Coal seam water injection system

A coal seam water injection and coal seam technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as poor coal seam water injection work, limited pressure, and inability to achieve high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

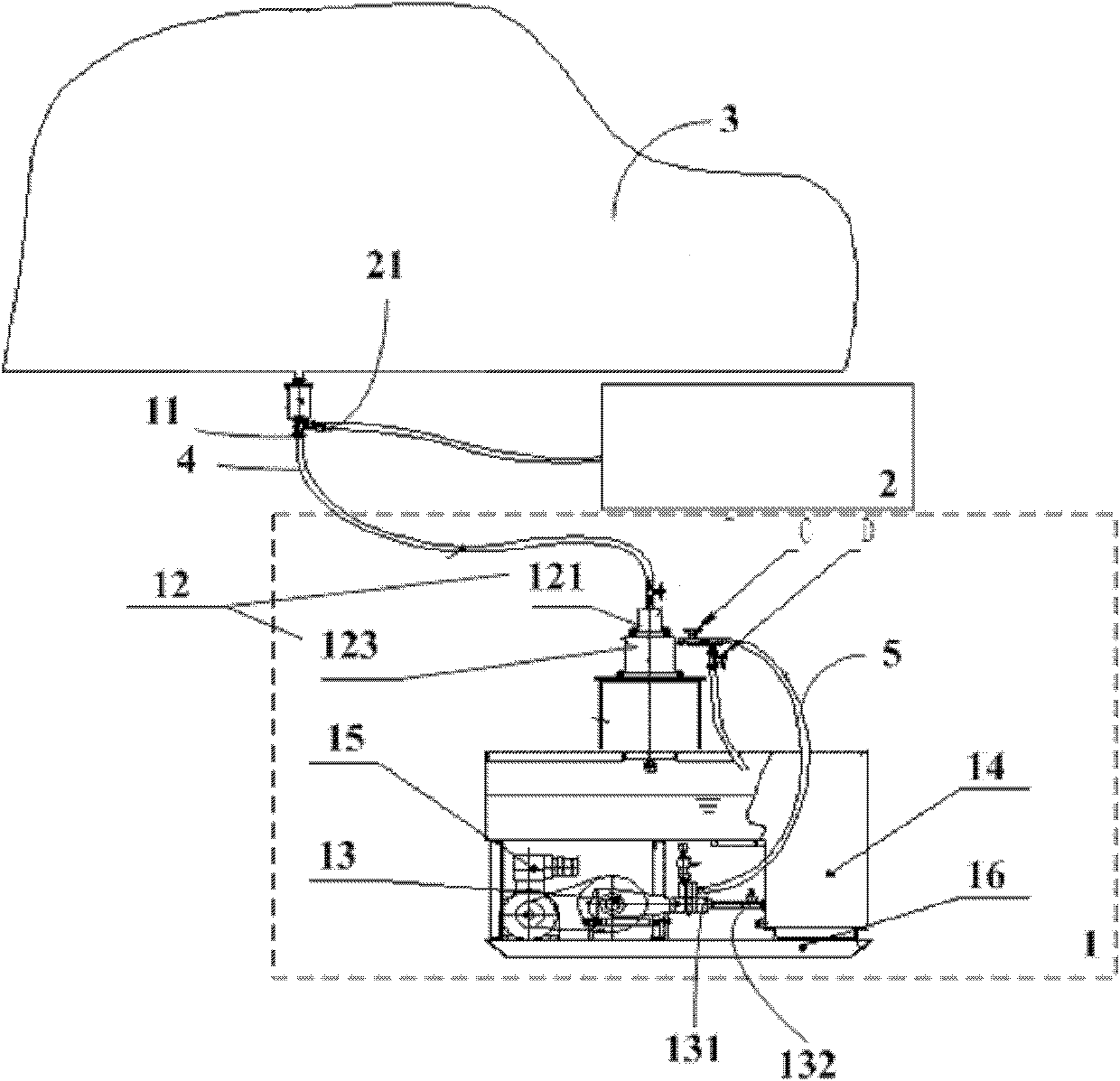

Embodiment 1

[0054] figure 1 It is a schematic diagram of the coal seam water injection system provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a coal seam water injection system, which includes: a pulse power subsystem 1 and a water injection subsystem 2; the water outlet 21 of the water injection subsystem 2 communicates with the coal seam 3 to be water injected in the set area, so as to inject water into the coal seam to be water injected 3. Water injection; the liquid outlet 11 of the pulse power subsystem 1 communicates with the coal seam 3 to be water injected in the set area, so as to provide hydraulic pulses to the coal seam 3 to be water injected in the area.

