Ventilation system of multi-stage machine station in mine

A ventilation system and mine technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve problems such as difficult management of multi-machine stations and multi-fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

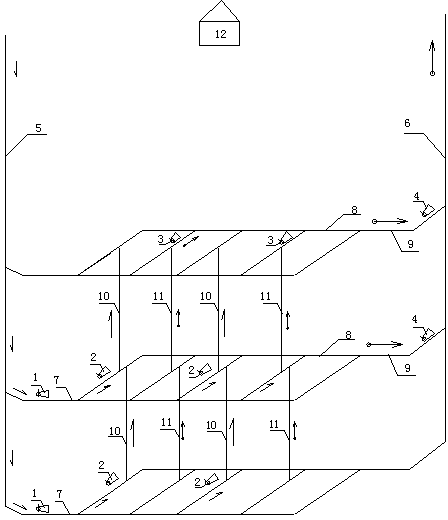

[0032] In order to further describe the present invention, the mine multi-stage machine station ventilation system of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

[0033] exist figure 1 In the schematic diagram of the four-stage ventilation system of the mine multi-stage ventilation system shown in the present invention, the mine ventilation system is provided with a first-level station 1 in the main air inlet lane 7, and a second station is arranged in the joint lane of the air inlet skyway 10 2. Set up a level III machine station 3 in the joint lane of the return air shaft 11, set up a level IV machine station 4 in the main return air lane 9, and set up a mine ground general monitoring room 12 on the mine ground.

[0034] exist figure 1The three middle sections shown in , respectively represent the first middle section, the second middle section, and the third middle section from top to bottom. The surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com