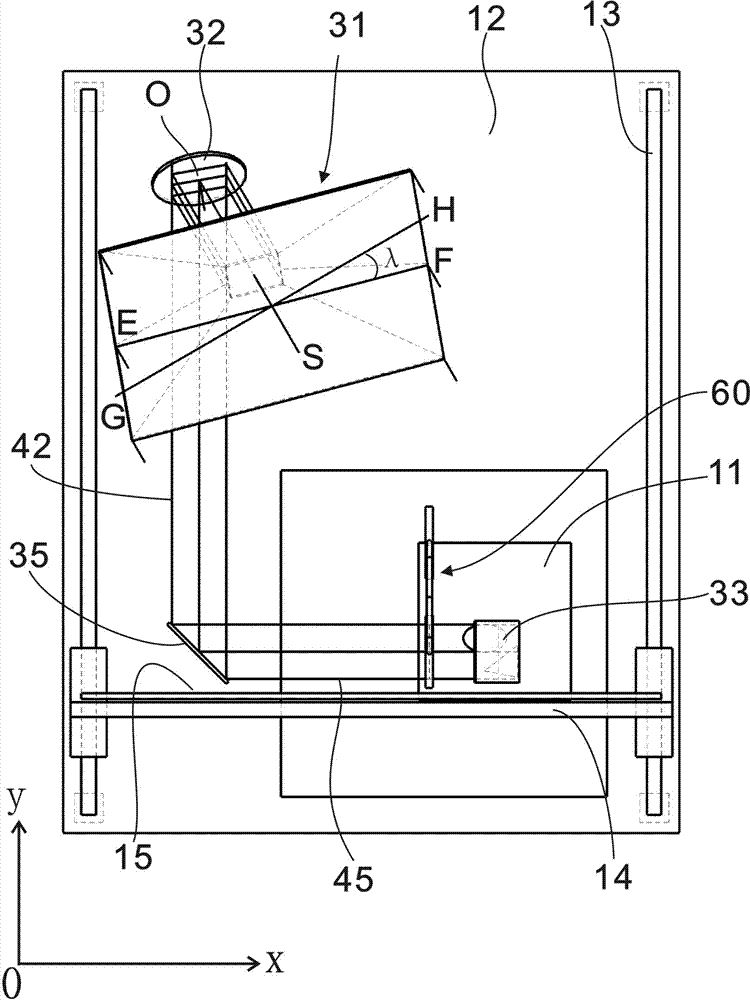

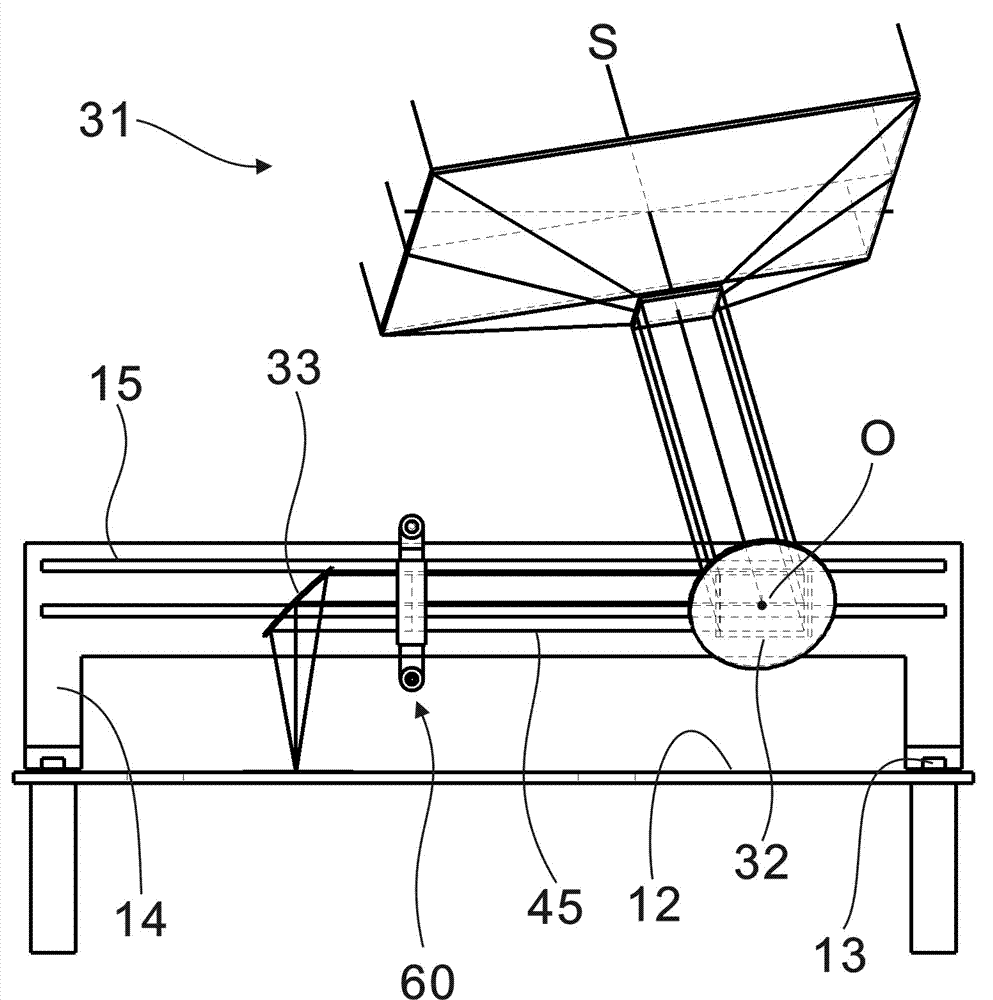

[0033] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention provides a three-dimensional printing line concentrating light source utilizing solar energy, including: a sintering surface 11, a working platform 12, a meridian linear track 13, and a meridian translation support 14. Latitude linear track 15, concentrator 31, horizontal meridian mirror 32, horizontal latitude mirror 35, parabolic mirror 33, light shield 60; sintering surface 11 is composed of materials with smaller particles Horizontal plane; the upper surface of the working platform 12 is a horizontal plane, and the meridian linear track 13 is fixed on the upper surface of the working platform 12, facing the north-south direction; the meridian translation support 14 is installed on the meridian linear track 13, and can move horizontally along the north-south direction; The latitudinal linear track 15 and the horizontal latitudinal reflector 35 are fixedly installed on the warp-direction translation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com