[0055] There is no limitation on how the pulse power subsystem and the water injection subsystem are connected to the coal seam to be water injected. They can be connected to the coal seam to be water injected in the same area through two pipes, or connected to the coal seam ...

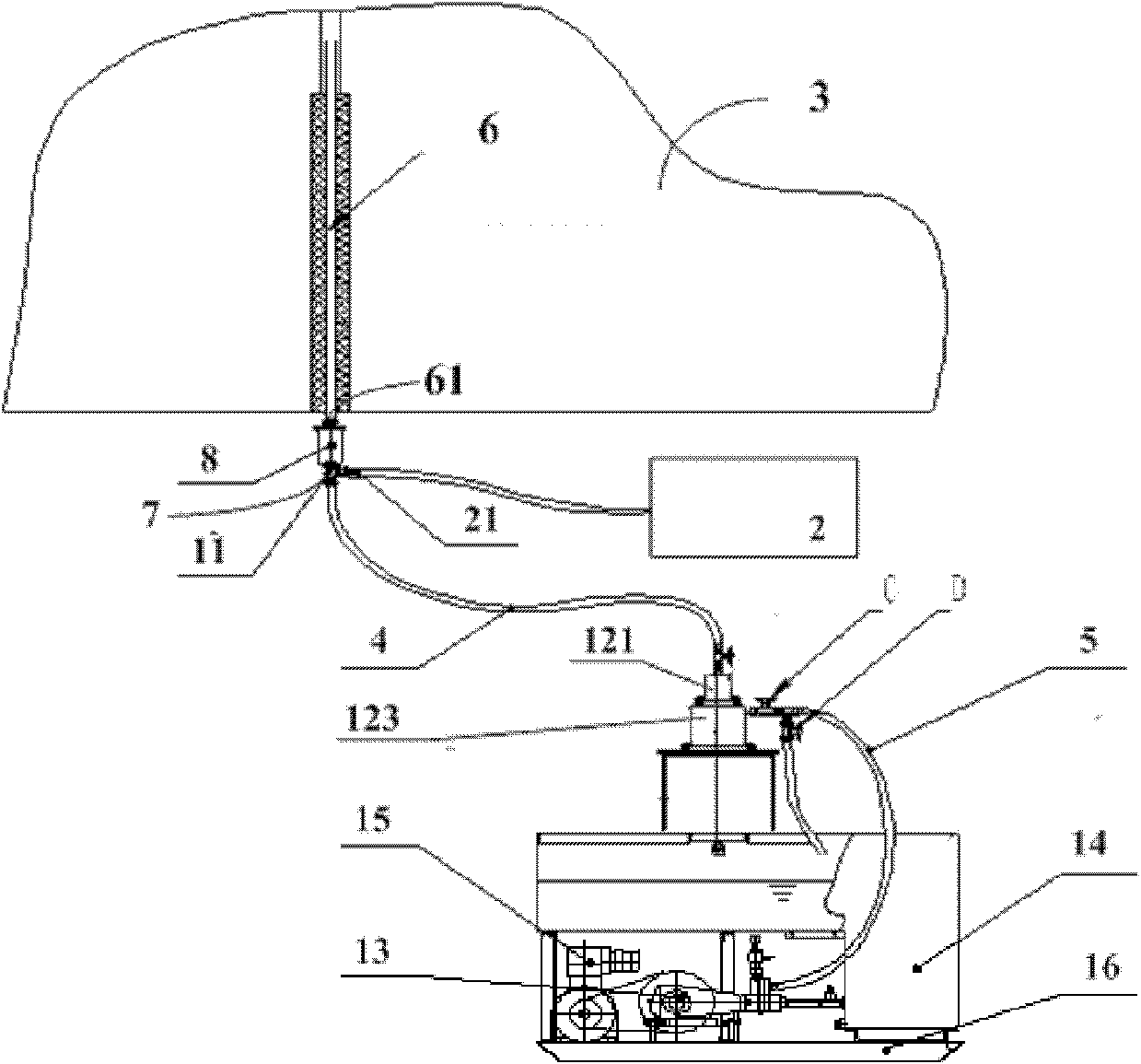

Embodiment 2

[0063] figure 2 It is a schematic diagram of the coal seam water injection system provided by Embodiment 2 of the present invention. Embodiment 2 of the present invention is based on the technical solution of Embodiment 1. Preferably, the coal seam water injection system also includes a water injection pipe 6. The pipe at the end of the water injection pipe 6 outlet is clamped in the coal seam 3 to be water injected. The inlet of the water injection pipe 6 61 is located outside the coal seam 3 to be injected with water, and the inlet 61 communicates with the water outlet 21 and the liquid outlet 11 respectively.

