Nuclear power plant passive pulse cooling method and system

A passive, nuclear power plant technology, applied in the field of nuclear power, can solve the problems of difficult transformation, difficult application and high cost, and achieve the effects of delaying the melting time, stabilizing the temperature of the primary circuit, and helping to control accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

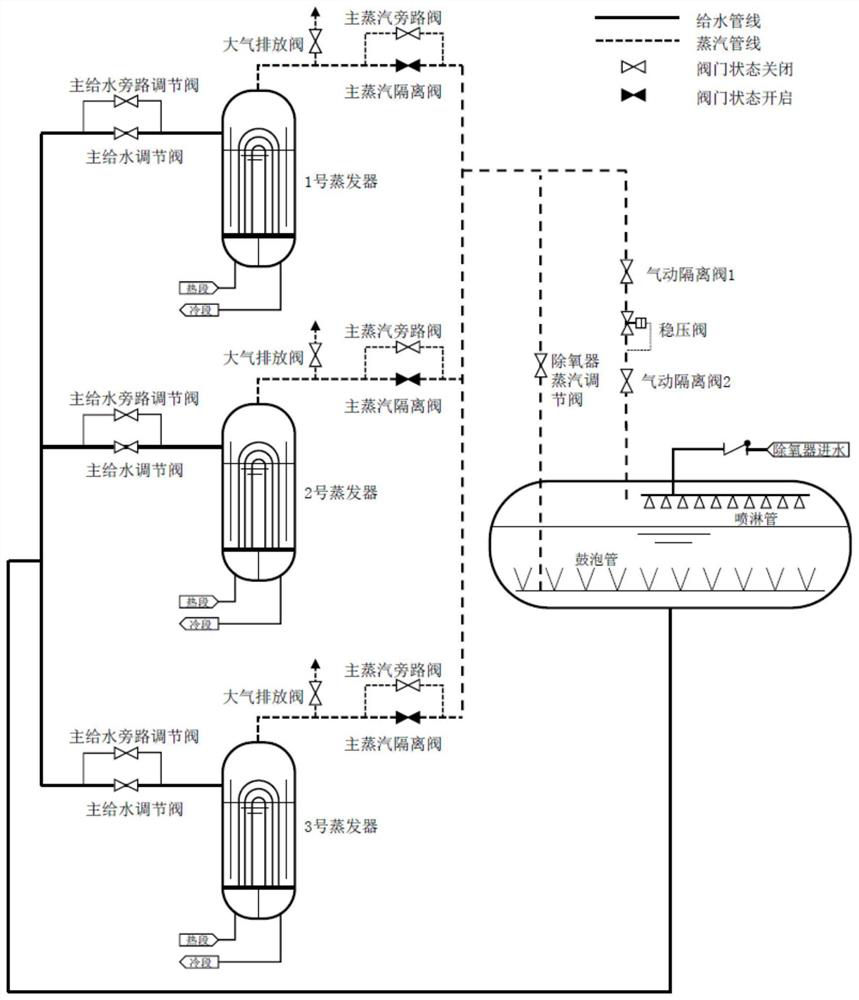

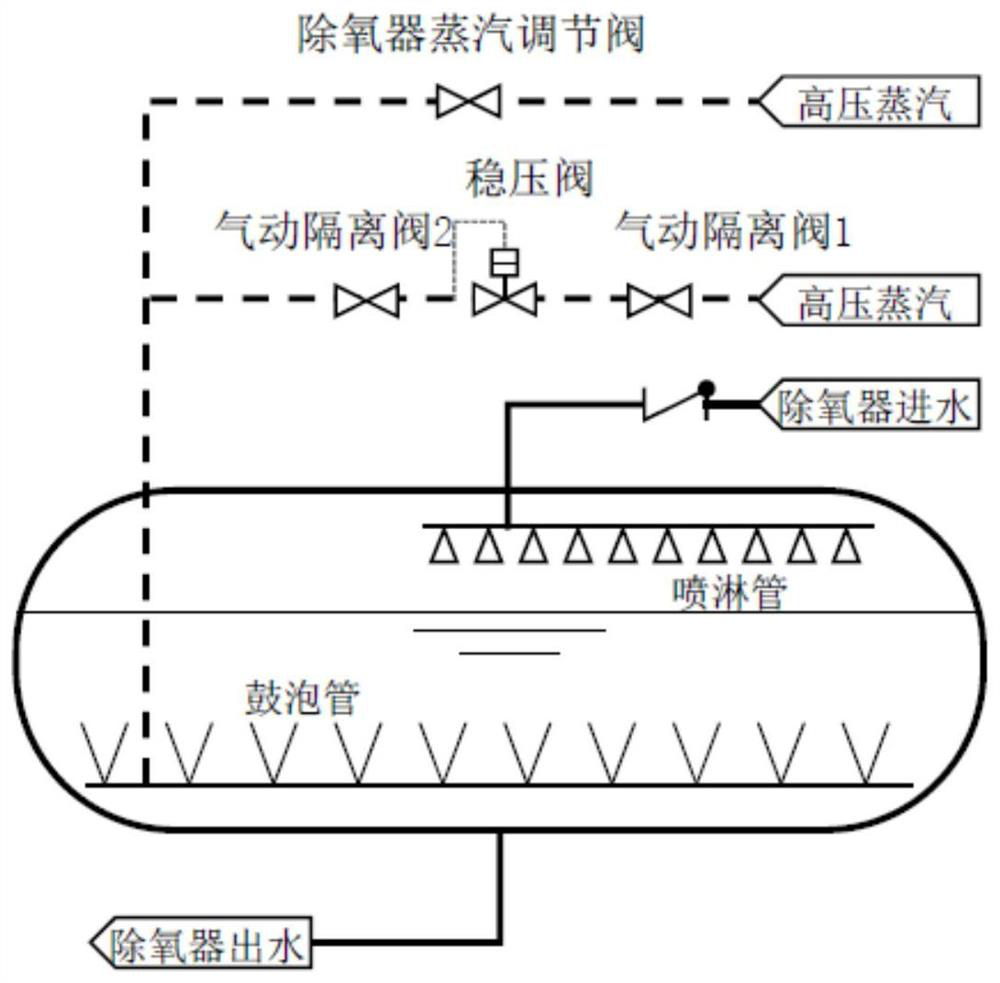

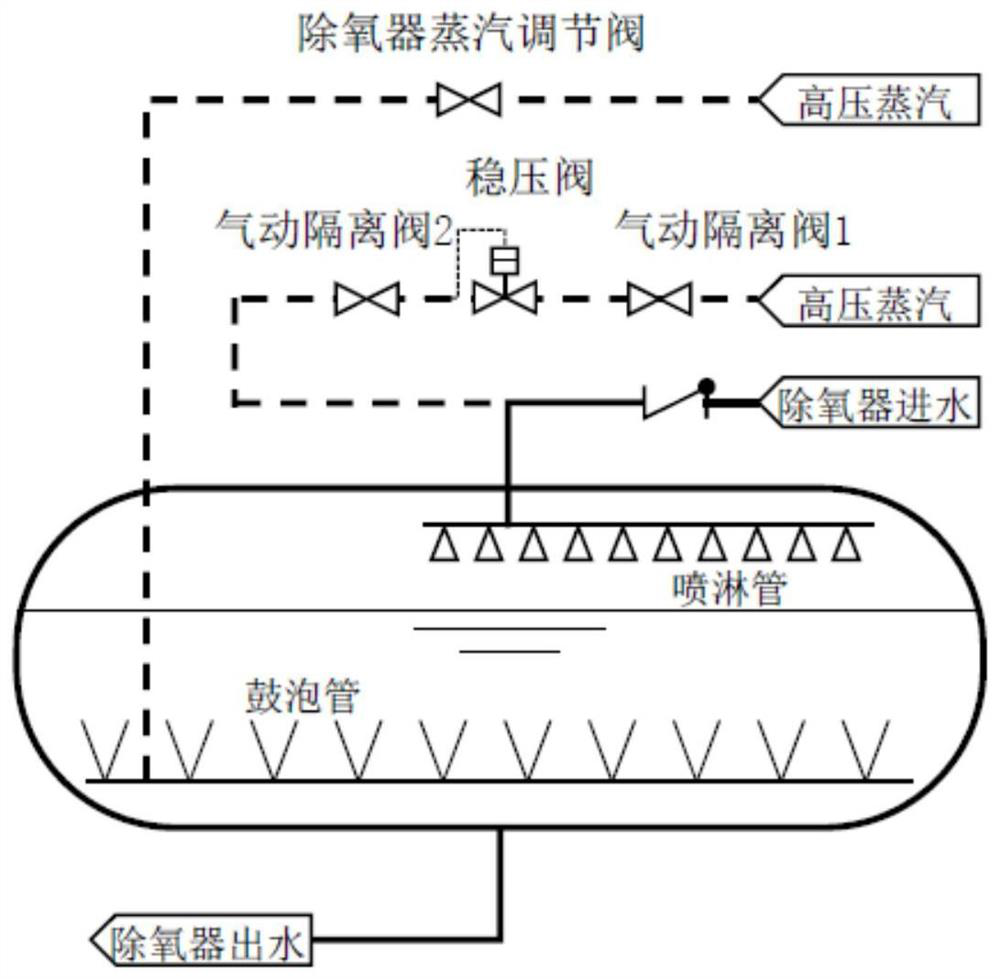

[0055] Due to the power outage of the whole plant, all rotating equipment failed, and water could not be supplied to the steam generator through the water pump. The present invention can use the nuclear steam supply system and the high-temperature and high-pressure steam in the high-pressure evaporator to pressurize the deaerator in a passive way, so as to inject the water in the water tank of the deaerator into the low-pressure evaporator, thereby Cool the core.

[0056] The general idea of the present invention is as follows: in the event of an accident of losing all water supply or a superimposed loss of all water supply in the whole plant, firstly isolate all the steam pipelines and water supply pipelines of the evaporator, and then separate the functions of all the evaporators, according to the accident According to the requirements of the treatment strategy, select the operation mode, divide all the steam generators into two parts, the power evaporator and the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com