[0064] The pulse power subsystem and the water injection subsystem are connected to the coal seam to be injected through the same water injection pipe, which can simplify the structure of the whole system. In practical applications, sealing materials can also be arranged around the water injection pipe to avoid the influence of cinder on the water injection pipe. ...

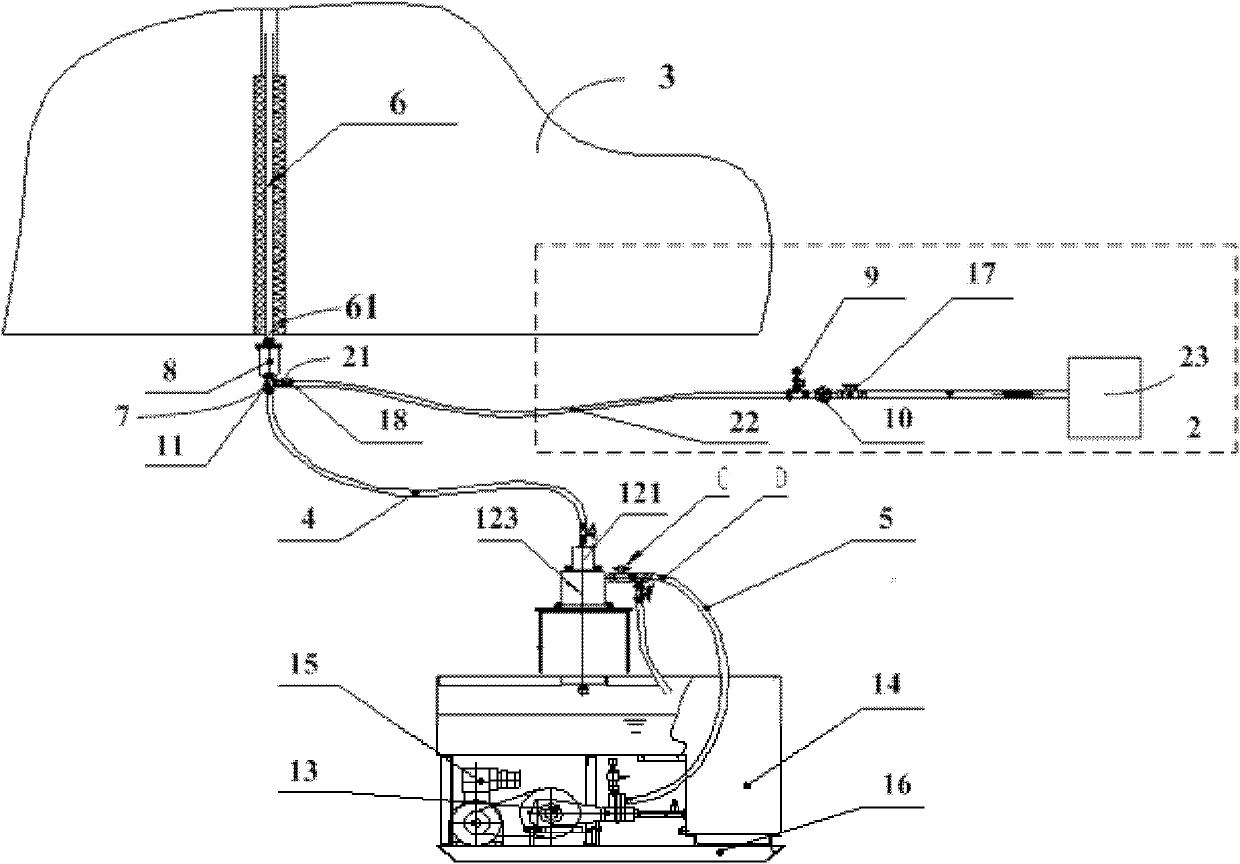

Embodiment 3

[0070] image 3 It is a schematic diagram of the coal seam water injection system provided by Embodiment 3 of the present invention. Embodiment 3 of the present invention is preferably based on the technical solutions of the foregoing embodiments. The water injection subsystem 2 comprises a static pressure water injection pipe 22 and a static pressure pump 23; the water outlet of the static pressure water injection pipe 22 is used as the water outlet 21 of the water injection subsystem; A pressure pump (not shown) is in communication; the hydrostatic pressure pump is used to pump water into the hydrostatic injection pipe 22 .

[0071] After adding the pulse power subsystem, the structure of the water injection subsystem will not be affected. In addition, the pulse power subsystem is set up, and the existing water injection subsystem can be used to inject water into the coal seam, and the water injection effect is good.

[0072] In practical application, a one-way valve 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com